Members of the Xe-100 reactor protection system team and the first set of prototype equipment. (Photo: X-energy)

X-energy, developer of the Xe-100 small modular reactor, has delivered the first of four sets of equipment for the Xe-100 reactor protection system (RPS) prototype, marking the latest milestone in the company’s efforts under the Department of Energy’s Advanced Reactor Demonstration Program (ARDP).

A screen shot of a YouTube video of the DOE’s U-233 Initial Processing Campaign at Oak Ridge National Laboratory.

Isotek, the Department of Energy contractor responsible for overseeing the inventory of uranium-233 at Oak Ridge National Laboratory and preparing it for removal from the site, said it plans to resume preparations for processing high-dose U-233 in March. The company was forced to suspend its operational readiness review of the Initial Processing Campaign at Oak Ridge in January due to issues related to COVID-19, as well as difficulties operating in colder temperatures.

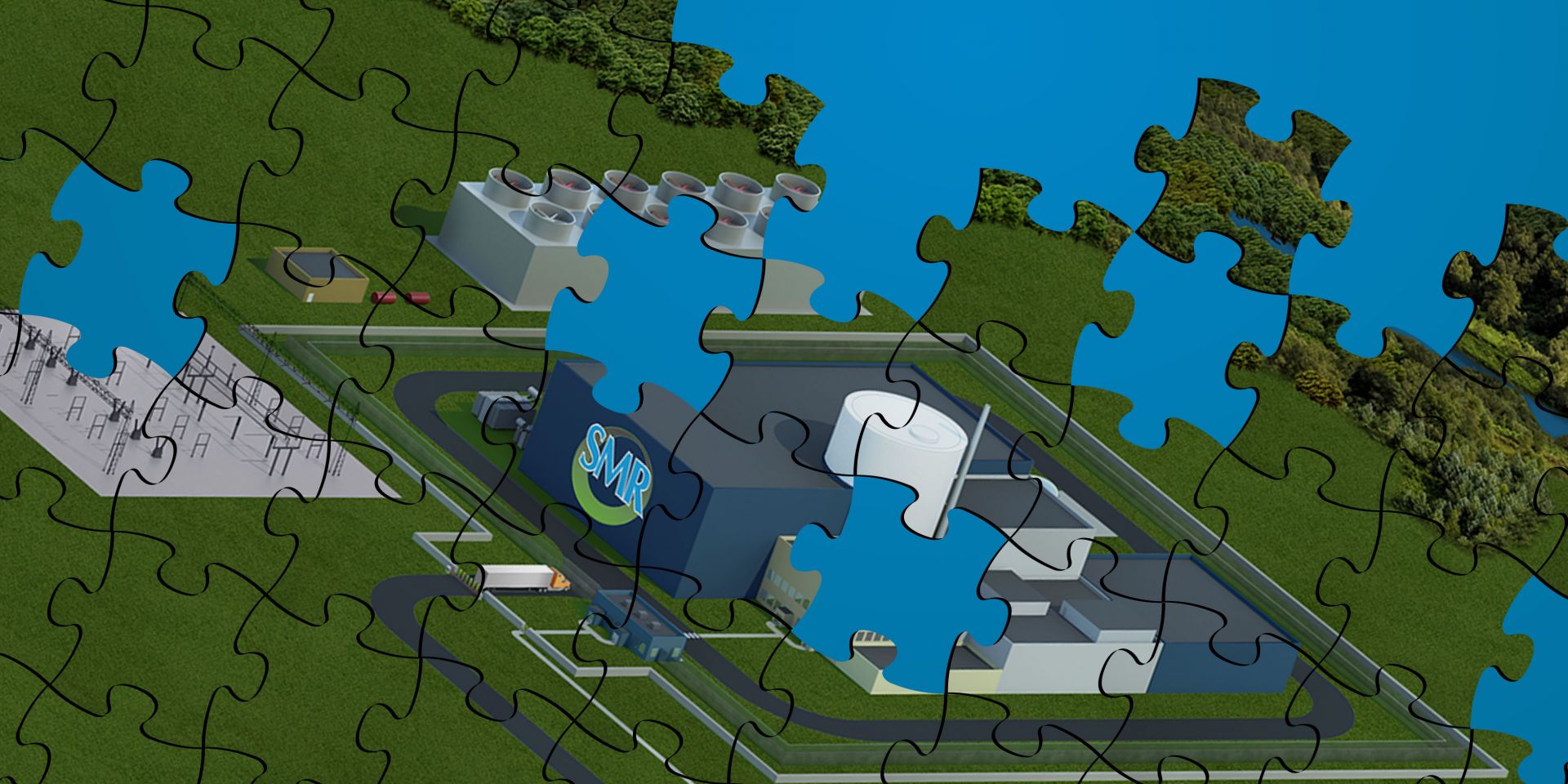

An advanced nuclear reactor technology park is hoped for the 935-acre Clinch River site. Image: TVA

The Tennessee Valley Authority’s board of directors has given the go-ahead for a program that will explore the development and potential deployment of small modular reactors as part of the utility’s decarbonization strategy.

A rendering of the Natrium plant. (Image: TerraPower)

Natrium, a 345-MWe sodium fast reactor with a molten salt energy storage system, was developed by TerraPower and GE Hitachi Nuclear Energy. TerraPower is planning to build the first Natrium demonstration reactor by 2028 with 50-50 cost-shared funding of about $2 billion from the Department of Energy’s Advanced Reactor Demonstration Program. And for the requisite data and testing of reactor components to support that deployment, TerraPower is looking to Japan—a country with decades of experience developing sodium fast reactor designs and testing infrastructure.

Artist's rendition of the Versatile Test Reactor. (Source: DOE)

The Molten Chloride Reactor Experiment will be built at Idaho National Laboratory to demonstrate criticality in a fast-spectrum salt-cooled reactor within five years. (Image: Southern Company)

(Click photo to enlarge) One of 16 AC100M gas centrifuges built by Centrus Energy for HALEU production in Piketon, Ohio. (Photo: Centrus Energy)

For years, pressure has been building for a commercial path to a stable supply of high-assay low-enriched uranium (HALEU)—deemed essential for the deployment of advanced power reactors—but advanced reactor developers and enrichment companies are still watching and waiting. In contrast, the uranium spot price soared after Sprott Physical Uranium Trust, a Canadian investment fund formed in July, began buying up U3O8 supplies, causing the price to increase over 60 percent, topping $50 per pound for the first time since 2012. Fueled by growing acknowledgment that nuclear power is a necessary part of a clean energy future, uranium is the focus of attention from Wall Street to Capitol Hill.

A future TerraPower plant visualization. (Graphic: TerraPower)

TerraPower has a design for a sodium-cooled fast reactor and federal cost-shared demonstration funding from the Department of Energy. Its partner, PacifiCorp, has four operating coal-fired power plants in the state of Wyoming. On June 2, together with Wyoming Gov. Mark Gordon and others, the companies announced plans to site a Natrium reactor demonstration project at a retiring coal plant in Wyoming, with a specific site to be announced by the end of 2021.

May 21, 2021, 2:41PMNuclear NewsCharles Forsberg and Eric Ingersoll TerraPower and GE Hitachi Nuclear Energy jointly developed the sodium-cooled Natrium reactor with the turbine hall, nitrate heat storage tanks, and cooling towers separated from the reactor at the back of the site.

The viability of nuclear power ultimately depends on economics. Safety is a requirement, but it does not determine whether a reactor will be deployed. The most economical reactor maximizes revenue while minimizing costs. The lowest-cost reactor is not necessarily the most economical reactor. Different markets impose different requirements on reactors. If the capital cost of Reactor A is 50 percent more than Reactor B but has characteristics that double the revenue, the most economical reactor is Reactor A.

The most important factor is an efficient supply chain, including on-site construction practices. This is the basis for the low capital cost of light water reactors from China and South Korea. The design of the reactor can significantly affect capital cost through its impact on the supply chain. The question is, how can advanced reactors boost revenue and reduce costs?

.jpg)