Artist's rendering of the proposed TRISO-X Fuel Fabrication Facility (TF3) at the Horizon Center Industrial Park, in Oak Ridge, Tenn. (Image: X-energy)

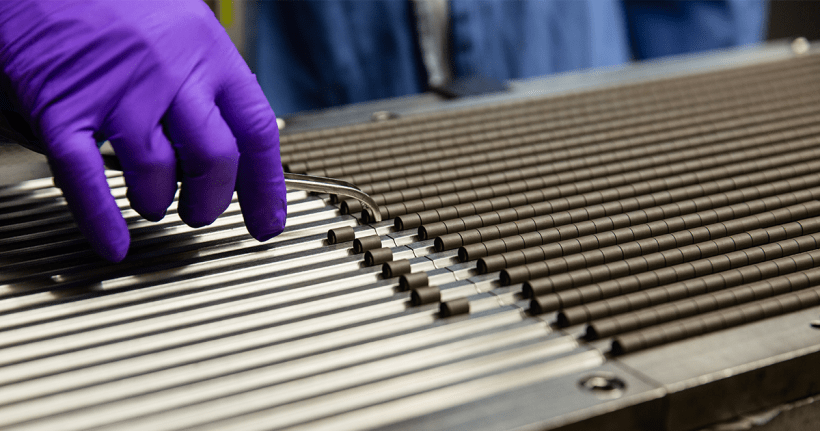

X-energy has announced that its wholly owned subsidiary, TRISO-X, plans to build the TRISO-X Fuel Fabrication Facility, dubbed TF3, at the Horizon Center Industrial Park in Oak Ridge, Tenn. X-energy has produced kilogram quantities of fuel at its pilot plant at Oak Ridge National Laboratory through a public-private partnership.

The commercial plant will use high-assay low-enriched uranium (HALEU) to produce TRISO particles, which are fabricated into fuel forms, including the spherical graphite “pebbles” needed to fuel the company’s Xe-100 high-temperature gas reactor. Site preparation and construction are expected to get underway in 2022, and commissioning and start-up are scheduled for as early as 2025, according to X-energy.

Ultra Safe Nuclear staff in front of the new pilot fuel fabrication facility in Oak Ridge, Tenn. (Photo: USNC)

Ultra Safe Nuclear Corporation (USNC), an advanced reactor and reactor fuel developer, announced last week that it plans to begin operations this summer at its Pilot Fuel Manufacturing (PFM) facility in Oak Ridge, Tenn., pending the receipt of the requisite state and local permits. The facility is located in the East Tennessee Technology Park, site of the Manhattan Project’s K-25 gaseous diffusion plant. USNC purchased an 8.7-acre site—which included a preexisting industrial building—from Heritage Center LLC in 2021.

High-voltage power lines carry electricity generated by the Tennessee Valley Authority to Oak Ridge National Laboratory. (Photo: Dobie Gillispie/ORNL, DOE)

The Tennessee Valley Authority and Oak Ridge National Laboratory have signed a memorandum of understanding to advance decarbonization technologies in pursuit of the federal government’s net-zero-by-2050 goal, the utility and the lab announced yesterday in a joint press release.

A screen shot of a YouTube video of the DOE’s U-233 Initial Processing Campaign at Oak Ridge National Laboratory.

Isotek, the Department of Energy contractor responsible for overseeing the inventory of uranium-233 at Oak Ridge National Laboratory and preparing it for removal from the site, said it plans to resume preparations for processing high-dose U-233 in March. The company was forced to suspend its operational readiness review of the Initial Processing Campaign at Oak Ridge in January due to issues related to COVID-19, as well as difficulties operating in colder temperatures.

ADOPT fuel pellets developed by Westinghouse through the DOE's Accident Tolerant Fuel Program. (Photo: Westinghouse)

Westinghouse Electric Company and Southern Nuclear have agreed to a plan to install four Westinghouse lead test assemblies in Vogtle-2, a 1,169-MWe pressurized water reactor located in Waynesboro, Ga. Four lead test assemblies containing uranium enriched up to 6 percent U-235 will be loaded in Vogtle-2 in 2023, marking the first time that fuel rods with uranium enriched above 5 percent U-235 are put in use in a U.S. commercial power reactor.

Kurt Terrani observing a chemical vapor infiltration furnace at ORNL during densification of additively manufactured nuclear-grade silicon carbide. (Photo: Carlos Jones/ORNL/DOE)

Ultra Safe Nuclear Corporation (USNC), a Seattle-based reactor developer, has licensed an additive manufacturing technique developed at the Department of Energy’s Oak Ridge National Laboratory to print refractory materials into structural and core components for the company’s microreactor designs.

The Summit supercomputer at Oak Ridge National Laboratory began operations in 2018. (Photo: ORNL)

The Department of Energy has announced $9.25 million for research into the behavior and properties of structural materials under molten salt reactor conditions through collaborations using the DOE’s high-performance supercomputers.

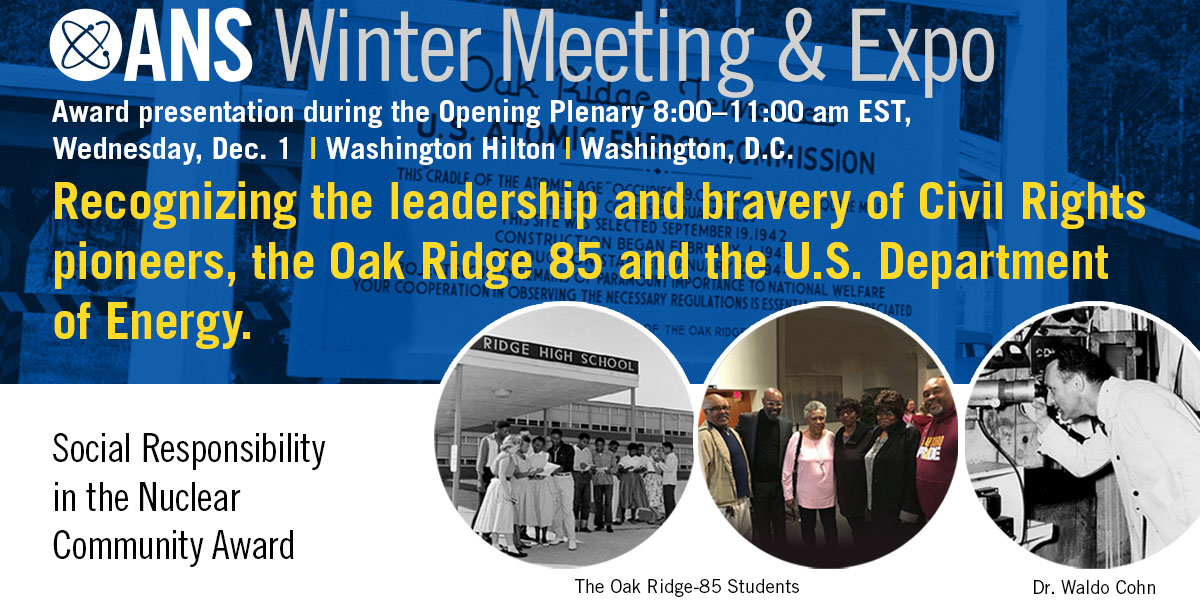

ANS presented Civil Rights-era students and the U.S. Dept. of Energy with inaugural award for integrating first public schools in the southeast U.S.

The American Nuclear Society (ANS) has honored eighty-five Black former students from Tennessee, known as the Scarboro-Oak Ridge, TN 85, and the U.S. Department of Energy (DOE) with the society’s inaugural Social Responsibility in the Nuclear Community Award for their courage and leadership in pioneering the integration of public schools in the southeast United States.

ANS is honoring Civil Rights-era students and the U.S. Dept. of Energy with inaugural award for integrating first public schools in the southeast U.S.

The American Nuclear Society (ANS) is honoring 85 former students from Tennessee, known as the Scarboro-Oak Ridge, TN 85, and the U.S. Department of Energy (DOE) with the society’s inaugural Social Responsibility in the Nuclear Community Award for their roles in integrating in 1955 the first public schools in the southeastern United States. The award will be presented at the upcoming 2021 ANS Winter Meeting and Technology Expo (Nov. 30 – Dec. 3) being held in Washington, D.C.

ORNL’s Benjamin Manard places a swipe on the extraction stage of Advion’s Plate Express, a microextraction tool that has been paired with a mass spectrometer. (Photo: Carlos Jones/ORNL, DOE)

International nuclear safeguards verification relies on a precise count of isotope particles collected on swipes during International Atomic Energy Agency inspections of nuclear facilities and isolated through a series of lengthy chemical separations that can take about 30 days to complete. On October 15, Oak Ridge National Laboratory—a member of the IAEA’s Network of Analytical Laboratories (NWAL)—announced that analytical chemists at the site have developed a faster way to measure isotopic ratios of uranium and plutonium collected on swipes, which could help IAEA analysts detect the presence of undeclared nuclear activities or material.

A view of the final remaining hot cell at the former Radioisotope Development Laboratory at Oak Ridge National Laboratory as it is prepared for demolition. (Photo: DOE)

Using a specialized radiation detector, Department of Energy cleanup contractor UCOR is characterizing a hot cell at Oak Ridge National Laboratory in preparation for its demolition. The detector overlays a radiation-intensity color-map on a picture of the environment and identifies gamma-emitting nuclides and their locations.

Sandia's Brad Beeny (left) and Larry Humphries examine remnants from a series of lower head failure experiments. Results from these and other experiments are used to inform nuclear accident modeling computer code. (Photo: Randy Montoya)

Researchers at Sandia National Laboratories have been expanding MELCOR—the severe accident modeling computer code used by the Nuclear Regulatory Commission to evaluate the safety of light water reactors—to study the small modular reactors and non-light-water advanced reactors that are under development. An article published in Sandia Lab News on August 27 describes in detail how MELCOR is being expanded to work with different reactor geometries, fuel types, and coolant systems.

The EBR-II sodium fast reactor at Idaho National Laboratory began operations in 1964 and generated electricity for decades. Soon it will serve as a National Reactor Innovation Center test bed for future advanced reactor demonstrations. (Source: ANL)

At the box office or streaming at home, it’s fear, not truth, that sells. The laws of physics are swept aside, apocalypse is inevitable, and superpowered heroes wait until the last possible second to save the universe. It can make for great entertainment, but in the real world we need to stick with science over science fiction and be wowed by engineering, not special effects.

The truth is, science and innovation are incredible in their own right. From communications and machine learning to space travel and medical advances, technology is evolving in hyperdrive to solve real problems. With climate change and global warming here on earth, we don’t have to go looking for trouble in a galaxy far, far away.

Chemist Kevin Gaddis has adapted components of a high-pressure ion chromatography system to withstand the extreme conditions of a hot cell. (Photo: ORNL/Carlos Jones)

An Oak Ridge National Laboratory researcher has built a device that can speed up the separation of the medical radioisotope actinium-225 from irradiated thorium targets and withstand the high-radiation environment of a hot cell. In July, ORNL announced that Kevin Gaddis, a chemistry technician at the lab, had built and tested a prototype and was working to secure a patent for a device that cut separations time by 75 percent.

Irradiated lead test rods are delivered to Oak Ridge National Laboratory for examination. (Photo: ORNL)

Several lead test rods of Westinghouse’s EnCore accident tolerant fuel recently arrived at Oak Ridge National Laboratory for post-irradiation examination over the next year in support of the Nuclear Regulatory Commission’s licensing process. The rods were installed in 2019 in Exelon’s Byron-2, a 1,158-MWe pressurized water reactor, and were removed in fall 2020 and prepared for shipment to ORNL.