An illustration of a potential mobile microreactor site at Test Pad D in INL’s Critical Infrastructure Test Range Complex for the grid operation phase of Project Pele. (Image: DOD)

The U.S. Department of Defense (DOD) is looking to reduce its reliance on local electric grids and diesel-fueled generators at military installations. Project Pele is designed to demonstrate the technical and safety features of mobile microreactors capable of generating up to 5 MWe.

The interior of the Submarine 1st Generation Westinghouse prototype, located at the Naval Reactors Facility on the INL site, circa mid-1950s. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced on February 10 that it is set to deactivate and demolish the prototype for the reactor used for the USS Nautilus, the world’s first operational nuclear-powered submarine and the first submarine to complete a submerged transit of the North Pole.

The MARVEL microreactor prototype in the INL machine shop. (Photo: DOE)

A full-scale, electrically heated prototype for the Department of Energy’s Microreactor Applications Research Validation and Evaluation (MARVEL) project was fabricated in just nine months, according to an article published by Idaho National Laboratory on January 31. The article explains in part how a team from the lab’s machine shop created the prototype.

INL scientists Matt Snow and Jessica Ward hold a natural vanadium solution that will be separated into the cancer-treating isotope scandium-47. (Photo: INL)

Idaho National Laboratory researchers have, for the first time, used a novel technique using high-energy photons to produce scandium-47 from the element vanadium. The project is a collaboration with Jon Stoner and John Longley from Idaho State University’s Idaho Accelerator Center and Tara Mastren from the University of Utah. The results are published in the journal Applied Radiation and Isotopes.

October 8, 2021, 3:31PMUpdated December 31, 2021, 4:16PMNuclear NewsJoseph Campbell; Photos by Joseph Campbell and Peter Ritchie, INL The first of three phases of the Advanced Test Reactor’s sixth core overhaul culminated with the removal of the 31-ton stainless steel vessel top head on July 1, for the first time since 2004. The vessel and top head underwent extensive inspection, laser scanning, and upgrade as part of the overhaul. (Photo: JC)

As 2021 closes, Nuclear News is taking a look back at some of the feature articles published each month in the magazine. The October issue focused on plant maintenance and outage management with multiple articles looking at efficient ways to deal with plant maintenance. The article below looks at the herculean effort by INL to lead a full overhaul of the Advanced Test Reactor--a task that happens about every 10 years.

Out of the frenzy of nuclear technology and engineering development at the height of the Atomic Age, a few designs stand out above the rest—designs so innovative that they would not be surpassed for years, or even decades. An example of this unsurpassed design brilliance exists in the form of Idaho National Laboratory’s Advanced Test Reactor.

“ATR is really a beautiful machine,” said Sean O’Kelly, associate lab director for the ATR Complex. “The elegant cloverleaf core and control systems were a stroke of genius that solved just about every key problem of test reactor design. The designers’ solutions to those problems give us a testing capacity and flexibility that have yet to be matched.”

Coated uranium fuel kernels, as viewed through a glovebox. (Photo: BWXT)

Nuclear thermal propulsion (NTP) is one technology that could propel a spacecraft to Mars and back, using thermal energy from a reactor to heat an onboard hydrogen propellant. While NTP is not a new concept, fuels and reactor concepts that can withstand the extremely high temperatures and corrosive conditions experienced in the engine during spaceflight are being designed now.

BWX Technologies announced on December 13 that it has delivered coated reactor fuels to NASA for testing in support of the Space Technology Mission Directorate’s NTP project. BWXT is developing two fuel forms that could support a reactor ground demonstration by the late 2020s, as well as a third, more advanced and energy-dense fuel for potential future evaluation. BWXT has produced a videoof workers processing fuel kernels in a glovebox.

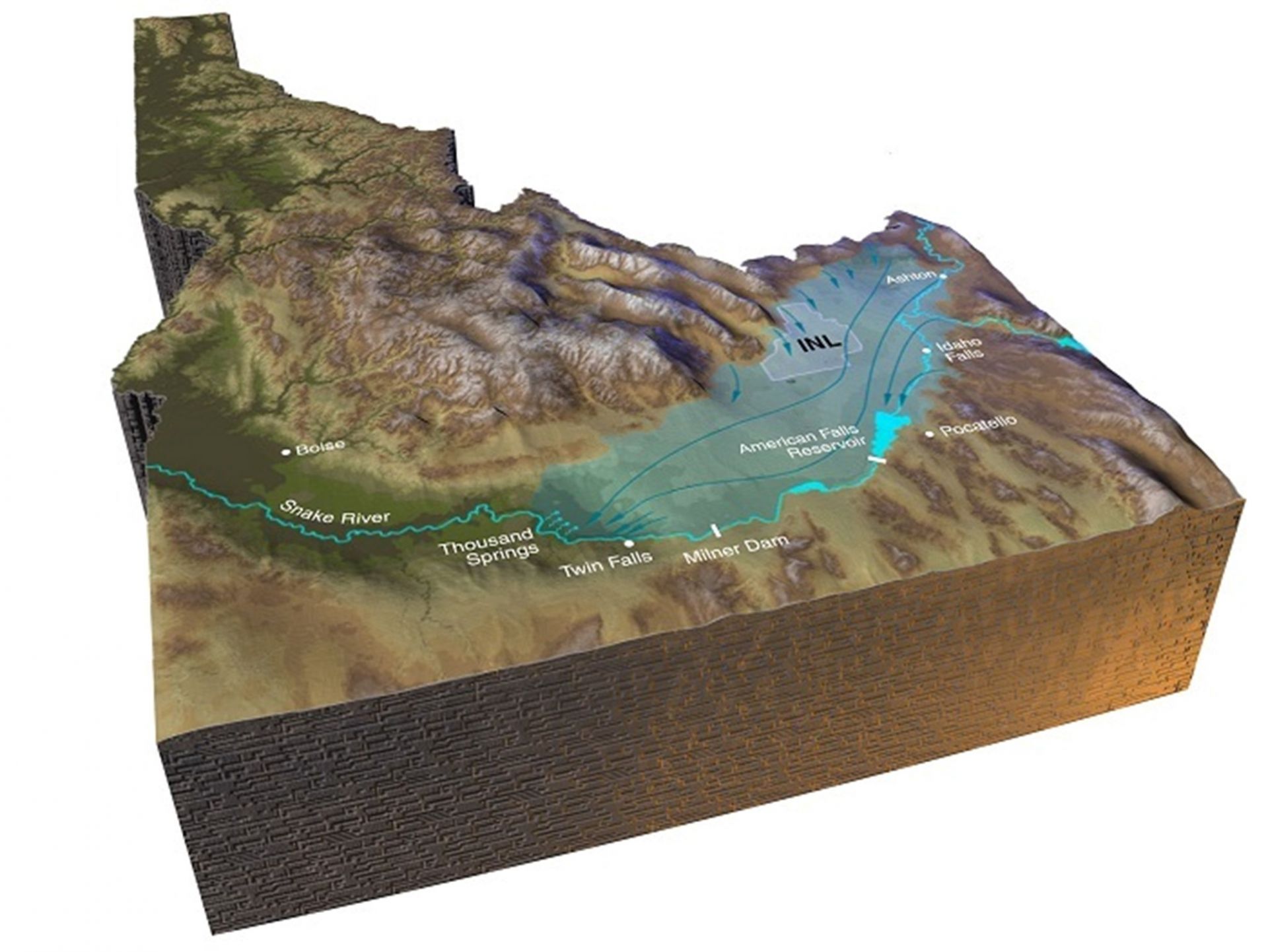

The underlying Snake River Plain Aquifer is considerably safer today following three decades of cleanup activities at the DOE’s Idaho National Laboratory Site. (Graphic: DOE)

When the Department of Energy, the state of Idaho, and the Environmental Protection Agency signed a federal facility agreement and consent order in December 1991, the agencies outlined a plan to investigate and clean up, if necessary, more than 500 individual waste areas within the 890-square-mile Idaho National Laboratory (INL) Site, which was established in 1949 to design, build, and test nuclear reactors.

Artist's rendition of the Versatile Test Reactor. (Source: DOE)