Concept art of the planned Gadsden, Ala., MMR assembly plant. (Image: Ultra Safe Nuclear)

Ultra Safe Nuclear (USNC) announced on June 21 that it has selected the city of Gadsden, Ala., to host a $232 million MMR assembly plant. Modules for the company’s high-temperature, gas-cooled and TRISO-fueled microreactor, dubbed the Micro-Modular Reactor (MMR), would be manufactured, assembled, and tested at the “highly automated facility” once it is in operation.

Centrus’s HALEU demonstration cascade. (Photo: Centrus Energy)

Centrus Energy announced yesterday that it has received Nuclear Regulatory Commission approval to introduce uranium hexafluoride into its 16-machine centrifuge cascade in Piketon, Ohio, following operational readiness reviews by the NRC. Centrus says it “remains on track to begin production of high-assay low-enriched uranium (HALEU) by the end of 2023.” The announcement follows a series of inspections at the American Centrifuge site in April 2023.

A Framatome operator fabricates U-Mo foils at CERCA. (Photo: Framatome)

Framatome is prepared to manufacture a novel molybdenum-uranium (U-Mo) fuel to extend the life and safe operation of the Forschungsreaktor München II (FRM II) research reactor in Germany. A new fuel supply—one that uses uranium enriched to less than 20 percent U-235—means the FRM II can continue to supply neutrons to industry and the scientific community. The fuel is “Europe’s low-enriched fuel with the highest density ever realized for research reactor operations,” according to Framatome’s April 27 announcement.

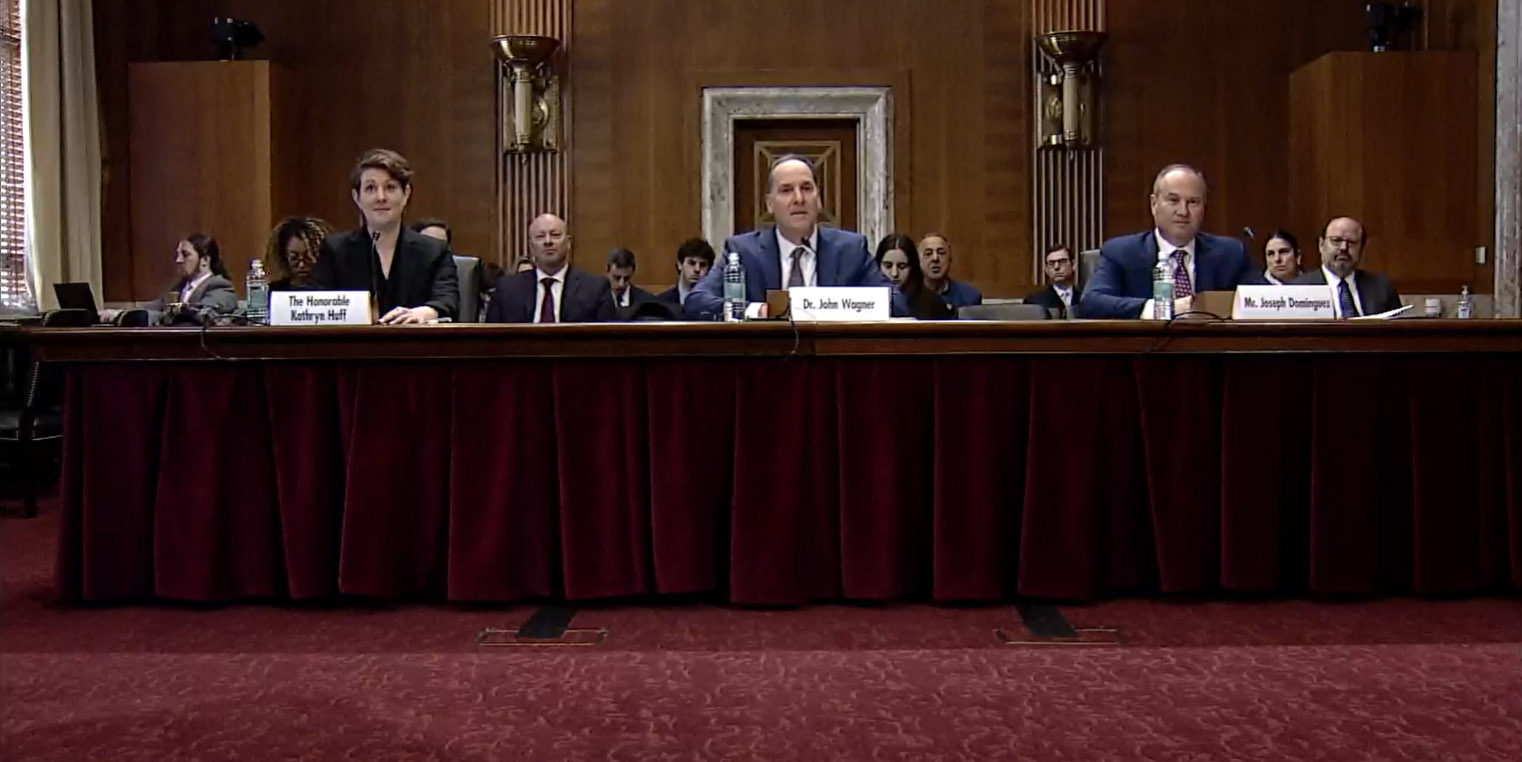

March 14, 2023, 9:39AMEdited March 14, 2023, 9:38AMNuclear News In this screenshot from a video recording of the hearing, Huff, Wagner, and Dominguez answer a series of questions from Sen. Manchin

“Right now, our country is deficient in nearly every aspect of the fuel cycle. This must change and it must change quickly,” said Sen. Joe Manchin (D., W.V.), chairman of the Senate Committee on Energy and Natural Resources (ENR), as he opened a Full Committee Hearing to Examine the Nuclear Fuel Cycle on March 9. “Whether it is uranium mining, milling, conversion, enrichment, nuclear fuel fabrication, power generation, or nuclear waste storage and disposal, there is much work to be done, starting with conversion and enrichment. Simply put, Russia dominates the global market, representing nearly half of the international capacity for both processes.”

Mock-up of four-lobed helical fuel rods. (Photo: Lightbridge)

Lightbridge Corporation, which is continuing to work closely with national laboratories on the manufacture and testing of its metallic fuel rod designs for light water reactors, just announced the results of an investigation on the casting process for molten uranium and zirconium with Pacific Northwest National Laboratory under the Department of Energy’s Gateway for Accelerated Innovation in Nuclear (GAIN) program.

Energy Fuels’ White Mesa Mill in southeastern Utah is the only operating conventional uranium mill in the United States. (Photo: Energy Fuels)

The bipartisan Nuclear Fuel Security Act (NFSA), introduced in the Senate last week, would authorize the Department of Energy to establish a Nuclear Fuel Security Program to “ensure a disruption in Russian uranium supply would not impact the development of advanced reactors or the operation of the United States’ light water reactor fleet.” The bill was introduced by Sen. Joe Manchin (D., W.V.), chairman of the Senate Energy and Natural Resources (ENR) Committee; Sen. John Barrasso (R., Wyo.), ranking member of the Senate ENR committee; and Sen. Jim Risch (R., Idaho).

A view of the completed demo cascade. (Photo: Centrus)

Centrus Energy announced February 9 that it has finished assembling a cascade of uranium enrichment centrifuges and most of the associated support systems ahead of its contracted demonstration of high-assay low-enriched uranium (HALEU) production by the end of 2023. When the 16-machine cascade begins operating inside the Piketon, Ohio, American Centrifuge Plant, which has room for 11,520 machines, it will be the first new U.S.-technology based enrichment plant to begin production in 70 years.

U.S. secretary of energy Jennifer Granholm and Japan’s minister of economy, trade, and industry Yasutoshi Nishimura lead energy discussions on January 9 in Washington, D.C. (Photo: DOE)

Researchers at Idaho National Laboratory have completed initial testing on a newly developed fuel test capsule that is expected to provide crucial performance data for sodium-cooled fast reactors. The Department of Energy announced on January 12 that the series of fuel testing experiments being carried out now at INL’s Transient Reactor Test Facility (TREAT) was developed through a joint project between the United States and Japan.

Artist’s rendering of the proposed TRISO-X World Headquarters and Commercial Fuel Facility at the Horizon Center Industrial Park in Oak Ridge, Tenn. (Image: X-energy)

The Nuclear Regulatory Commission has accepted an application from X-energy's fuel subsidiary, TRISO-X LLC, for a proposed TRISO-X Fuel Fabrication Facility (TF3) in Oak Ridge, Tenn., X-energy announced last week. A 30-month review schedule has been developed by the NRC that would be completed by June 2025, assuming TRISO-X provides sufficient responses to expected requests for additional information (RAIs) within 30 to 60 days of their issuance. On December 16, the NRC announced that it would seek public input on the scope of its environmental review and environmental impact statement for the application and published a notice in the Federal Register.

These gas centrifuges operated in the Piketon facility from 2013 to 2016 as part of a 120-machine low-enriched uranium demonstration cascade. (Photo: Centrus Energy)

Centrus Energy confirmed on December 1 that its wholly owned subsidiary American Centrifuge Operating signed a contract with the Department of Energy, which was first announced on November 10, to complete and operate a demo-scale high-assay low-enriched uranium (HALEU) gaseous centrifuge cascade.

From left: Christina Leggett (Booz Allen Hamilton), Morris Hassler (IB3 Global Solutions), Everett Redmond (Oklo), Andy Griffith (DOE-NE), Ben Jordan (Centrus), Stephen Long (GLE), and Magnus Mori (Urenco).

Whether commercial demand for high-assay low-enriched uranium (HALEU) fuel ultimately falls at the high or low end of divergent forecasts, one thing is certain: the United States is not ready to meet demand, because it currently has no domestic HALEU enrichment capacity. But conversations happening now could help build the commercial HALEU enrichment infrastructure needed to support advanced reactor deployments. At the 2022 American Nuclear Society Winter Meeting, representatives from three potential HALEU enrichers, the government, and industry met to discuss their timelines and challenges during “Got Fuel? Progress Toward Establishing a Domestic US HALEU Supply,” a November 15 executive session cosponsored by the Nuclear Nonproliferation Policy Division and the Fuel Cycle and Waste Management Division.

Coles Hill property location. (Image: Consolidated Uranium)

Consolidated Uranium plans to acquire Virginia Energy Resources, which owns Virginia Uranium and the Coles Hill Uranium Project, an undeveloped uranium deposit that sits under about 3,000 acres of land in south central Virginia. The state’s General Assembly has maintained a moratorium on uranium mining since 1982 that was upheld in the courts as recently as 2020, but Consolidated Uranium sees reason for “confidence that the moratorium on developing uranium projects in the state may ultimately be overcome,” and appears content to settle in for a wait.

Centrifuge casings arrive in Piketon, Ohio. (Photo: Centrus Energy)

The Department of Energy announced a cost-shared award on November 10 valued at about $150 million for American Centrifuge Operating, a subsidiary of Centrus Energy, to complete the high-assay low-enriched uranium (HALEU) demonstration project it began in 2019. After delays that Centrus attributes in part to the COVID-19 pandemic, the company now has until the end of 2023 to produce the first 20 kilograms of HALEU enriched to 19.75 percent U-235 from the 16-centrifuge cascade it has installed in a DOE-owned Piketon, Ohio, facility—the only U.S. facility currently licensed to produce HALEU.

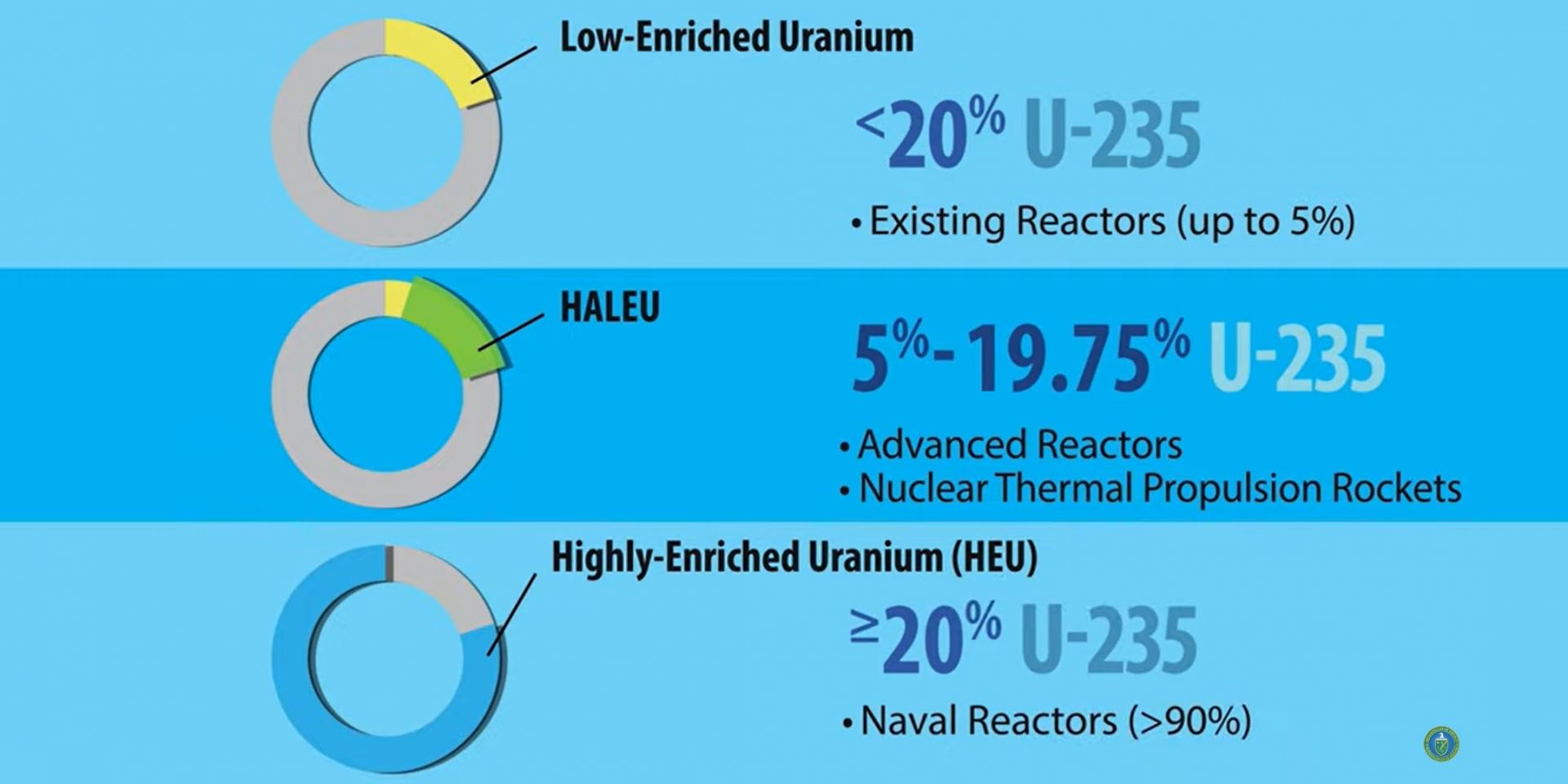

An image from the video “What is High-Assay Low-Enriched Uranium (HALEU)?” released by the DOE in April 2020. (Source: DOE)

Another piece of the plan for meeting the urgent need for high-assay low-enriched uranium (HALEU) to fuel advanced reactor deployments fell into place when the Department of Energy held an Industry Day on October 14. Attendees were asked how soon they could deliver 25 metric tons per year of HALEU enriched in the United States from newly mined uranium. Offtake contracts for six or more years of HALEU production at that rate could be used to stock a DOE-owned HALEU bank to “support [HALEU] availability for civilian domestic research, development, demonstration, and commercial use.”

Government officials and representatives of X-energy and its TRISO-X subsidiary at the October 13 groundbreaking. (Photo: X-energy)

Leaders of X-energy and its TRISO-X subsidiary gathered on October 13 to break ground at the site of what X-energy bills as “North America’s first commercial-scale advanced nuclear fuel facility” in Oak Ridge, Tenn. X-energy expects the TRISO-X Fuel Fabrication Facility (TF3) to create more than 400 jobs and to be commissioned and operational by 2025.

Terrani, Huff, and Fleischmann had the honor of cutting the ribbon to celebrate the opening of the Pilot Fuel Manufacturing facility. (Photo: USNC)

Ultra Safe Nuclear Corporation (USNC) celebrated the opening of its Pilot Fuel Manufacturing (PFM) facility in Oak Ridge, Tenn., on August 18 with a ribbon-cutting ceremony and tour attended by assistant secretary for nuclear energy Kathryn Huff, Tennessee lieutenant governor Randy McNally, U.S. Rep. Chuck Fleischmann (R.), representatives from the offices of Sens. Marsha Blackburn (R.) and Bill Hagerty (R.), and other distinguished guests. The next day, radiological operations began at the privately funded facility, which was designed and built in less than twelve months within an existing industrial building purchased by USNC in 2021.