A screenshot from the Local 12 report. (Image: WKRC/Sinclair)

In May 2019, Zahn’s Corner Middle School in Pike County, Ohio, located within four miles of the former Portsmouth Gaseous Diffusion Plant (PORTS), was closed after local officials reported enriched uranium and transuranic radionuclides were detected inside the school and at outside air monitors.

Now, Cincinnati’s WKRC Local 12, a news affiliate of Sinclair Broadcast Group, is reporting that a private house in Lucasville, Ohio, 10 miles from the PORTS site, has been contaminated with enriched uranium.

Participating in the forum were (from left) John Hopkins (NuScale Power), Renaud Crassous (EDF), Daniel Poneman (Centrus Energy), Adriana Cristina Serquis (CNEA), and Boris Schucht (Urenco).

The nuclear industry leaders assembled in Washington, D.C., last week to discuss small modular reactor supply chains agreed that lost generation capacity from the expected retirement of hundreds or thousands of coal power plants over the next decade—a cliff, in one panelist’s words—represents an opportunity that developers of SMRs and advanced reactors are competing to meet.

“I think in total 80 projects are ongoing,” said Boris Schucht, panel moderator and chief executive officer of Urenco Group, as he opened the forum. “Of course not all of them will win, and we will discuss today what is needed so that they can be successful.”

INL’s Materials and Fuels Complex. (Photo: INL)

The Department of Energy announced $150 million in Inflation Reduction Act funding on October 25 for infrastructure improvements at Idaho National Laboratory. According to the DOE, the funding will support nearly a dozen projects at INL’s Advanced Test Reactor (ATR) and Materials Fuels Complex (MFC), both of which have operated for more than 50 years. The investments in existing infrastructure assets mean support for nuclear energy research and development, including fuel testing, bolstering the near-term supply of high-assay low-enriched uranium (HALEU), and reactor demonstrations.

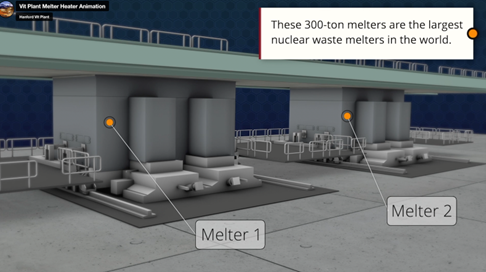

Workers install one of 18 startup heaters into Melter 1 of Hanford’s Low-Activity Waste Facility. (Photo: Bechtel National)

Heating of the first waste vitrification melter at the Department of Energy’s Hanford Site was paused after operators identified an “abnormal condition with the startup heater power supplies,” the DOE’s Office of River Protection (ORP) said. Heat-up of the 300-ton melter, which will be used to vitrify Hanford’s low-level radioactive tank waste, was initiated on October 8.

Secretary Granholm, center, leads breaking the ground for the SIPRC at ORNL, along with (from left) ORNL site manager Johnny Moore, ORNL director Thomas Zacharia; DOE undersecretary for science and innovation Geraldine Richmond; and DOE Office of Science director Asmeret Asefaw Berhe. (Photo: Genevieve Martin/ORNL/DOE)

The Department of Energy held a groundbreaking ceremony on October 24 for the Stable Isotope Production and Research Center (SIPRC) at Oak Ridge National Laboratory in Tennessee. The center is being built to expand the nation’s capability to enrich stable isotopes for medical, industrial, and research applications.

Natrium Fuel Facility groundbreaking. (Photo: GNF-A)

Global Nuclear Fuel–Americas (GNF-A) and TerraPower announced their plans to build a Natrium fuel fabrication facility next to GNF-A’s existing fuel plant near Wilmington, N.C, on October 21. While more than 50 years of fuel fabrication at the site have supported the boiling water reactor designs of GE (GNF-A’s majority owner) and GE Hitachi Nuclear Energy (GEH), the Natrium Fuel Facility will produce metallic high-assay low-enriched uranium (HALEU) fuel for the sodium fast reactor—Natrium—that TerraPower is developing with GEH.

A rendering of the six-module Carbon Free Power Project planned for construction in Idaho. (Image: NuScale)

NuScale Power announced October 20 that the Nuclear Regulatory Commission’s Advisory Committee on Reactor Safeguards (ACRS) issued a letter the previous day agreeing with NRC staff’s approval of NuScale’s methodology for determining the plume exposure pathway emergency planning zone (EPZ). As approved, the methodology would permit a smaller EPZ—dependent on site-specific conditions, including seismic hazards—that provides the same level of protection to the public as the 10-mile radius EPZs used for existing U.S. nuclear power plants.

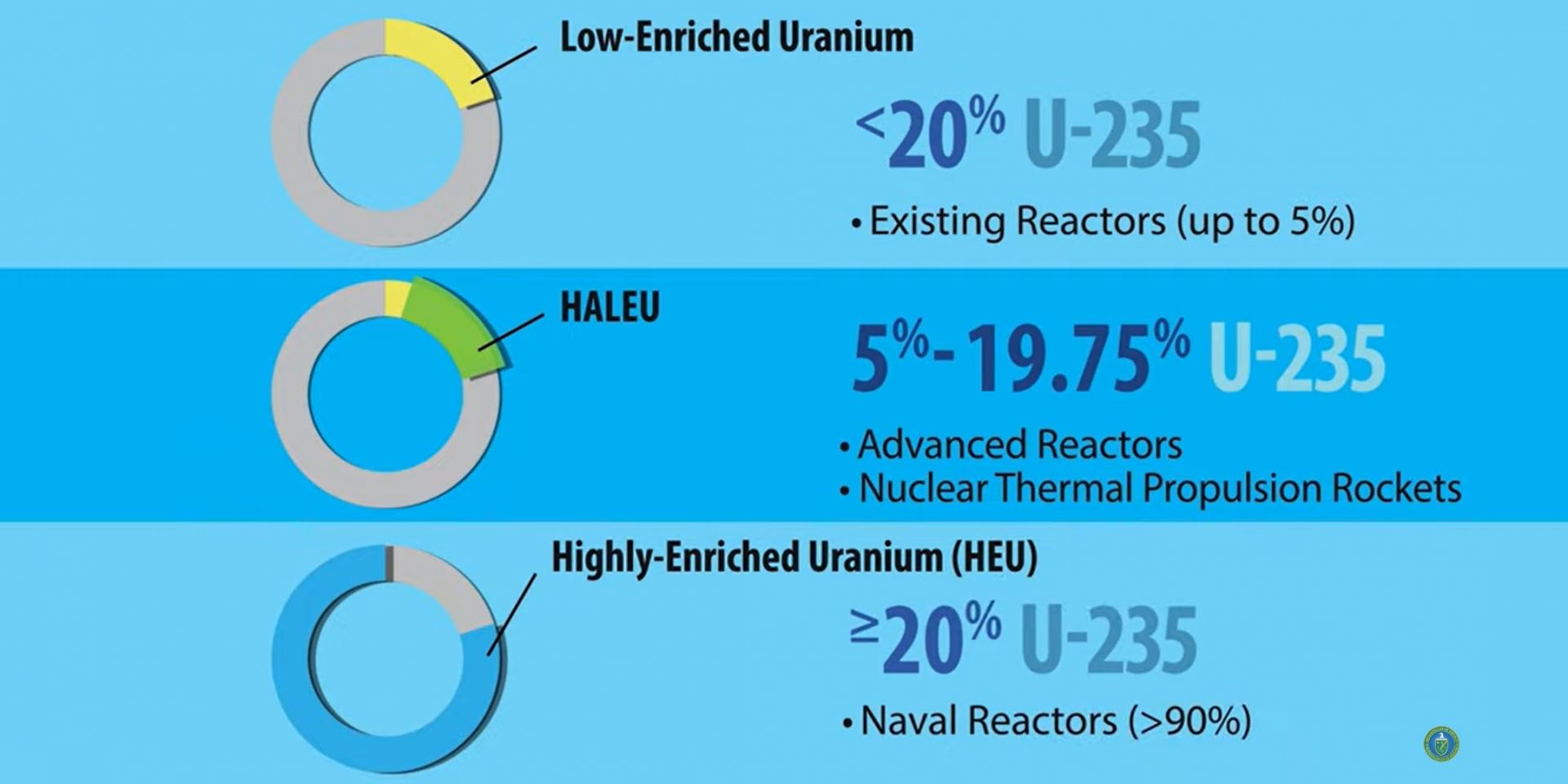

An image from the video “What is High-Assay Low-Enriched Uranium (HALEU)?” released by the DOE in April 2020. (Source: DOE)

Another piece of the plan for meeting the urgent need for high-assay low-enriched uranium (HALEU) to fuel advanced reactor deployments fell into place when the Department of Energy held an Industry Day on October 14. Attendees were asked how soon they could deliver 25 metric tons per year of HALEU enriched in the United States from newly mined uranium. Offtake contracts for six or more years of HALEU production at that rate could be used to stock a DOE-owned HALEU bank to “support [HALEU] availability for civilian domestic research, development, demonstration, and commercial use.”

The Integrated Effects Test at TerraPower’s laboratory in Everett, Wash. (Photo: Southern Company/TerraPower)

“The world's largest chloride salt system developed by the nuclear sector” is now ready for operation in TerraPower’s Everett, Wash., laboratories. Southern Company, which is working with TerraPower through its subsidiary Southern Company Services to develop molten chloride reactor technology, announced on October 18 that the Integrated Effects Test (IET) was complete. The multiloop, nonnuclear test infrastructure follows years of separate effects testing using isolated test loops, and it was built to support the operation of the Molten Chloride Reactor Experiment (MCRE) at Idaho National Laboratory that the companies expect will, in turn, support a demonstration-scale Molten Chloride Fast Reactor (MCFR).

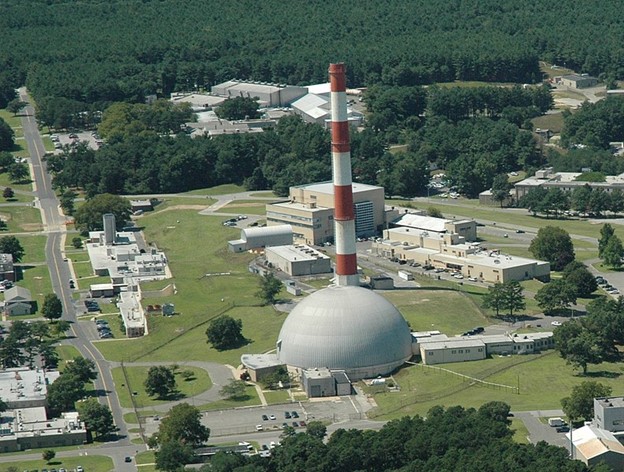

Then energy secretary Bill Richardson decided to permanently shut down the HFBR in November 1999. (Photo: DOE)

“Why did a tiny leak bring down a hugely successful research reactor 25 years ago?”

That’s how Robert P. Crease, an academic who writes a regular column for Physics World, introduces The Leak: Politics, Activists, and Loss of Trust at Brookhaven National Laboratory, a book he wrote with former interim BNL director Peter D. Bond that was published this month by MIT Press.

“Were this story fiction, its characters, plot twists and ironies would be entertaining,” Crease writes in his October 5 Physics World post about the book. “But because it’s fact, it’s a tragicomedy.”

Government officials and representatives of X-energy and its TRISO-X subsidiary at the October 13 groundbreaking. (Photo: X-energy)

Leaders of X-energy and its TRISO-X subsidiary gathered on October 13 to break ground at the site of what X-energy bills as “North America’s first commercial-scale advanced nuclear fuel facility” in Oak Ridge, Tenn. X-energy expects the TRISO-X Fuel Fabrication Facility (TF3) to create more than 400 jobs and to be commissioned and operational by 2025.

A rendering of the Versatile Test Reactor site. Image: INL

LA GRANGE PARK, Illinois – Idaho National Laboratory’s crucial Versatile Test Reactor (VTR) project is the focus of a newly released special issue of Nuclear Science and Engineering, the first and oldest peer-reviewed journal in its field. This special issue of the American Nuclear Society’s flagship journal presents a current snapshot of the nuclear innovation project at INL, which is being developed in partnership among six national labs and a host of industry and university partners.

An aerial view of ORNL’s main campus. (Photo: ORNL)

The Gateway for Accelerated Innovation in Nuclear (GAIN) announced the three recipients of its fourth and final round of 2022 vouchers on October 10. The vouchers were awarded to Curio Solutions, which is developing a spent fuel recycling process, and to two companies that are separately investigating advanced reactor siting—Elementl Power and the Tennessee Valley Authority (TVA). The funds for each award will go directly to Oak Ridge National Laboratory.

A screenshot from a 3D animation showing the heat-up of Hanford’s melters. (Image: DOE)

Crews at the Department of Energy’s Hanford Site, near Richland, Wash., have begun heating up the first of two 300-ton melters that will be used to vitrify mixed low-level radioactive and chemical tank waste. According to the DOE’s Office of Environmental Management (EM), initiating and completing the heating of the melter is a critical step to commissioning Hanford’s Waste Treatment and Immobilization Plant (WTP), which will treat and stabilize the site’s 56 million gallons of tank waste by immobilizing it in glass through the vitrification process.