Construction crews finish work on large ductwork for WIPP’s new SSCVS facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management announced that it has completed construction of the new large-scale ventilation system at its Waste Isolation Pilot Plant in New Mexico.

All major concrete placements have been completed on Saltstone Disposal Unit 10, the latest megavolume disposal unit being built at the Savannah River Site. This aerial view shows the final roof section being installed on the unit. (Photo: DOE-EM)

With the placement of 25 wall sections, 208 support columns, and 7 roof sections, work crews have completed all major concrete placements for the megavolume Saltstone Disposal Unit (SDU) 10 at the Savannah River Site in South Carolina, according to the Department of Energy’s Office of Environmental Management.

Stephanie Doll of WRPS poses next to the metal patch applied during the demonstration. (Photo: DOE)

The Department of Energy’s Office of Environmental Management and its contractor Washington River Protection Solutions (WRPS) recently demonstrated the use of cold spray technology as a means of refurbishing double-shell waste tanks at the Hanford Site in Washington state. The tanks store liquid radioactive and chemical waste that was created during Hanford’s plutonium production era.

The Atlas railcar carries a test load simulating a shipment of spent nuclear fuel. (Photo: DOE)

The Department of Energy’s Office of Nuclear Energy announced last week that the Association of American Railroads has certified its Atlas railcar system to operate on all major freight railroads in the United States.

Watch a video of the Atlas railcar development here.

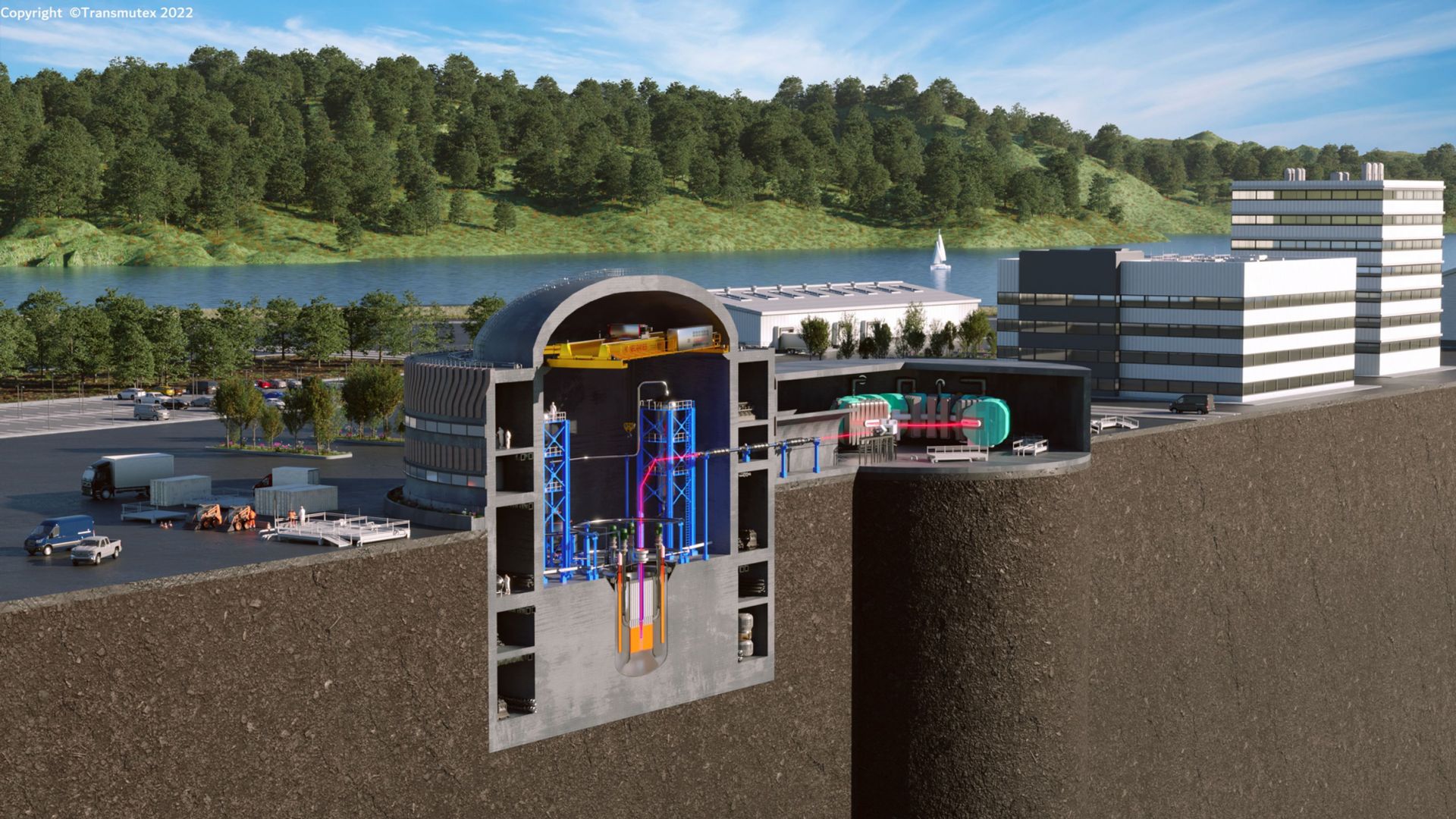

Transmutex’s transmutation reactor. (Image: Transmutex)

Switzerland’s national cooperative for the disposal of radioactive waste, Nagra, is distancing itself from recent reports regarding the work of the Geneva-based engineering start-up Transmutex, which claims to have developed a new technology for the transmutation of radioactive waste.

The Savannah River Site’s shielded canister transporter. (Photo: DOE)

The large vehicle used to transport highly radioactive canisters at the Department of Energy’s Savannah River Site has completed a pit stop to ensure the continued movement of the site’s radioactive liquid waste work.

Lourdes Legaspi, engineering automation supervisor (center) and her team are designing pipe and equipment components for the Hanford Site’s partially completed HLW Facility. A collaboration between the DOE and Bechtel National set a foundation for requirements engineers will follow in continuing the design of the facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management announced that its Office of River Protection (ORP) recently created a plan with contractor Bechtel National for completing the High-Level Waste Facility at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

A 125-foot-tall exhaust stack towers over the Safety Significant Confinement Ventilation System’s filter building at the Waste Isolation Pilot Plant. (Photo: DOE)

The Defense Nuclear Facilities Safety Board (DNFSB), an independent government organization responsible for overseeing public health and safety issues at Department of Energy defense nuclear facilities, has alerted the DOE because of safety concerns it has regarding the use of continuous air monitors (CAM) at the Waste Isolation Pilot Plant in New Mexico.

Part of WIPP’s new Safety Significant Confinement Ventilation System (SSCVS), the CAM system is intended to detect a radiological release in the repository and automatically close vent dampers to prevent the escape of radioactive particles to the outside environment. The SSCVS, which began commissioning in November 2023, is intended to increase airflow to the underground to allow for simultaneous underground waste emplacement, mining, and ground control work.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

Researchers at the Department of Energy’s Argonne National Laboratory are investigating the details of plutonium chemistry with the goal of aiding the cleanup of the Hanford Site in Washington state. For more than 40 years, reactors located at Hanford produced plutonium for America’s defense program, resulting in millions of gallons of liquid radioactive and chemical waste.

An aerial view of the Hanford Site’s 200 Area and the Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: DOE)

The U.S. Department of Energy, Washington State Department of Ecology, and U.S. Environmental Protection Agency have reached an agreement on revised plans for managing millions of gallons of radioactive and chemical liquid waste stored in 177 underground tanks at the Hanford Site near Richland, Wash.

Data from Fukushima ALPS-treated water discharge. (Image: IAEA)

An International Atomic Energy Agency task force has confirmed that the discharge of treated water from Japan's Fukushima Daiichi nuclear power plant is progressing in accordance with the plan approved by Japan’s Nuclear Regulation Authority.

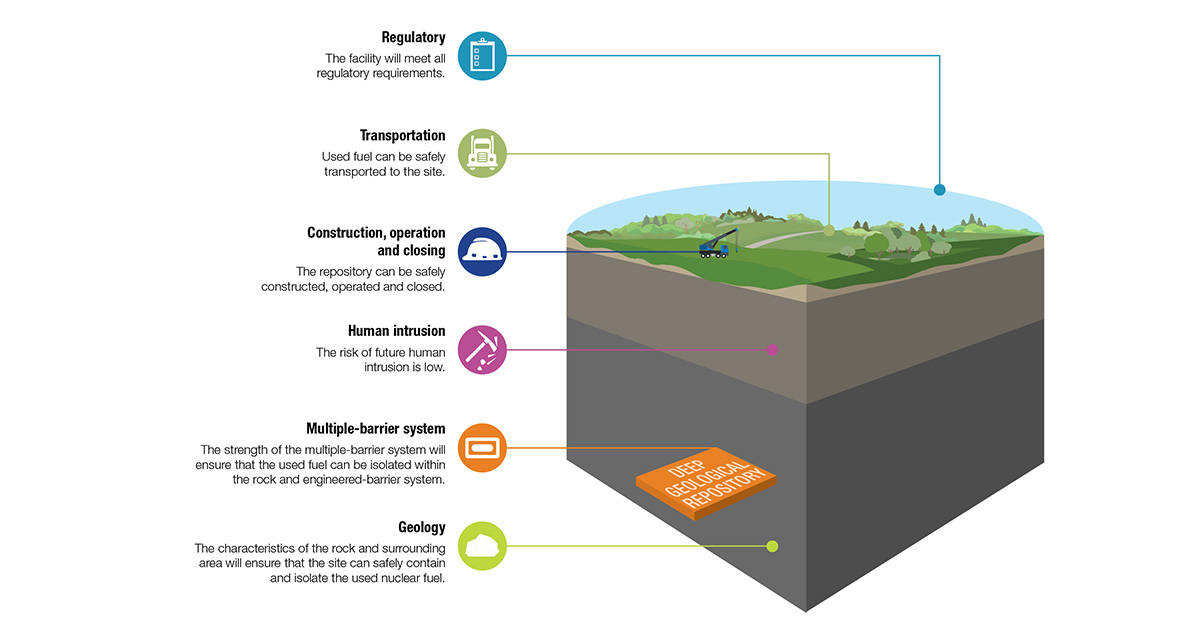

An illustration of a planned deep geologic repository for Canada’s spent nuclear fuel. (Image: NWMO)

Canada’s Nuclear Waste Management Organization, a not-for-profit organization responsible for the long-term management of the country’s intermediate- and high-level radioactive waste, is set to select a site for a deep geologic repository by the end of the year.

A view of the Waste Isolation Pilot Plant in New Mexico. (Photo: DOE)

Harrison Western Shaft Sinkers (HWSS), the company drilling a new utility shaft at the Department of Energy’s Waste Isolation Pilot Plant in New Mexico, has retained a safety culture expert following a near-miss accident in the shaft late last year. The safety expert will conduct monthly facilitated discussions with crews working on the shaft to reinforce expectations for identifying concerns regarding unsafe circumstances, according to a recent report by the Defense Nuclear Facilities Safety Board (DNFSB).

SDU 9 is the latest megavolume disposal unit completed at SRS. (Photo: DOE)