The first shipment of downblended surplus plutonium from SRS’s K Area leaves SRS. (Photo: DOE)

The Department of Energy’s National Nuclear Security Administration and Office of Environmental Management have completed the first shipment of downblended surplus plutonium transuranic (TRU) material from the K Area at the Savannah River Site in South Carolina to the Waste Isolation Pilot Plant in New Mexico.

The Integrated Waste Treatment Unit at the Idaho National Laboratory Site. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) said that the Integrated Waste Treatment Unit (IWTU), the radioactive liquid waste treatment facility at the Idaho National Laboratory Site, began its final heat-up in December prior to initiating radiological operations, planned for early this year.

IWTU crews were to follow a prescribed incremental process as the facility transitions from simulant to sodium-bearing waste (SBW), according to EM.

A radiological control technician checks radiation readings on waste containers at WIPP. (Photo: WIPP)

The New Mexico Environment Department (NMED) is adding several conditions to the operating permit for the Department of Energy’s Waste Isolation Pilot Plant (WIPP) near Carlsbad, N.M. The permit changes, which would prioritize the disposal of transuranic (TRU) waste generated in the state and limit the repository’s capacity, are contained in a fact sheet the NMED.

A tanker holding 6200 gallons of leachate unloads at a backup load-in station at the Hanford Site’s ETF. (Photo: DOE)

Construction of a backup load-in station has been completed at the Hanford Site’s Effluent Treatment Facility (ETF) in Washington state.

“We broke ground on the backup facility about a year ago,” said Rob Wood, project manager for Washington River Protection Solutions, the Department of Energy’s tank operations contractor at the site. “I am proud of the team for completing this portion of the load-in expansion project and doing it safely. In phase two, expansion of the main load-in station will prepare us for 24/7 operations on the Hanford Site.”

Watch a time-lapse video of the backup load-in station construction here.

Workers walk down a passageway in Panel 8 at the Waste Isolation Pilot Plant in November. (Photo: DOE)

Employees have begun emplacing defense-related transuranic (TRU) waste in Panel 8 of the Waste Isolation Pilot Plant (WIPP) in New Mexico, the Department of Energy’s Office of Environmental Management (EM) announced in November. TRU waste is permanently disposed of at WIPP in rooms mined in a Permian salt bed 2,150 feet below the surface.

Demolition and disposal shifted into high gear this spring at the DOE’s former uranium enrichment plant in Ohio.

In the 1950s, the U.S. Department of Energy constructed the Portsmouth Gaseous Diffusion Plant in rural southern Ohio to enrich uranium, alongside two other federally owned and managed facilities in Oak Ridge, Tenn., and Paducah, Ky. The Cold War-era plant was built as a self-sufficient industrial city with more than 400 buildings and facilities centered around three massive gaseous diffusion process buildings that could enrich the level of the uranium-235 isotope for nuclear fuel in the defense and energy sectors.

The opening session of ICGR-6. (Photo: OECD NEA)

While deep geological repositories (DGRs) are the globally preferred and scientifically proven solution to store high-level radioactive waste, societal challenges remain. Given the long time frames associated with DGR development and implementation, and a rise in global interest in nuclear energy to meet urgent climate mitigation targets, building and maintaining human capacity is now even more of a priority.

A view of Savannah River’s K Area, where employees began downblending plutonium in 2016. (Photo: DOE)

Contractor employees at the Department of Energy’s Savannah River Site in South Carolina recently exceeded their plutonium downblending goal for 2022 ahead of schedule as part of the ongoing activities to remove Pu from the state, the DOE’s Office of Environmental Management (EM) announced.

Workers install one of 18 startup heaters into Melter 1 of Hanford’s Low-Activity Waste Facility. (Photo: Bechtel National)

Heating of the first waste vitrification melter at the Department of Energy’s Hanford Site was paused after operators identified an “abnormal condition with the startup heater power supplies,” the DOE’s Office of River Protection (ORP) said. Heat-up of the 300-ton melter, which will be used to vitrify Hanford’s low-level radioactive tank waste, was initiated on October 8.

The decommissioning of ORNL’s aging research reactors is clearing the stage for future missions at the site.

An aerial photograph of Oak Ridge National Laboratory’s “Reactor Hill,” with, from left to right, reactor buildings 3042, 3005, and 3010. The DOE and its contractors are removing these excess contaminated facilities to eliminate risks and clear land for future research missions. (Photos: UCOR)

The Department of Energy and its environmental cleanup contractor United Cleanup Oak Ridge (UCOR) are poised to meet critical milestones as they continue to move to the next generation of cleanup at Oak Ridge National Laboratory in Tennessee. On ORNL’s main campus, crews on “Reactor Hill”—so named because of the four remaining reactor facilities on that hillside—and at the Experimental Gas-Cooled Reactor (EGCR) just east of the campus continue rigorous schedules as they enter a new phase of progress in the cleanup program.

DRUM program members and others visit mine sites in the Navajo Nation during the spring of 2022. (Photo: DOE-LM)

The Department of Energy’ Office of Legacy Management (LM) will be conducting verification and validation work at abandoned uranium mines in the Navajo Nation of northeastern Arizona during the fall field season, which runs from mid-October to mid-December.

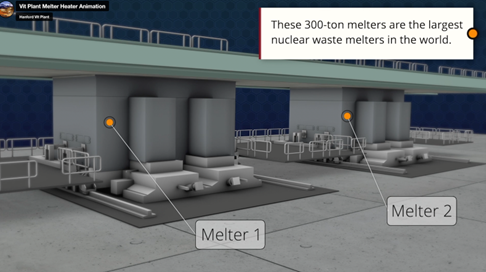

A screenshot from a 3D animation showing the heat-up of Hanford’s melters. (Image: DOE)

Crews at the Department of Energy’s Hanford Site, near Richland, Wash., have begun heating up the first of two 300-ton melters that will be used to vitrify mixed low-level radioactive and chemical tank waste. According to the DOE’s Office of Environmental Management (EM), initiating and completing the heating of the melter is a critical step to commissioning Hanford’s Waste Treatment and Immobilization Plant (WTP), which will treat and stabilize the site’s 56 million gallons of tank waste by immobilizing it in glass through the vitrification process.