Spent fuel in dry storage at the decommissioned Zion site in Illinois awaits a permanent home. (Photo: EnergySolutions)

The deadline for submitting comments on the Department of Energy’s request for information on using a consent-based approach to siting federal facilities for the interim storage of spent nuclear fuel is Friday, March 4.

Spent nuclear fuel handlers move the last ATR fuel to an awaiting cask in the CPP-666 basin. (Photo: DOE)

The last spent nuclear fuel elements from Idaho National Laboratory’s Advanced Test Reactor (ATR) have been retrieved from a water-filled storage basin and transferred to a nearby dry-storage facility in accordance with a 1995 agreement with the State of Idaho, the Department of Energy’s Office of Environmental Management (EM) announced this week.

A screen shot of a YouTube video of the DOE’s U-233 Initial Processing Campaign at Oak Ridge National Laboratory.

Isotek, the Department of Energy contractor responsible for overseeing the inventory of uranium-233 at Oak Ridge National Laboratory and preparing it for removal from the site, said it plans to resume preparations for processing high-dose U-233 in March. The company was forced to suspend its operational readiness review of the Initial Processing Campaign at Oak Ridge in January due to issues related to COVID-19, as well as difficulties operating in colder temperatures.

As part of a nonproliferation agreement, Canada and the U.S. undertook a multi-year campaign to ship liquid high-enriched uranium material from Chalk River to Savannah River.

State troopers and first responders at a TRM roadshow stop in Virginia. The display LWT cask can be seen at the far right in its shipping container. (Photos courtesy of DOE/NNSA)

In March 2012, during the Nuclear Security Summit in Seoul, South Korea, the governments of Canada and the United States committed to work cooperatively to repatriate approximately 6,000 gallons of high-enriched uranyl nitrate liquid (HEUNL) target residue material (TRM) stored at the Chalk River Laboratories in Ontario to the U.S. Department of Energy’s Savannah River Site in South Carolina. The announcement was part of a larger agreement between the two countries to reduce proliferation risks by consolidating high-enriched uranium at a smaller number of secure locations.

The IWTU liquid nitrogen storage system at the DOE’s Idaho National Laboratory Site. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) stated on February 22 that its Idaho National Laboratory Site contractor is operating the final test run of the Integrated Waste Treatment Unit (IWTU), running waste simulant through the facility to ensure the plant’s performance and personnel proficiency for upcoming radiological operations.

The NWMO said its Property Value Protection program satisfies one of the guiding principles set out to support local decision-making about Canada’s repository project. (Photo: NWMO)

Canada’s Nuclear Waste Management Organization (NWMO) said in a February news release that it has developed a program to protect the value of properties near the potential site in South Bruce, Ontario, for the country’s deep geological repository for used nuclear fuel. Along with Ignace in western Ontario, South Bruce is one of the two potential locations the NWMO has identified for hosting a deep geological repository.

According to the NWMO, the Property Value Protection program reflects a responsible commitment to the community and addresses questions the organization heard from residents about whether property values will be affected if South Bruce is selected for the repository. The program, which was developed in consultation with the community of South Bruce, will compensate residents if the sale of their properties is negatively affected by the project.

Holtec’s HI-STAR 190 spent nuclear fuel transport cask. India’s NPCIL ordered the company’s smaller HI-STAR 149 cask for use at its Kudankulam plant. (Photo: Holtec)

Holtec International announced yesterday that its India-based subsidiary, Holtec Asia, has received an order from Mumbai-based Nuclear Power Corporation of India Limited (NPCIL) for two HI-STAR 149 transport casks to serve the away-from-reactor storage facility for the Kudankulam nuclear power plant.

A rendering of Holtec International's interim spent fuel repository. (Image: Holtec International)

An article published on the Carlsbad Current-Argus news site on February 5 presents the wide gap between lawmakers in New Mexico on either side of the issue of temporary storage of spent nuclear fuel in the state.

The article noted that two identical bills—Senate Bill 54 and House Bill 127, which advanced in legislative committees last week—would block a spent fuel storage facility in New Mexico by prohibiting state agencies from issuing permits for such a facility.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

Rendering of the Forsmark geologic repository for spent nuclear fuel in Sweden. Below ground, the repository covers three to four square kilometers at a depth of 500 meters. (Image: SKB)

The government of Sweden announced on January 27 that it has issued a permit to the Swedish Nuclear Fuel and Waste Management Company (SKB) to build a deep geological repository for spent nuclear fuel at Forsmark in the municipality of Östhammar. The government also issued a permit to construct a spent fuel encapsulation plant in Oskarshamn, where the country’s inventory of spent fuel is currently being stored.

Workers recently installed manipulator equipment at a full-scale mock-up of areas of the Hanford Site’s Waste Encapsulation and Storage Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced this week that preparations are well underway for the transfer of nearly 2,000 highly radioactive cesium and strontium capsules from the Waste Encapsulation and Storage Facility (WESF) to interim dry storage at the Hanford Site near Richland, Wash.

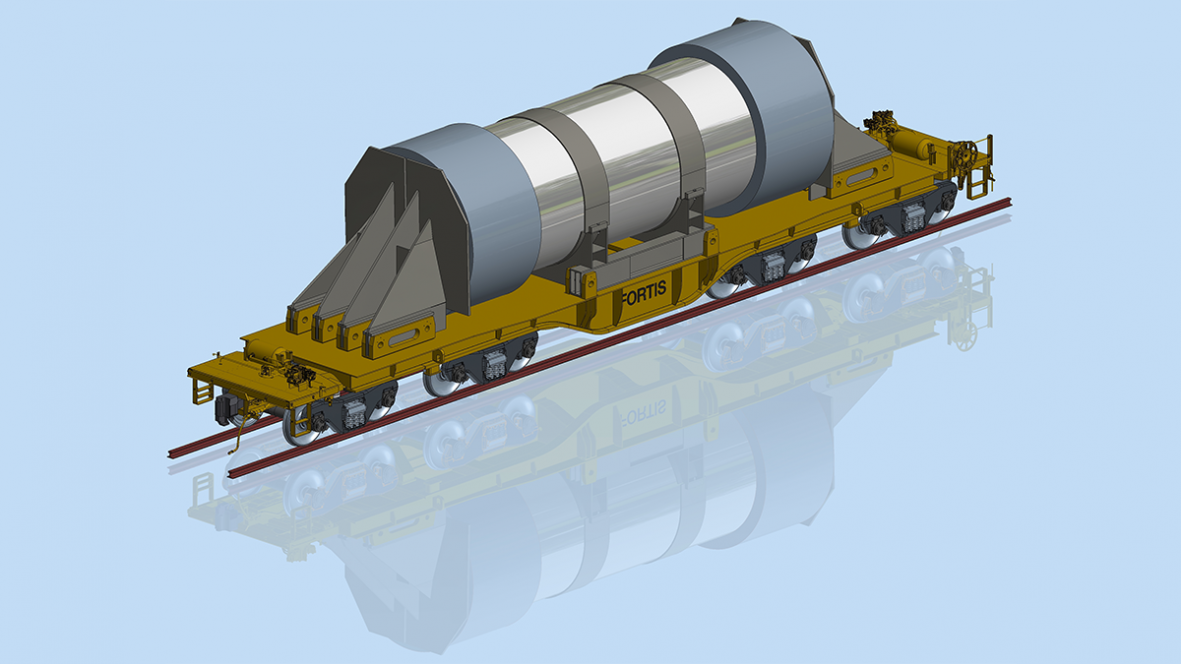

Graphical rendering of Fortis railcar design with spent nuclear fuel cask. (Image: DOE)

The Department of Energy has issued a request for proposals for the fabrication and testing of a prototype eight-axle railcar to carry the nation’s spent nuclear fuel and high-level radioactive waste. The heavy-duty, flat-deck railcar design known as “Fortis” received approval from the Association of American Railroads (AAR) in January 2021 to proceed to building and testing.

Employees wearing supplied-air equipment work through clues in an “escape room” during respiratory protection training at Hanford’s Volpentest HAMMER Federal Training Center. (Photo: DOE)

A new respiratory protection course at the Department of Energy’s Hanford Site near Richland, Wash., features an “escape room” in which employees wear supplied-air equipment while they answer questions, discover clues, and solve puzzles in a simulated work environment.