Workers recently installed manipulator equipment at a full-scale mock-up of areas of the Hanford Site’s Waste Encapsulation and Storage Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced this week that preparations are well underway for the transfer of nearly 2,000 highly radioactive cesium and strontium capsules from the Waste Encapsulation and Storage Facility (WESF) to interim dry storage at the Hanford Site near Richland, Wash.

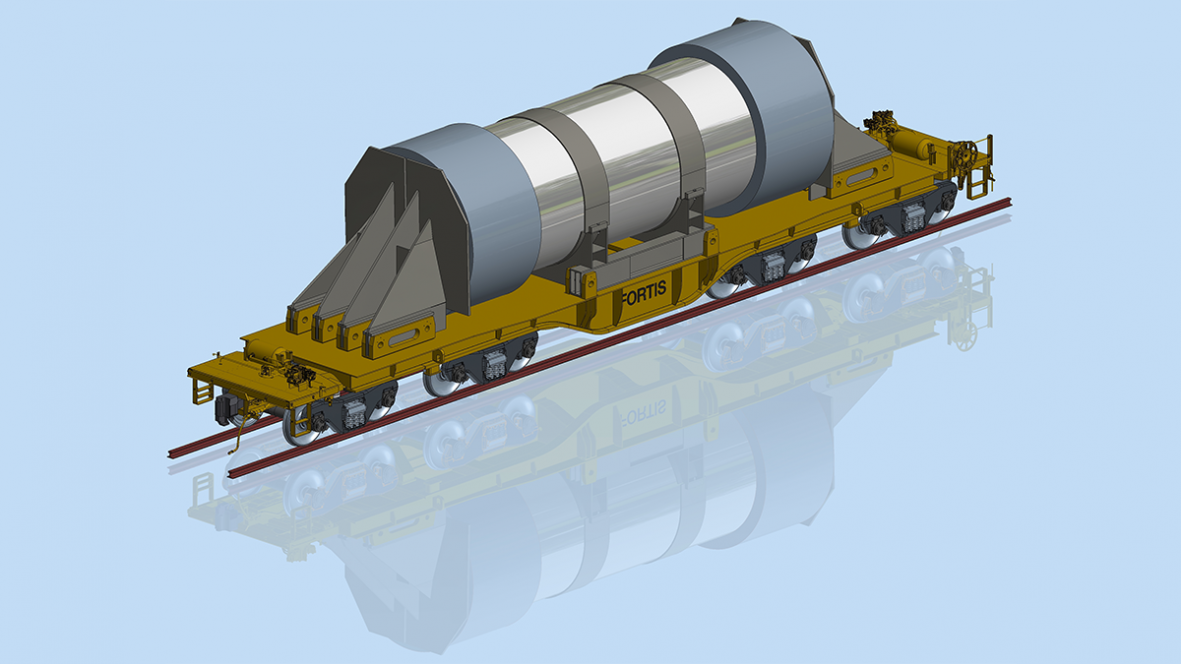

Graphical rendering of Fortis railcar design with spent nuclear fuel cask. (Image: DOE)

The Department of Energy has issued a request for proposals for the fabrication and testing of a prototype eight-axle railcar to carry the nation’s spent nuclear fuel and high-level radioactive waste. The heavy-duty, flat-deck railcar design known as “Fortis” received approval from the Association of American Railroads (AAR) in January 2021 to proceed to building and testing.

Employees wearing supplied-air equipment work through clues in an “escape room” during respiratory protection training at Hanford’s Volpentest HAMMER Federal Training Center. (Photo: DOE)

A new respiratory protection course at the Department of Energy’s Hanford Site near Richland, Wash., features an “escape room” in which employees wear supplied-air equipment while they answer questions, discover clues, and solve puzzles in a simulated work environment.

Click to see full image. (Photo: DOE)

Department of Energy contractor Central Plateau Cleanup Company recently completed final demolition activities at the Hanford Site’s former Plutonium Finishing Plant, which was once one of the most hazardous facilities in the DOE’s Office of Environmental Management (EM) cleanup complex.

Check out this time-lapse video of the plant’s demolition from October 2016 through November 2021.

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.

Nicholas Callihan, left, and Julissa Quinonez Chavez, front, complete training to become qualified as control room supervisor and utilities operator for the Waste Treatment and Immobilization Plant. (Photo: DOE)

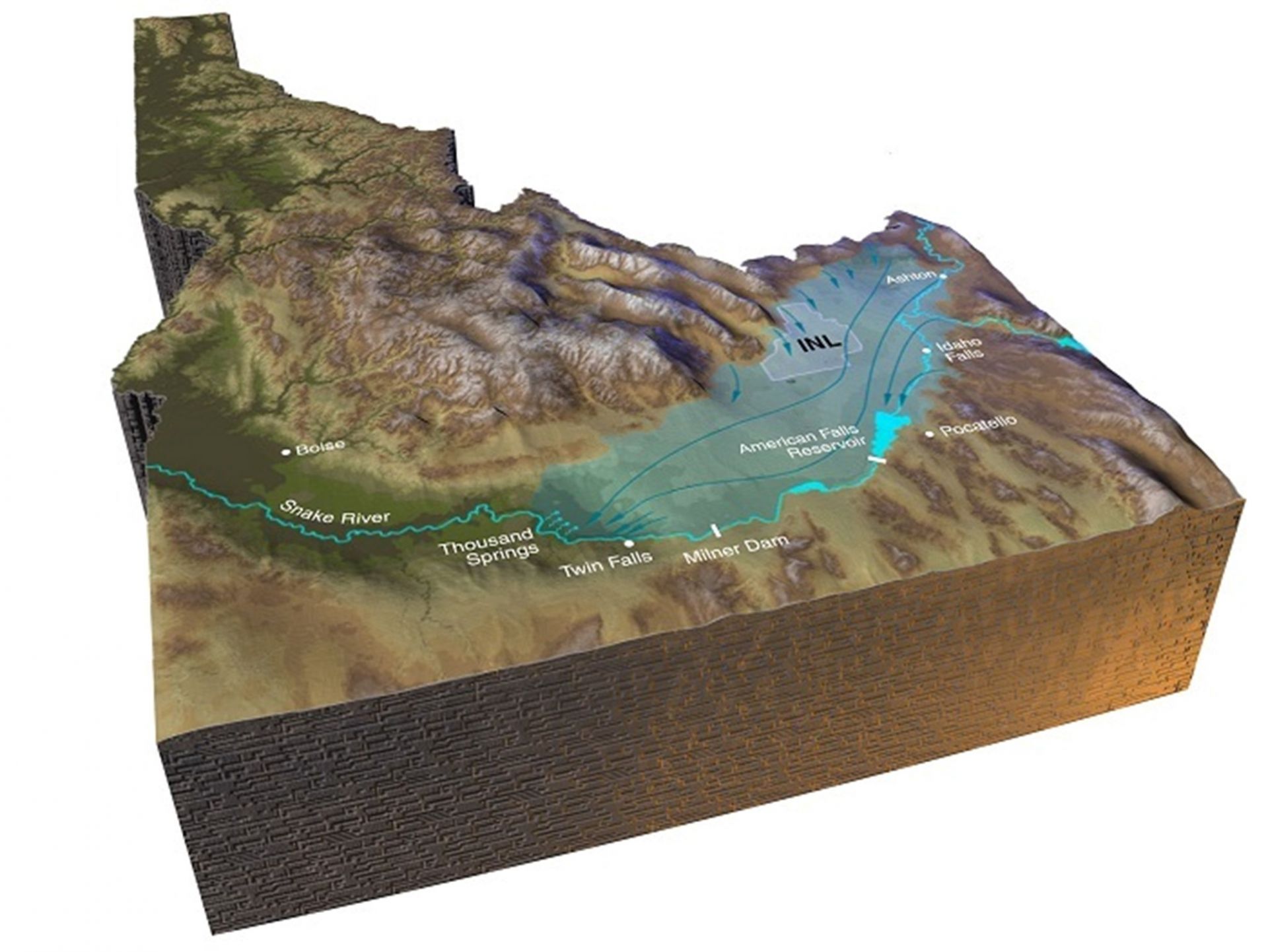

The underlying Snake River Plain Aquifer is considerably safer today following three decades of cleanup activities at the DOE’s Idaho National Laboratory Site. (Graphic: DOE)

When the Department of Energy, the state of Idaho, and the Environmental Protection Agency signed a federal facility agreement and consent order in December 1991, the agencies outlined a plan to investigate and clean up, if necessary, more than 500 individual waste areas within the 890-square-mile Idaho National Laboratory (INL) Site, which was established in 1949 to design, build, and test nuclear reactors.

Spent fuel in dry cask storage at the closed Kewaunee nuclear power plant. (Photo: NAC International)

The Department of Energy has restarted its consent-based siting process for identifying sites to store the nation’s spent nuclear fuel. Yesterday, the DOE issued a request for information that “will be used to further develop DOE’s consent-based siting process and overall waste management strategy in an equitable way.”

Electrician Ralph Bisla conducts tests of the finishing line inside Hanford’s WTP Low-Activity Waste Facility. (Photo: DOE)

Having completed all startup testing of components and systems, the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site near Richland, Wash., has moved to the commissioning phase, the Department of Energy’s Office of Environmental Management (EM) announced last week. During the commissioning phase, the final steps will be taken to prepare for the vitrification of radioactive and chemical waste as part of Hanford’s Direct-Feed Low-Activity Waste (DFLAW) program.

Crews pump waste from Hanford’s single-shell tanks to more stable double-shell tanks. (Photo: DOE)

The Department of Energy is considering solidifying 2,000 gallons of Hanford’s tank waste and disposing of it as low-level radioactive waste at an off-site facility. A virtual public meeting on the proposed disposal plan is scheduled for November 18.

DOE liquid waste contractor Savannah River Remediation is moving forward with Saltstone Disposal Unit projects to support the Salt Waste Processing Facility at the Savannah River Site.

The Department of Energy’s Office of Environmental Management (EM) has authorized the use of a second mega-volume saltstone disposal unit (SDU) at the Savannah River Site in South Carolina. Savannah River Remediation (SRR), EM’s liquid waste contractor at SRS, received Critical Decision-4 for Saltstone Disposal Unit 7, marking the final step in the approval process before beginning operations.

A truck loaded with waste crosses the scale at the East Tennessee Technology Park at Oak Ridge. Each truck used by Oak Ridge contractor UCOR is equipped with a unique radio frequency identification card that logs its movements and weight and registers the data in a database.

UCOR, the primary contractor for the Department of Energy’s Oak Ridge Office of Environmental Management (OEM), recently transitioned to a new waste tracking system that improves how shipments are tracked from work sites to disposal locations.

The new system includes upgraded radio frequency identification (RFID) tracking for trucks, as well as new hardware and software, allowing for an automated tracking operation that delivers up-to-the-minute waste disposal data.