The primary system of THETA at Argonne’s Mechanisms Engineering Test Loop Facility, where Oklo is conducting sodium thermal-hydraulic testing with support from a GAIN award announced in 2021. (Image: Argonne National Laboratory)

The Department of Energy and the Gateway for Accelerated Innovation in Nuclear (GAIN) on March 19 announced the second round of fiscal year 2024 voucher awards to three companies: Element Factory, Kanata America, and Oklo.

The Penn State RSEC recently received a SANS device. (Photo: Poornima Tomy/Penn State)

Staff and researchers at Penn State’s Radiation Science and Engineering Center (RSEC) will work this year to install a small angle neutron scattering (SANS) device and become the first and only U.S. university research reactor to host SANS capability. The $9.8 million device, donated by Helmholtz Zentrum Berlin (HZB) in Germany, will help researchers determine the structure of organic materials such as polymers, complex fluids, and biomolecules.

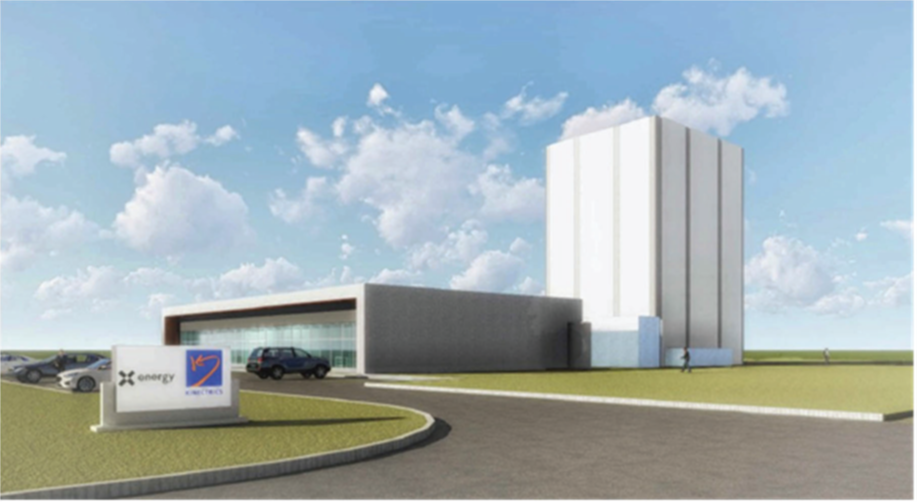

Concept art of the planned X-energy helium test facility. (Image: DOE OCED)

The Department of Energy’s Office of Clean Energy Demonstrations issued a final environmental assessment (EA) and finding of no significant impact in February for a cost-shared X-energy project to construct and operate a helium test facility (HTF) in Oak Ridge, Tenn. According to the EA, construction would begin in early 2024 and take X-energy and its contracted partner, Kinectrics, about one year to complete. the facility would then operate for six years, with the possibility of extensions for up to an additional 20 years, to test equipment for a demonstration of X-energy’s high-temperature, gas-cooled reactor technology and also to “serve the reactor community at large as the technology continues to develop and is adopted around the world.”

The Princeton Plasma Physics Laboratory. (Photo: PPPL)

A team of engineers, physicists, and data scientists from Princeton University and the Princeton Plasma Physics Laboratory (PPPL) have used artificial intelligence (AI) to predict—and then avoid—the formation of a specific type of plasma instability in magnetic confinement fusion tokamaks. The researchers built and trained a model using past experimental data from operations at the DIII-D National Fusion Facility in San Diego, Calif., before proving through real-time experiments that their model could forecast so-called tearing mode instabilities up to 300 milliseconds in advance—enough time for an AI controller to adjust operating parameters and avoid a tear in the plasma that could potentially end the fusion reaction.

An olive harvest. Europe produces 60 percent of the world's olive oil. (Photo: FAO)

The International Atomic Energy Agency is developing multiple methods to rapidly screen and authenticate the origin of foods like extra virgin olive oil. With recent heat waves and droughts affecting olive oil yields in Europe—which produces 60 percent of all olive oils—the European Commission has a problem: a growing black market in fake virgin and extra virgin olive oils. According to a 2022 EC report, olive oil is one of the most mislabeled food products in Europe.

TVA's Bull Run fossil plant. (Photo: TVA)

Type One Energy Group announced plans on February 21 to relocate its headquarters from Madison, Wis., to the Tennessee Valley Authority’s (TVA) Bull Run fossil plant in Clinton, Tenn., where it will build a stellarator fusion prototype machine. According to the company, the construction of the stellarator—called Infinity One—could begin in 2025, if necessary environmental reviews, partnership agreements, permits, and operating licenses are all in hand.

The Nine Mile Point nuclear power plant in Oswego, N.Y., site of a DOE hydrogen demonstration project. (Photo: DOE)

As hydrogen production increases worldwide, some see clean hydrogen as a game-changer when it comes to decarbonizing the steel industry.

Steel production is one of the “hard-to-abate” sectors of industry, which are responsible for about 30 percent of global carbon emissions. These industries are tough to decarbonize because the technologies either do not yet exist or are considered uneconomical.

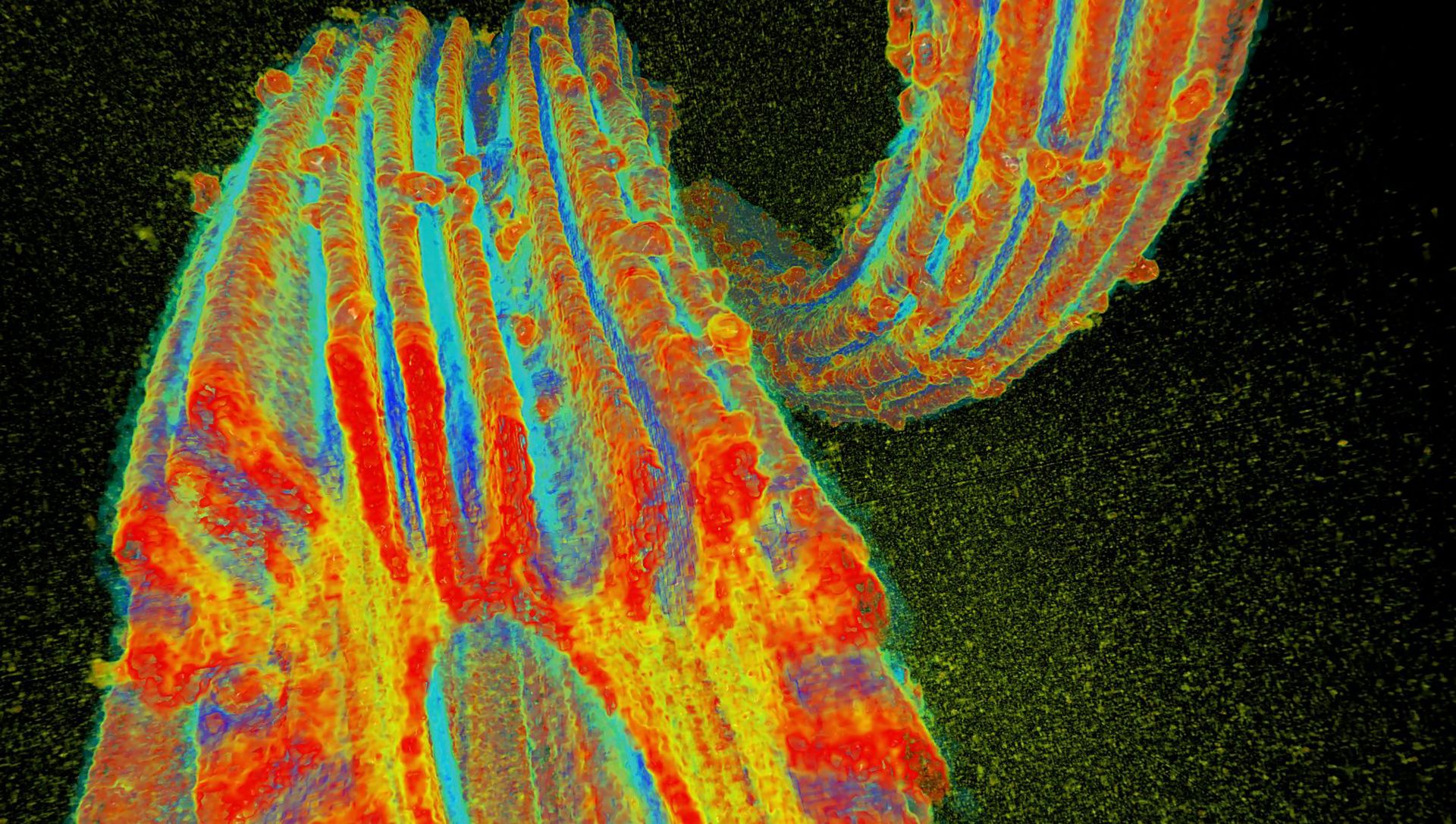

Researchers have been working frantically to develop an array of materials and fibers to economically extract uranium from seawater—and they have succeeded. PNNL scientists exposed this special uranium-sorbing fiber developed at ORNL to Pseudomonas fluorescens and used the Advanced Photon Source at Argonne National Laboratory to create a 3-D X-ray microtomograph to determine microstructure and the effects of interactions with organisms and seawater. (Image: PNNL)

America, Japan, and China are racing to be the first nation to make nuclear energy completely renewable. The hurdle is making it economical to extract uranium from seawater, because the amount of uranium in seawater is truly inexhaustible.

While America had been in the lead with technological breakthroughs from the Department of Energy’s Pacific Northwest and Oak Ridge National Laboratories, researchers at Northeast Normal University in China have sprung ahead. But these breakthroughs from both countries have brought the removal of uranium from seawater within economic reach. The only question is when will the source of uranium for our nuclear power plants change from mined ore to seawater extraction?

Radioisotopes target cancer, improve imaging, and have myriad other medical uses

ORNL radioisotope manufacturing coordinator Jillene Sennon-Greene places a shipment vial of actinium-225 inside the dose calibrator to confirm its activity is within customer specifications. (Photo: Carlos Jones/ORNL, DOE)

On August 2, 1946, 1 millicurie of the isotope carbon-14 left Oak Ridge National Laboratory, bound for the Barnard Free Skin and Cancer Hospital in St. Louis, Mo.

That tiny amount of the radioisotope was purchased by the hospital for use in cancer studies. And it heralded a new peacetime mission for ORNL, built just a few years earlier for the production of plutonium from uranium for the Manhattan Project.

Concept art of the MARVEL microreactor (Image: INL)

The Department of Energy announced February 7 that fuel for the MARVEL microreactor, which Idaho National Laboratory plans to host inside the Transient Reactor Test (TREAT) facility, is now being fabricated by TRIGA International, with the first fuel delivery expected in spring 2025. MARVEL operation was expected “by the end of 2024” as recently as May 2023, but that timeline had shifted by October, when the DOE said MARVEL “is expected to be completed in early 2025.” Now, according to the DOE’s latest announcement, “Fuel loading for MARVEL is anticipated to occur in 2026, with the microreactor expected to be on line by 2027.”

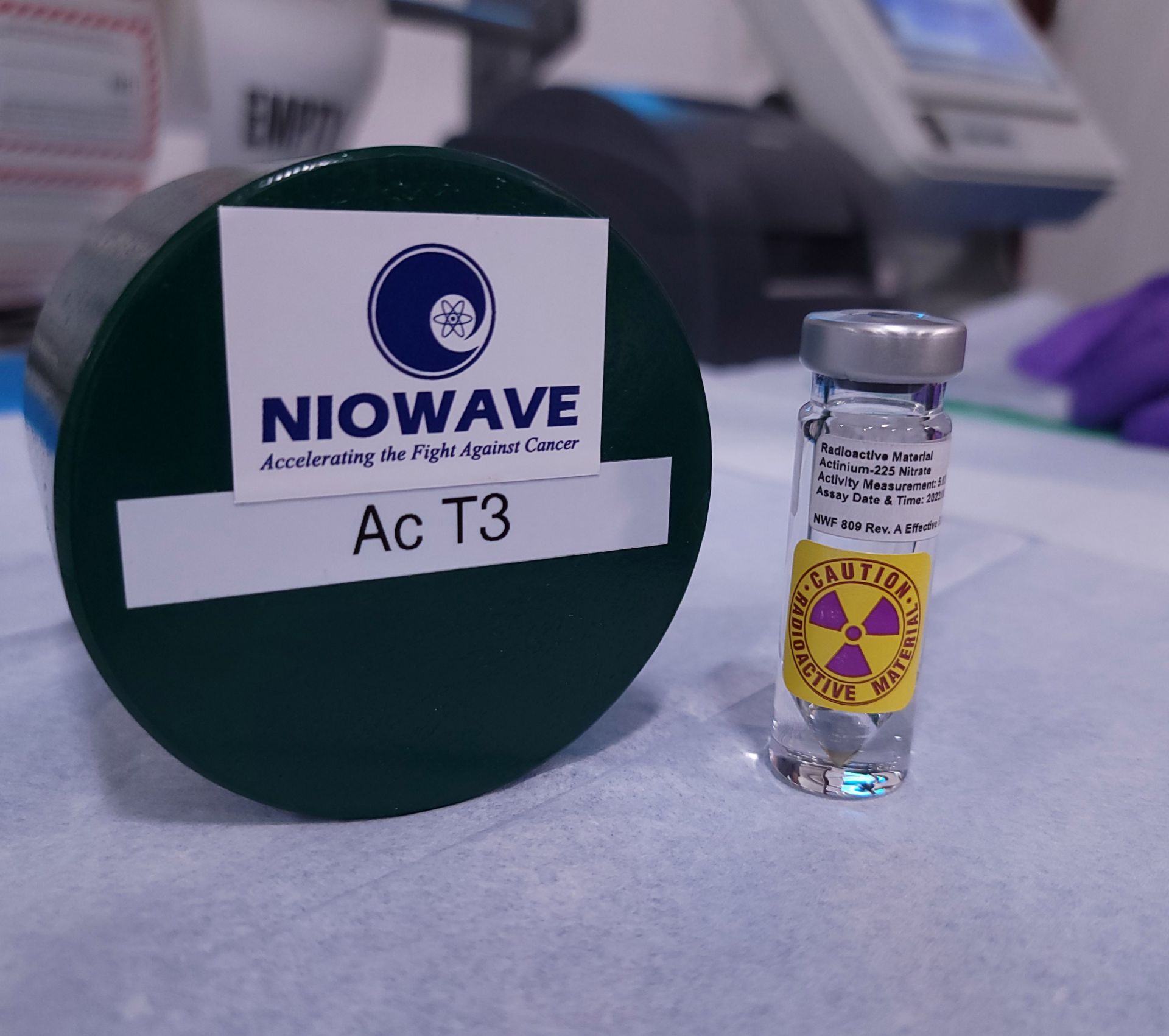

A vial of Ac-225 produced by Niowave stands next to its lead shipping pig. (Photo: Niowave)

According to the Council on Radionuclides and Radiopharmaceuticals, more than 82,000 nuclear imaging procedures using nuclear medicine are performed throughout the world every day. To administer these vital medical procedures, radiopharmaceutical companies and hospitals rely on a handful of producers of medical radioisotopes.

[Click image for full view.] More than 20 African countries have no radiotherapy treatment facilities. Darker blue areas indicate regions of greater population density, while radiotherapy centers are marked with red dots. (Image: IAEA)

More people in low- and middle-income countries who have head and neck cancer may be able to access lifesaving radiotherapy after research supported by the International Atomic Energy Agency has shown that fewer—but higher—doses of radiation treatment resulted in clinical outcomes similar to standard radiotherapy treatments. Reducing overall treatment times for this type of cancer through a treatment regimen called hypofractionation could help countries navigate resource constraints and shorten waitlists, enabling more patients to receive treatment while also reducing the cost and duration of care. The IAEA announced the findings in a news article published January 22.

-3 2x1.jpg)