Panelists for the session, from left, panel moderator Catherine Prat, Westinghouse Electric Company; Riaz Bandali, president of Nordion; Ben Goodrich, a director at TerraPower Isotopes; Ross Radel, chief technology officer at SHINE Technologies; Harsh Desai, chief commercialization officer at Zeno Power; and Alyse Huffman, a professional staff member for the Senate Committee on Energy and Natural Resources. (Photo: ANS)

“What can the atom do for you, other than produce electricity from nuclear reactors?” That was the question asked and answered during an ANS Annual Conference special plenary session on June 18, introduced by ANS President Ken Petersen and organized by the ANS Young Members Group. An expert panel discussed radioisotopes and their supply chains in the context of cancer treatment, product sterilization, power for remote applications, and used nuclear fuel recycling.

Orano CEO Nicolas Maes (left) and SHINE Technologies founder and CEO Greg Piefer shake hands after agreeing to cooperate on a pilot used fuel recycling facility. (Photo: Orano)

Orano and SHINE Technologies have agreed to cooperate in the development of a pilot plant capable of recycling used nuclear fuel from light water reactors on a commercial scale. In announcing the signing of a memorandum of understanding on Thursday, the companies said the selection of a site for the pilot U.S. facility is expected by the end of this year.

Schematic of a deep horizontal borehole repository for nuclear waste. (Image: Deep Isolation)

Waste disposal start-up Deep Isolation and fusion tech company SHINE Technologies have announced the completion of a collaborative study assessing the costs of disposing of radioactive byproducts from a pilot spent nuclear fuel recycling facility.

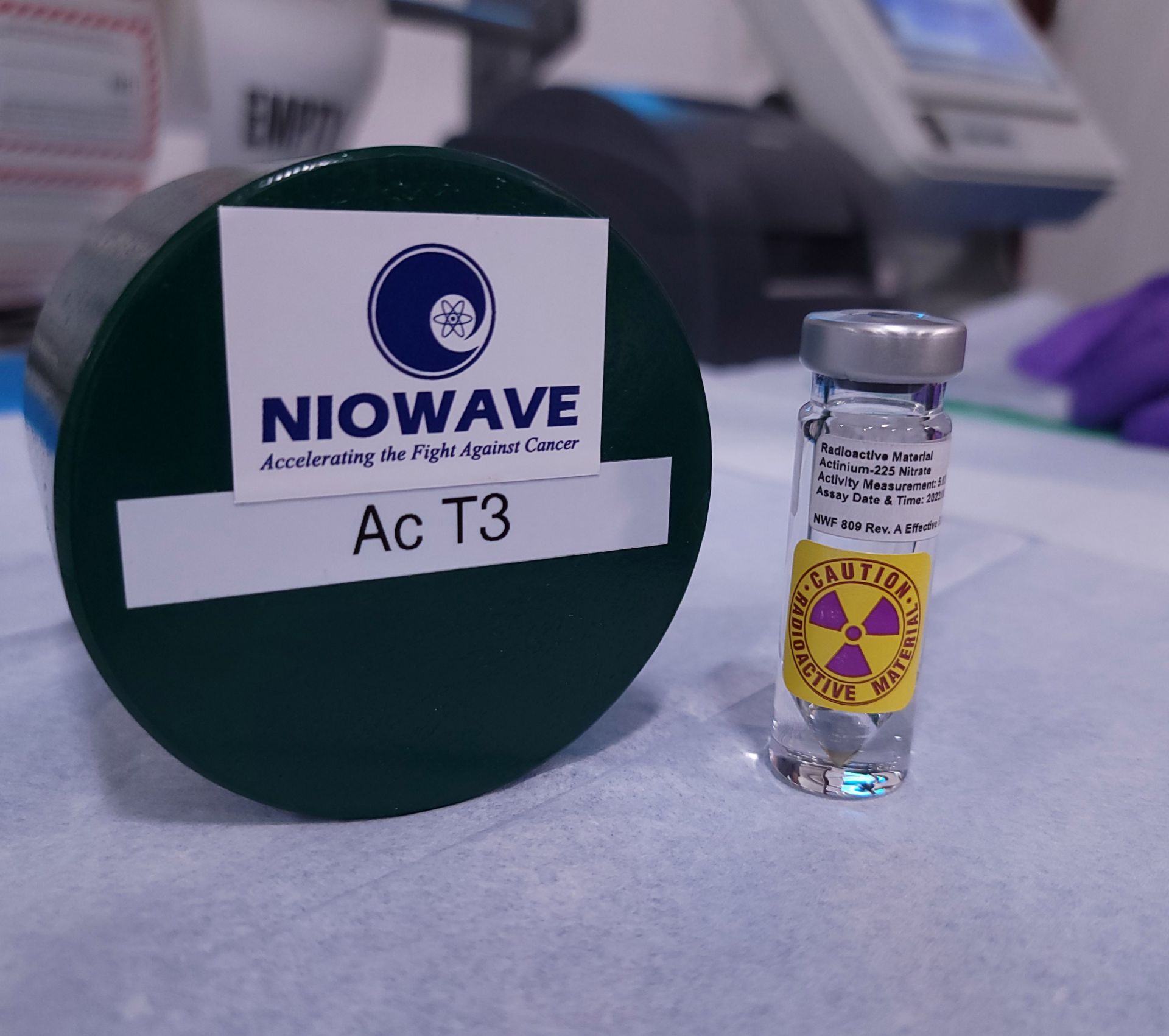

A vial of Ac-225 produced by Niowave stands next to its lead shipping pig. (Photo: Niowave)

According to the Council on Radionuclides and Radiopharmaceuticals, more than 82,000 nuclear imaging procedures using nuclear medicine are performed throughout the world every day. To administer these vital medical procedures, radiopharmaceutical companies and hospitals rely on a handful of producers of medical radioisotopes.

A still from a video on Westinghouse Electric Company’s eVinci microreactor, one of seven advanced reactor technologies that received support in GAIN’s latest round of nuclear energy vouchers. (Image: Westinghouse)

The Gateway for Accelerated Innovation in Nuclear (GAIN) announced December 19 that seven firms will get vouchers to access the nuclear research facilities and expertise of the national laboratory complex in the first round of fiscal year awards. Each company is paired with one or more national laboratories to work on concepts from advanced reactor fueling to fuel recycling to climate forecasting.

A spent nuclear fuel transportation container. (Photo: DOE)

Fusion systems company SHINE Technologies has notified the Nuclear Regulatory Commission that it intends to submit a license application to build and operate a pilot used nuclear fuel recycling facility.

SHINE Technologies founder and CEO Greg Piefer shows the hot cell banks that will be used to produce Lu-177. (Image: SHINE)

Fusion tech company SHINE Technologies announced that it is opening the largest facility in North America dedicated to the production of non-carrier-added lutetium-177, a medical isotope used in targeted cancer therapies.

SHINE’s Mo-99 production building under construction in October 2022. (Photo: SHINE)

Fusion development company SHINE Technologies announced that it will begin offering radiation effects testing in a dedicated facility on the company’s Janesville, Wis., campus later this year. SHINE will use high-energy fusion neutrons to test mission-critical components that are susceptible to radiation-harsh environments on behalf of its aerospace and defense customers.

The electron accelerator that will be used for Mo-99 production at NorthStar’s newly completed facility in Wisconsin. (Photo: NNSA)

NorthStar Medical Radioisotopes has completed construction and all equipment installation at its new facility in Beloit, Wis., to produce the medical radioisotope molybdenum-99 without the use of high-enriched uranium, the Department of Energy’s National Nuclear Security Administration announced last week.

A rendering of the SHINE medical isotope production facility planned for construction in Veendam, the Netherlands. (Image: SHINE)

SHINE Europe, a subsidiary of Wisconsin-based SHINE Technologies, will work with the Netherlands’ University Medical Center Groningen (UMCG) and Delft University of Technology (TU Delft) to produce a variety of terbium isotopes for use in nuclear medicine under a grant proposal approved by the Dutch government on October 17.

SHINE’s Mo-99 production facility under construction in Janesville, Wis. (Photo: SHINE)

SHINE Europe, a nascent subsidiary of Wisconsin-based SHINE Technologies, announced Wednesday that it has secured funding to begin designing an advanced medical isotopes facility in Veendam, the Netherlands. The new facility will use the same fusion-based neutron generator system SHINE is employing at its Janesville, Wis., facility to produce medical isotopes, including molybdenum-99, which is used in diagnostic imaging.

SHINE Technologies’ headquarters building in Janesville, Wis. (Photo: SHINE)

The Department of Energy’s National Nuclear Security Administration has issued a cooperative agreement worth $35 million to SHINE Technologies, based in Janesville, Wis., to support the commercial production of molybdenum-99, a critical isotope used in more than 40,000 medical procedures in the United States each day, including the diagnosis of heart disease and cancer.

A rendering of the SHINE medical isotope production facility planned for construction in Veendam, the Netherlands. (Image: Shine)

SHINE Medical Technologies plans to locate its European medical isotope production facility in the Netherlands after a yearlong search and a review of more than 50 proposals from sites across Europe. The company announced on May 20 that construction at the site should begin in 2023 with commercial production starting in late 2025.

.png)