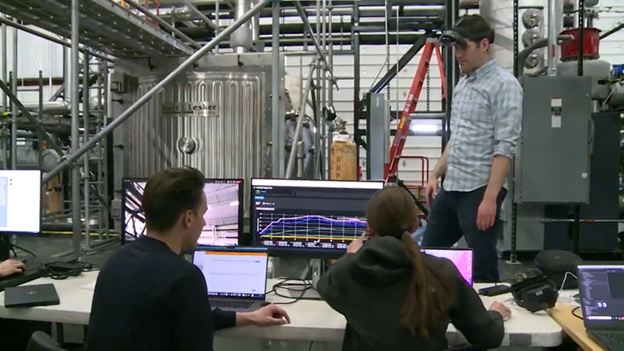

A screenshot taken from a INL video demonstrating MAGNET and its digital twin. (Source: INL)

Researchers at Idaho National Laboratory (INL) recently performed their first digital twin test of the Microreactor Agile Non-nuclear Experimental Testbed (MAGNET) and captured the demonstration in a video posted July 14. The digital twin—a virtual representation of a microreactor—was built using advancements in remote monitoring, autonomous control, and predictive capabilities that could help lower operating costs of microreactor technologies and enhance their safety.

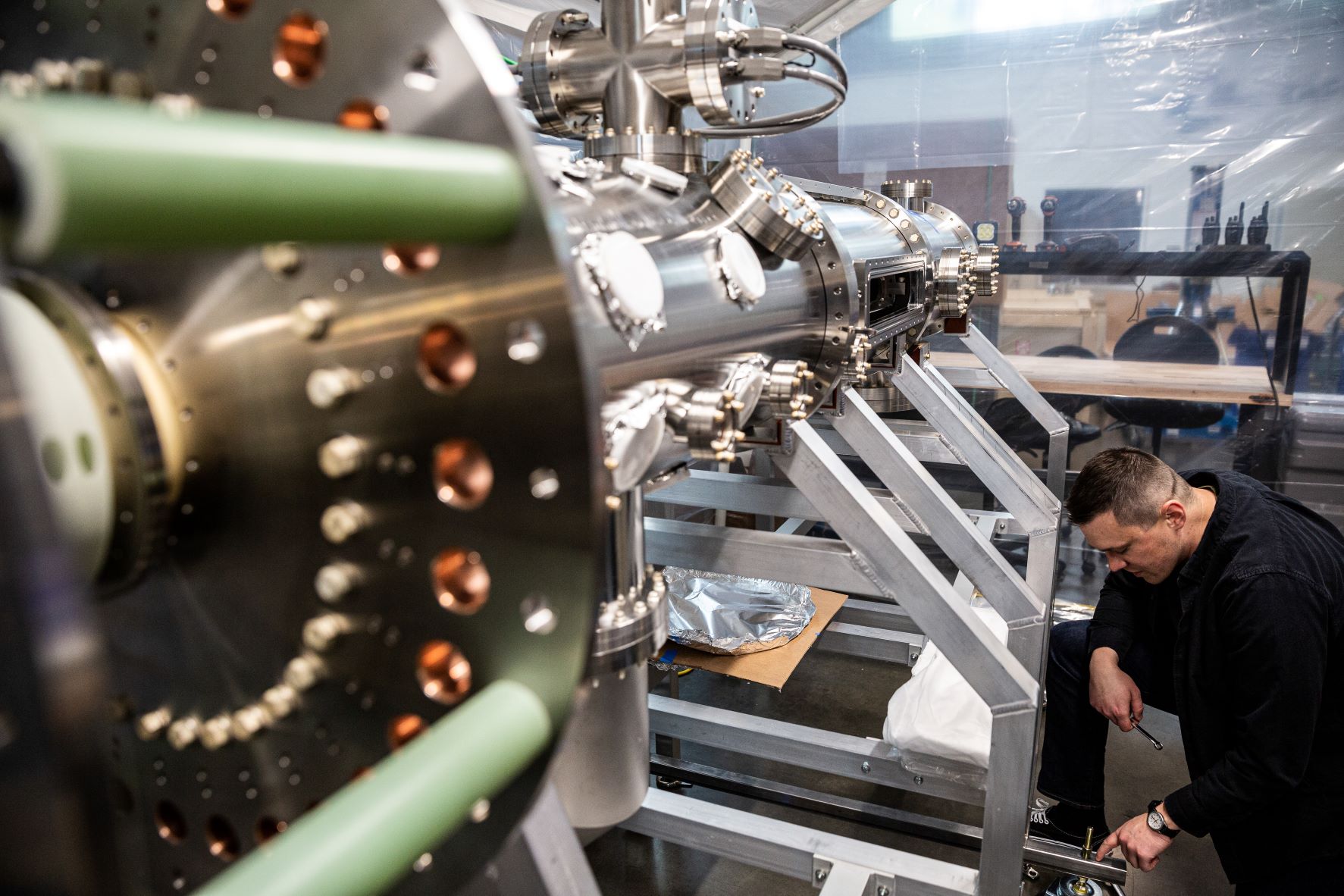

The first plasmas created in FuZE-Q, shown here during assembly, represent a key step towards fusion experiments with net energy output. (Photo: Zap Energy)

Zap Energy has created the first plasmas in its FuZE-Q machine—the company’s fourth prototype machine and the one it hopes will demonstrate a net energy gain from a Z-pinch fusion plasma just one millimeter in diameter and half a meter long. Zap Energy announced that engineering achievement and the close of $160 million in Series C funding in late June.

A conceptual illustration of a fission surface power system. (Image: NASA)

Three teams have been picked to design a fission surface power system that NASA could deploy on the moon by the end of the decade, NASA and Idaho National Laboratory announced today. A fission surface power project sponsored by NASA in collaboration with the Department of Energy and INL is targeting the demonstration of a 40-kWe reactor built to operate for at least 10 years on the moon, enabling lunar exploration under NASA’s Artemis program. Twelve-month contracts valued at $5 million each are going to Lockheed Martin (partnered with BWX Technologies and Creare), Westinghouse (partnered with Aerojet Rocketdyne), and IX (a joint venture of Intuitive Machines and X-energy, partnered with Maxar and Boeing).

(Photo: Clean Core Thorium Energy)

The Advanced Test Reactor (ATR) at Idaho National Laboratory will soon be irradiating fuel pellets containing thorium and high-assay low-enriched uranium (HALEU) developed by Clean Core Thorium Energy for use in pressurized heavy water reactors (PHWRs). Clean Core announced on June 14 that it will proceed with irradiation testing and qualification under an agreement with the Department of Energy; the plans have been in the works since at least 2020, when the DOE filed a National Environmental Policy Act (NEPA) disclosure for the work.

Session moderator Scott Hsu (left) led a discussion with (from left) Troy Carter, Kathy McCarthy, Artem Smirnov, Satoshi Konishi, and Jane Hotchkiss during an ANS Annual Meeting executive session on “The New Fusion Outlook.”

A “bold decadal plan” to accelerate fusion research, development, and demonstration in partnership with the private sector emerged from a March 2022 White House Fusion Summit and inspired the June 14 ANS Annual Meeting executive session titled “The New Fusion Outlook.” Moderator Scott Hsu, who is leaving a role as a program director for the Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) to become a senior adviser to the DOE’s undersecretary for science and innovation as well as lead fusion coordinator for the DOE, ably led a panel of fusion stakeholders representing universities, national laboratories, private fusion companies, and public policy and communication. The discussion intended to bring attendees with fission experience up to speed on the rapidly accelerating area of fusion energy and explore how the fusion energy community can work toward a unique path for fusion energy regulation and public engagement.

Artist’s rendering of BWXT’s Project Pele transportable reactor modules arriving for set up and operation. (Image: BWXT)

BWX Technologies, Inc., will deliver the first microreactor in the United States under a contract awarded by the U.S. Department of Defense Strategic Capabilities Office (SCO), the company announced today. BWXT will have two years to build a transportable microreactor prototype to the SCO’s Project Pele specifications and deliver it to Idaho National Laboratory for testing under a cost-type contract valued at about $300 million.

A depiction of an electrolyzer from Bloom Energy. (Photo: Bloom Energy)

Using nuclear power technology to produce clean hydrogen is getting a visibility boost as the Department of Energy hosts a virtual three-day (June 6–8) Annual Merit Review and Peer Evaluation Meeting on the agency’s efforts to accelerate clean hydrogen production. On June 6, the DOE announced a notice of intent (NOI) to fund the Bipartisan Infrastructure Law’s $8 billion program to develop regional clean hydrogen hubs (H2Hubs) and the launch of a new Hydrogen Shot Incubator Prize that seeks “disruptive technologies” to reduce the cost of clean hydrogen production. That same day, Westinghouse Electric Company and Bloom Energy Corp. (a maker of solid oxide electrolyzer technology) announced a letter of intent to develop electrolyzers for use in the commercial nuclear power market and said they are “well positioned to support the U.S. Department of Energy’s developing hydrogen hubs.”

The Panther T16 sprays fixative with a high-pressure water cannon onto X-326 building debris at the Portsmouth Site. (Photo: DOE)

Workers at the Department of Energy’s Portsmouth Site in Ohio have been using a new tool as part of the dust-suppression systems for the X-326 process building demolition project. The X-326 was one of three massive process buildings originally built to enrich uranium at the site, which was in operation starting in the 1950s. Environmental remediation of the site began in 1989, and deactivation and decommissioning activities began in 2011. Demolition of the facility has led to a dusty work environment.

During the Hanford Site's Direct-Feed Low-Activity Waste Program treatment operations, the Waste Treatment and Immobilization Plant, background, will feed liquid waste to the Liquid Effluent Retention Facility, foreground, through a primary transfer line pictured here. (Photo: DOE)

Work crews at the Department of Energy's Hanford Site recently completed the first transfer of test water from the Waste Treatment and Immobilization Plant's Effluent Management Facility to the nearby Liquid Effluent Retention Facility (LERF). The transfer of 6,000 gallons was the first simulation of the process that will be used to treat secondary liquid waste from the plant’s Low-Activity Waste Facility during operations to treat tank waste.

“This is a tremendous accomplishment that culminates years of work by our team and alumni toward being ready for hot commissioning,” said Valerie McCain, project director and senior vice president for Bechtel National, Inc. “It’s an important step for the entire Hanford team and our collective mission of protecting the Columbia River and its shoreline communities.”

Bechtel National is a contractor of the DOE's Office of Environmental Management's Office of River Protection.

The final legacy TRU waste shipment from Savannah River Site departs the site in mid-April, on its way to WIPP in southeastern New Mexico for permanent disposal. (Photo: DOE)

The Department of Energy reported this month that the final container of legacy transuranic waste from the Savannah River Site arrived at the Waste Isolation Pilot Plant for permanent disposal on the afternoon of April 14. The shipment capped the end of a journey for 239 shipments that began in 2011.

In all, trucks that carried the shipments weighed a combined 11,402,000 pounds and travelled more than 347,000 miles to the WIPP site.

Representatives from Westinghouse and Penn State met at Westinghouse headquarters to sign a memorandum of understanding and enter a partnership focused on researching and developing microreactors. From left: Jason Beebe, director of the global transformation office at Westinghouse; Michael Valore, senior director of advance reactor commercialization, Westinghouse; Mike Shaqqo, senior vice president of advanced reactors, Westinghouse; Lora Weiss, senior vice president for research at Penn State; Jean Paul Allain, head of the Ken and Mary Alice Lindquist Department of Nuclear Engineering at Penn State; Geanie Umberger, associate vice president for research and director of industry research collaborations at Penn State; Saya Lee, assistant professor of nuclear engineering; Elia Merzari (back), associate professor of nuclear engineering; and Hilary Ruby, director of transformation for the Americas Operating Plant Services Business Unit at Westinghouse. (Photo: Westinghouse)

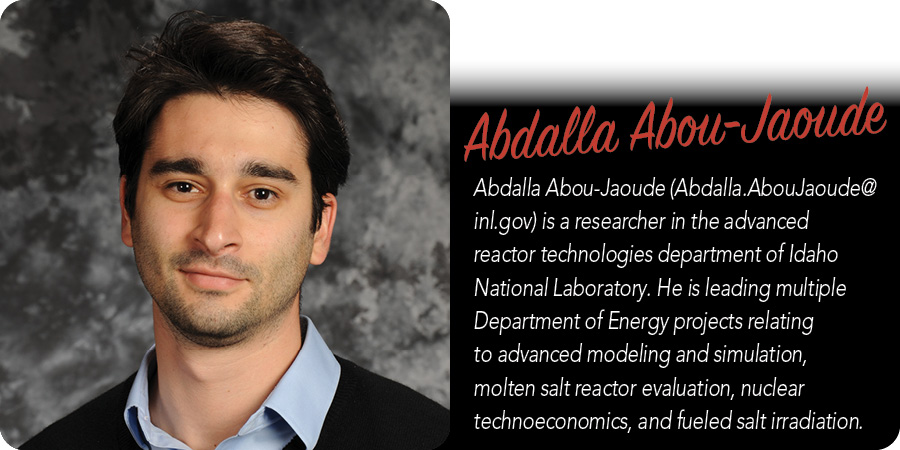

THETA pictured in Argonne National Laboratory’s METL lab. (Photo: ANL)

The Thermal Hydraulic Experimental Test Article (THETA) at Argonne National Laboratory is now operating and providing data that could support the licensing of liquid-metal fast reactor designs by validating thermal-hydraulic and safety analysis codes. The new equipment has been installed in Argonne’s Mechanisms Engineering Test Loop (METL), and its first experiments are supporting data validation needs of Oklo, Inc., by simulating normal operating conditions as well as protected and unprotected loss-of-flow accidents in a sodium-cooled fast reactor.

Alkali-silica reaction was confirmed at the Seabrook nuclear power plant in 2010. (Photo: NextEra Energy Resources)

Concrete structures built to last for decades, including reactor containment buildings and other nuclear power plant structures, are subject to the alkali-silica reaction (ASR), a reaction between alkali ions found in cement and silica, the two main components of concrete. The reaction forms a gel that absorbs water and expands over time, causing a buildup of pressure within the concrete that can eventually lead to cracking and deterioration.

Researchers at Argonne National Laboratory have successfully used electrochemical impedance spectroscopy (EIS) to detect ASR in the lab and believe it could be used for cost-effective, nondestructive testing at nuclear power plants.

An aerial view of the Facility for Rare Isotope Beams on the Michigan State University campus in East Lansing, Mich. (Photo: FRIB)

Michigan State University’s Facility for Rare Isotope Beams (FRIB) officially opened yesterday with a ribbon-cutting ceremony attended by Energy Secretary Jennifer Granholm, elected officials, and guests who had supported the project during its planning and construction, including ANS Executive Director/Chief Executive Officer Craig Piercy. They were there to celebrate the completion—on time and within budget—of the world’s most powerful heavy-ion accelerator and the first accelerator-based Department of Energy Office of Science user facility located on a university campus.