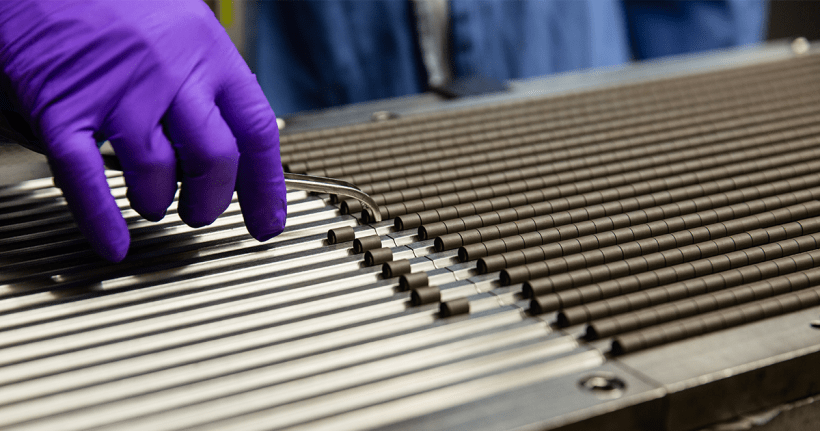

ADOPT fuel pellets developed by Westinghouse through the DOE's Accident Tolerant Fuel Program. (Photo: Westinghouse)

Westinghouse Electric Company and Southern Nuclear have agreed to a plan to install four Westinghouse lead test assemblies in Vogtle-2, a 1,169-MWe pressurized water reactor located in Waynesboro, Ga. Four lead test assemblies containing uranium enriched up to 6 percent U-235 will be loaded in Vogtle-2 in 2023, marking the first time that fuel rods with uranium enriched above 5 percent U-235 are put in use in a U.S. commercial power reactor.

A cask of HEU arrives at the H Canyon facility. (Photo: DOE)

The Department of Energy announced yesterday that Secretary of Energy Achievement Awards were presented to a team of Savannah River Site employees for the completion of the multiyear Target Residue Material (TRM) campaign to support global nuclear security goals.

SRS is a 310-square-mile site located in South Carolina. It encompasses parts of Aiken, Barnwell, and Allendale counties and is bordered on the west by the Savannah River and the state of Georgia.

An illustration of the two inertial confinement fusion designs reaching the burning plasma regime, as published in a recent article in Nature. (Image: LLNL)

One of the last remaining milestones in fusion research before attaining ignition and self-sustaining energy production is creating a burning plasma, where the fusion reactions themselves are the primary source of heating in the plasma. A paper published in the journal Nature on January 26 describes recent experiments at Lawrence Livermore National Laboratory’s National Ignition Facility (NIF) that have achieved a burning plasma state.

Oak Ridge before-and-after views: At left is the Oak Ridge Gaseous Diffusion Plant when it was closed in the late 1980s, and at right is a view of the site today, known as the East Tennessee Technology Park. (Photo: DOE)

Energy secretary Jennifer Granholm honored a Department of Energy Office of Environmental Management (EM) team from Oak Ridge with the Secretary of Energy’s Achievement Award during a virtual ceremony yesterday for successfully removing a former uranium enrichment complex. The project cleared 13 million square feet of deteriorated, contaminated structures from the site.

Click to see full image. (Photo: DOE)

Department of Energy contractor Central Plateau Cleanup Company recently completed final demolition activities at the Hanford Site’s former Plutonium Finishing Plant, which was once one of the most hazardous facilities in the DOE’s Office of Environmental Management (EM) cleanup complex.

Check out this time-lapse video of the plant’s demolition from October 2016 through November 2021.

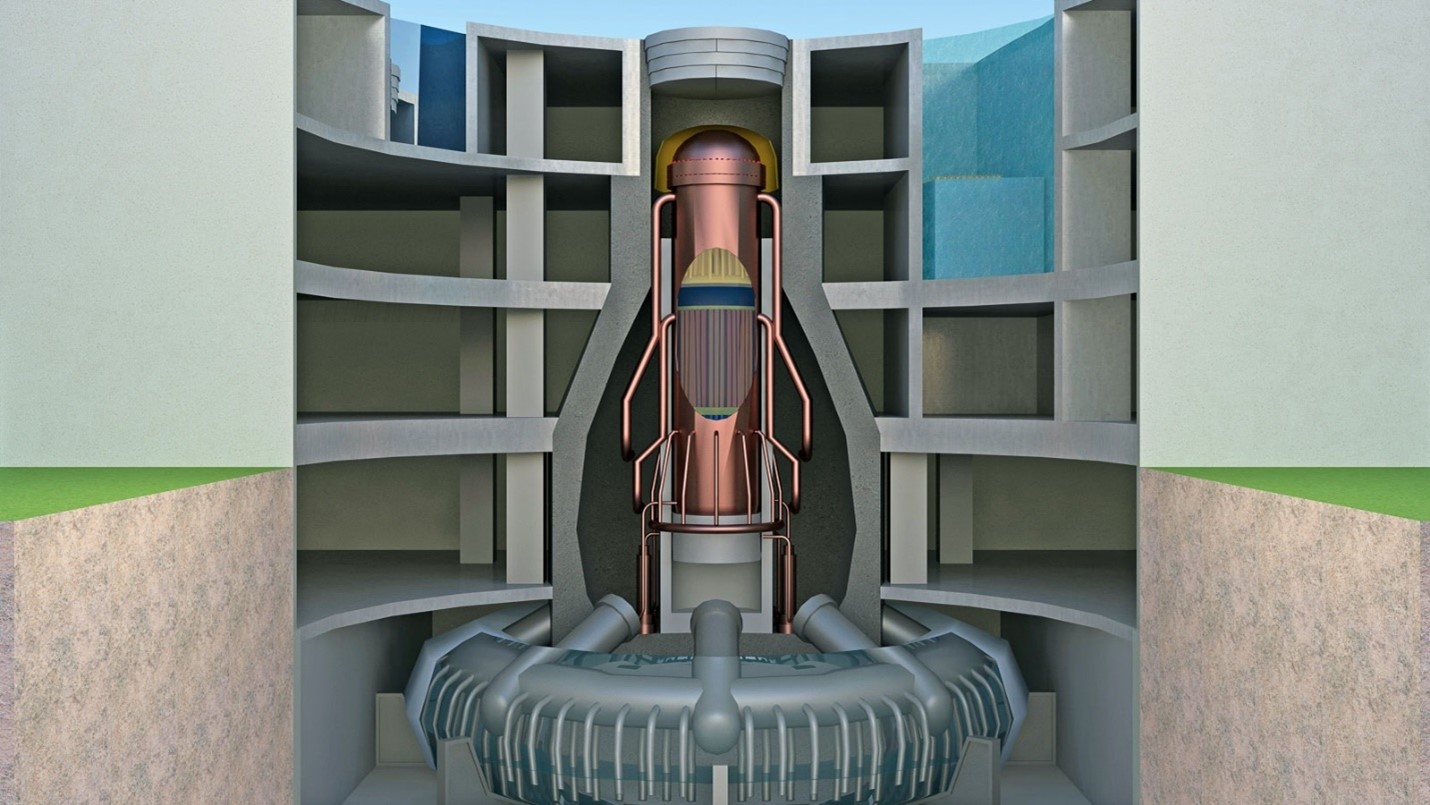

A cutaway view of a nuclear reactor. Its construction consists of two essential material types: fuel, which comprises the rods and cores that hold the fuel (center vertical bands); and structural, those parts of the reactor that house the fuel materials. (Graphic: Shutterstock/petrov-k)

Researchers from the Department of Energy’s Argonne National Laboratory are developing a “tool kit” based on artificial intelligence that will help better determine the properties of materials used in building a nuclear reactor.

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.

The Summit supercomputer at Oak Ridge National Laboratory began operations in 2018. (Photo: ORNL)

The Department of Energy has announced $9.25 million for research into the behavior and properties of structural materials under molten salt reactor conditions through collaborations using the DOE’s high-performance supercomputers.

The NuScale small modular reactor control room simulator will provide the authentic feel of being in the control room at a 12-unit SMR plant. (Photo: Rodolfo Vaghetto)

The Texas A&M Engineering Experiment Station (TEES) has installed the NuScale small modular reactor control room simulator at the Center for Advanced Small Modular and Micro Reactors (CASMR).

TEES performs collaborative research through universities, national laboratories, and state and federal agencies with the goal of finding solutions to global technical challenges.