Crews move equipment used to inspect drums holding diluted plutonium into a storage site in K Area at the Savannah River Site. Photo: DOE

Workers at the Department of Energy’s Savannah River Site in South Carolina recently finished transferring equipment to the site’s K Area in preparation of shipping downblended plutonium to the Waste Isolation Pilot Plant in New Mexico for disposal. The plutonium is part of the 34 metric tons of surplus plutonium the National Nuclear Security Administration plans to ship to WIPP under the “dilute and dispose” option the department adopted following the cancellation of the MOX Fuel Fabrication Facility project.

Workers remove asbestos siding panels from a Portsmouth Gaseous Diffusion Plant building. Photo: Business Wire

Fluor-BWXT Portsmouth, a joint venture of Fluor and BWX Technologies, along with engineering company Jacob, have received a contract extension valued at up to $690 million, including options, from the Department of Energy. The contract, announced April 6, is for environmental management work at the former Portsmouth Gaseous Diffusion Plant near Piketon, Ohio.

The outside of the DIII-D tokamak, where testing that supports the development of the Compact Advanced Tokamak has been performed. Photo: General Atomics

Scientists at the DIII-D National Fusion Facility have published research on a compact fusion reactor design they say could be used to develop a pilot-scale fusion power plant. According to General Atomics (GA), which operates DIII-D as a national user facility for the Department of Energy’s Office of Science, the Compact Advanced Tokamak (CAT) concept uses a self-sustaining configuration that can hold energy more efficiently than in typical pulsed configurations, allowing the plant to be built at a reduced scale and cost.

Photos of physicist Alessandro Bortolon and the element boron; graph and photo showing the interior of a tokamak. Credit: Alexander Nagy and Alessandro Bortolon/Collage courtesy of Elle Starkman, PPPL

Research led by scientists at the Department of Energy's Princeton Plasma Physics Laboratory (PPPL) provides new evidence that particles of boron, the main ingredient in Borax household cleaner, can coat internal components of doughnut-shaped plasma devices known as tokamaks and improve the efficiency of the fusion reactions, according to an article published on Phys.org on April 2.

ANS flooding and seismic consensus standards assist the NRC and DOE in buttressing nuclear facility safety policies

April 2, 2021, 2:47PMNuclear NewsLeah Parks, Carl Mazzola, Jim Xu, and Brent Gutierrez A map of Japan highlighting the Fukushima prefecture.

March 11 will mark the 10-year anniversary of the Fukushima Daiichi event, when a 45-foot tsunami, caused by the 9.0-magnitude Great Tohoku Earthquake, significantly damaged the reactors at Japan’s Fukushima Daiichi nuclear power plant. In response to this event, the U.S. Nuclear Regulatory Commission took actions to evaluate and mitigate beyond-design-basis events, including a new requirement for the staging of so-called Flex equipment, as well as changes to containment venting and improvements to emergency preparedness. The U.S. Department of Energy also addressed beyond-design-basis events in its documented safety analyses.

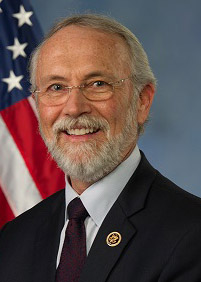

U.S. Rep. Dan Newhouse (R., Wash.) observes as (from left) Energy Northwest CEO Brad Sawatzke, X-energy CEO Clay Sell, and Grant PUD CEO Kevin Nordt sign the TRi Energy Partnership MOU on April 1 at the Port of Benton in Richland, Wash. Photo: Energy Northwest

Building the nation’s first advanced reactor is the goal of a partnership formed between X-energy, Energy Northwest, and the Grant County (Washington) Public Utility District (PUD).

The TRi Energy Partnership will support the development and demonstration of X-energy’s Xe-100 high-temperature gas reactor, which was selected by the Department of Energy for a cost-shared commercial demonstration by 2027 through the DOE’s Advanced Reactor Demonstration Program (ARDP). The new partnership was announced on April 1, when Clay Sell, X-energy’s chief executive officer; Brad Sawatzke, Energy Northwest’s CEO; and Kevin Nordt, the Grant County PUD’s CEO, met in Richland, Wash., to sign a memorandum of understanding.

Demolition begins on the six-story, 255,000-square-foot Building 9207, the final building in the former Biology Complex at Oak Ridge. Photo: DOE

Workers with the Department of Energy’s Office of Environmental Management (EM) recently began demolishing the last facility standing in the former Biology Complex at the Y-12 National Security Complex at the Oak Ridge Reservation in Tennessee.

As announced by EM on March 23, removal of the massive six-story, 255,000-square-foot Building 9207 creates a new chapter of transformation and modernization for Y-12. Completion of the Biology Complex demolition is one of EM’s 2021 priorities.

According to EM, the facilities in the Biology Complex presented significant structural risks due to their deterioration, and their condition landed them on DOE’s list of high-risk excess contaminated facilities.

Savannah River’s DWPF has been pouring high-level waste canisters for a quarter of a century. Photo: DOE

The month of March marked the 25th year of radiological operations for the Defense Waste Processing Facility (DWPF) at the Department of Energy’s Savannah River Site in South Carolina. Radiological operations at DWPF, which is used to treat Savannah River’s high-level radioactive tank waste, began on March 12, 1996, with the first canister of vitrified waste poured on April 29 that year.

To date, more than 4,200 stainless steel canisters of vitrified waste have been poured at DWPF, according to the DOE.

The only operating waste vitrification plant in the nation, DWPF is operated by Savannah River Remediation, the DOE’s liquid waste contractor at the site. According to the DOE, DWPF operations are expected to continue for approximately 15 more years, and about 4,000 more canisters are scheduled to be produced. The DOE expects to begin hot operations at a second waste vitrification plant later this year at its Idaho National Laboratory site.

The first wall section of Saltstone Disposal Unit 8 is being constructed at the Savannah River Site. Source: DOE

The first wall section of Saltstone Disposal Unit 8 (SDU 8) at the Department of Energy's Savannah River Site in South Carolina was installed earlier this month.

SDU 8 will stand 43 feet tall and 375 feet in diameter, and have a 33-million-gallon capacity, just like two SDUs built recently at the site. The 25 wall sections of SDU 8 are being constructed using high-strength, reinforced concrete and will be wrapped with seven layers of more than 300 miles of steel cable for added strength.

The flooring of SDU 8 is more than halfway complete. The concrete floor sits on top of a multilayer foundation: a geosynthetic clay liner and high-density plastic liner sandwiched between two concrete layers called “mud mats.” The floor is being completed in 14 sections.

The disposal units are built to safely and permanently contain decontaminated salt solution processed at Savannah River, the DOE reported on March 9.

Five former assistant secretaries of energy for the Office of Nuclear Energy—a position given the designation “NE-1”—gathered for a virtual panel discussion hosted by the American Nuclear Society on March 26. Rita Baranwal, John Kotek, Peter Lyons, William D. Magwood, and Warren “Pete” Miller each participated in the free event that was moderated by Benjamin Reinke, the former executive director in the secretary of energy’s Office of Strategic Planning and Policy.

Five former assistant secretaries of energy for the Office of Nuclear Energy—a position given the designation “NE-1”—gathered for a virtual panel discussion hosted by the American Nuclear Society on March 26. Rita Baranwal, John Kotek, Peter Lyons, William D. Magwood, and Warren “Pete” Miller each participated in the free event that was moderated by Benjamin Reinke, the former executive director in the secretary of energy’s Office of Strategic Planning and Policy. The Gateway for Accelerated Innovation in Nuclear (GAIN) announced that three nuclear technology companies—Radiant, Oklo, and Lightbridge—will receive GAIN nuclear energy vouchers to accelerate the innovation and application of advanced nuclear technologies.

The Gateway for Accelerated Innovation in Nuclear (GAIN) announced that three nuclear technology companies—Radiant, Oklo, and Lightbridge—will receive GAIN nuclear energy vouchers to accelerate the innovation and application of advanced nuclear technologies.