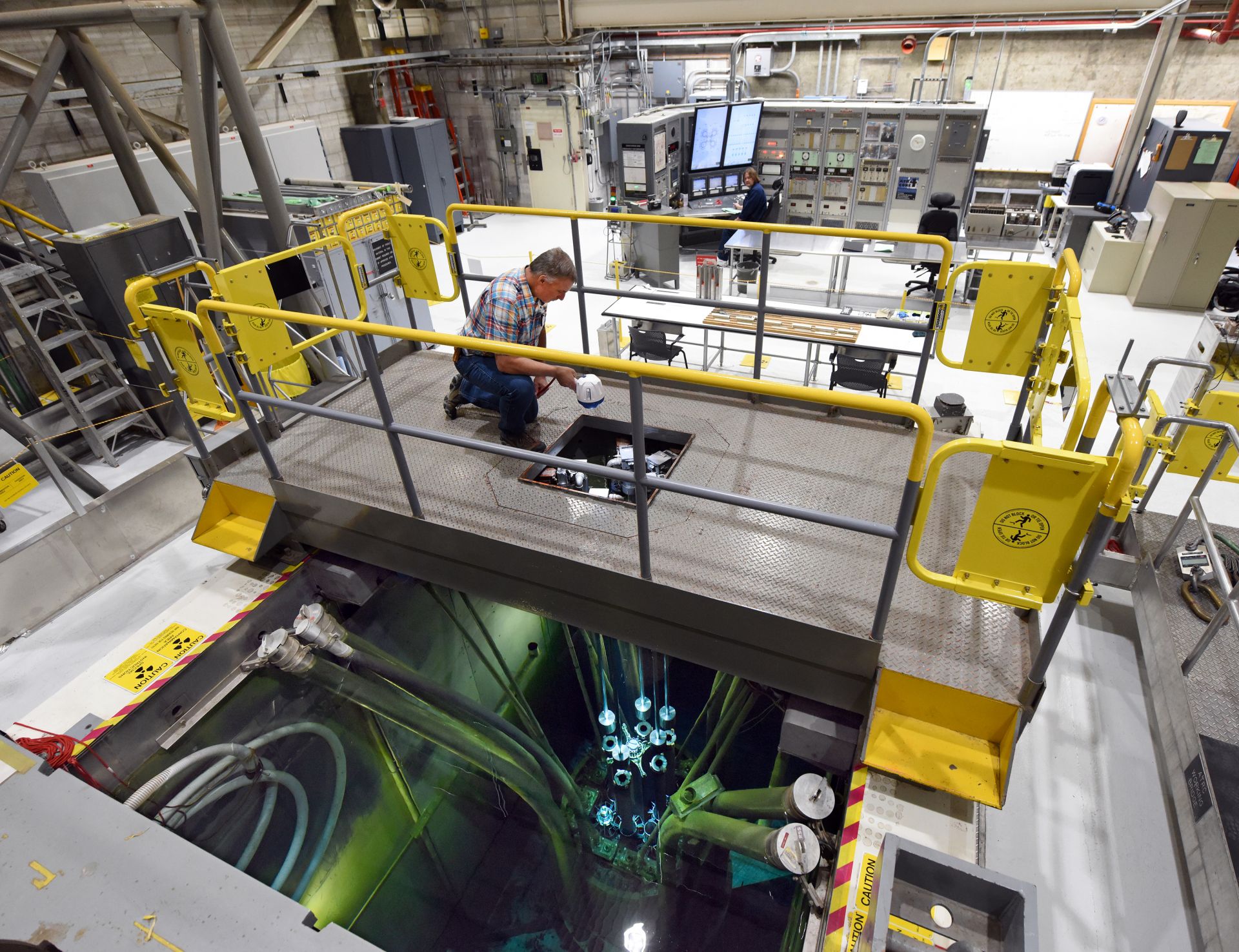

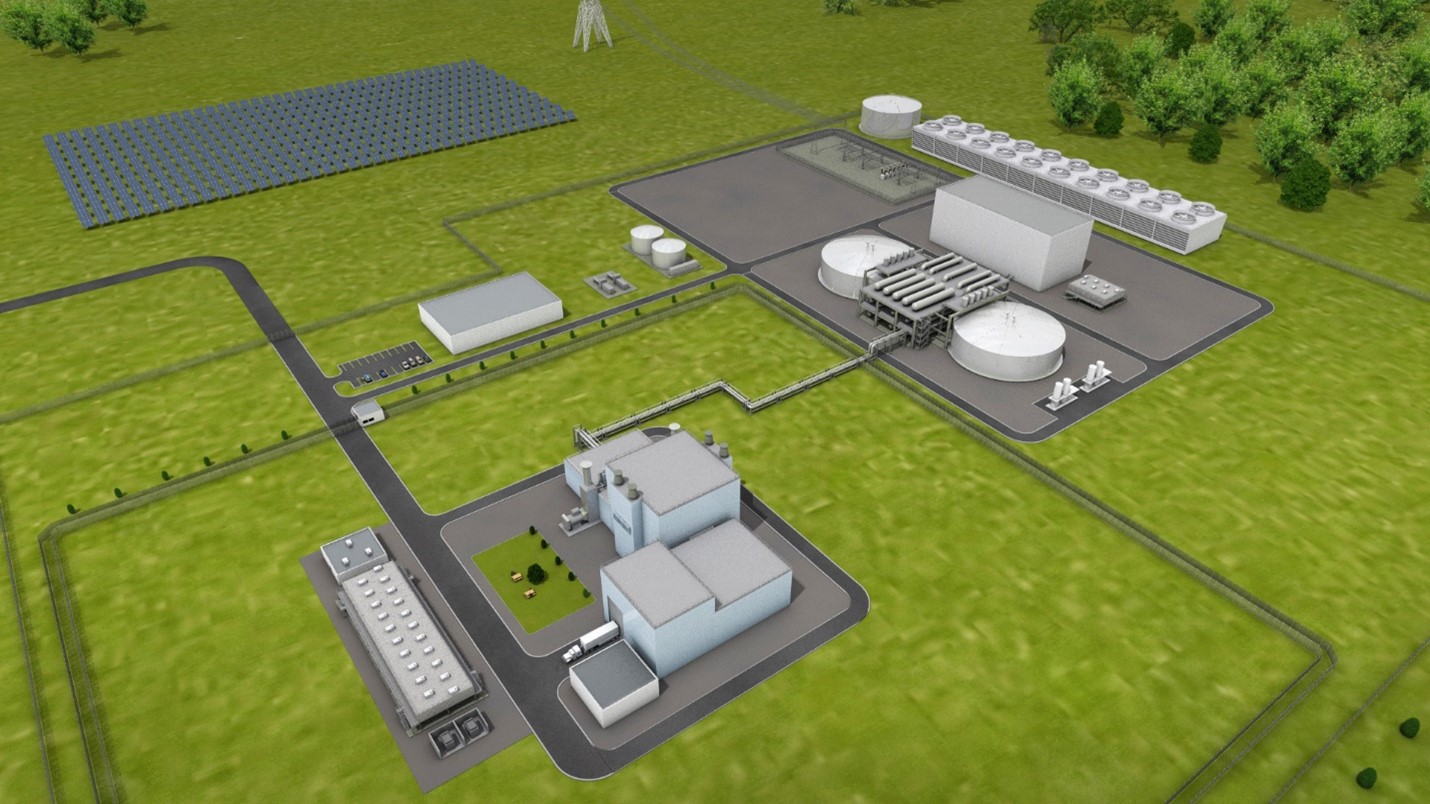

An artist’s rendering of Natrium. (Image: TerraPower)

Advanced nuclear technology firm TerraPower announced today the selection of four suppliers to support its Natrium reactor demonstration project, in development near a retiring coal plant in Kemmerer, Wyo.

December 2, 2022, 3:03PMNuclear NewsBrian Dassatti, Kamila Blain, and Jenn Sinkiewicz Teledyne FLIR PackBot® conducts visual inspections in a hazardous area.

Mobile unmanned systems, also known as MUS, encompass a range of robotic devices, including drones, ground vehicles, crawlers, and submersibles. They are used for a wide range of industrial and defense applications to automate operations and assist humans or completely remove human workers from hazardous conditions. Robotics are ubiquitous in industrial manufacturing. Military robots are routinely employed in combat support applications, such as reconnaissance, inspection, explosive ordnance disposal, and transportation. Drones are used in many industries for security and monitoring, to conduct aerial inspections or surveys, and to capture digital twins. Wind and solar farms use MUS technologies for day-to-day operations and maintenance.

John Wagner, director of Idaho National Laboratory and president of Batelle Energy Alliance, delivered the keynote address at the 26th Annual Nuclear Generator & Supplier Executive Summit. (Photo: USA)

The 26th Annual Nuclear Generator and Supplier Executive Summit, hosted by Utilities Service Alliance (USA), was held at the Coeur d’Alene Golf and Spa Resort in Idaho from June 28 through July 1. About 375 attendees were present for this year’s meeting, themed “Nuclear’s Next Wave” which featured presentations and discussions on emerging nuclear technologies and designs, as well as an integrated tradeshow with about 50 industry suppliers exhibiting products, services, and ideas.

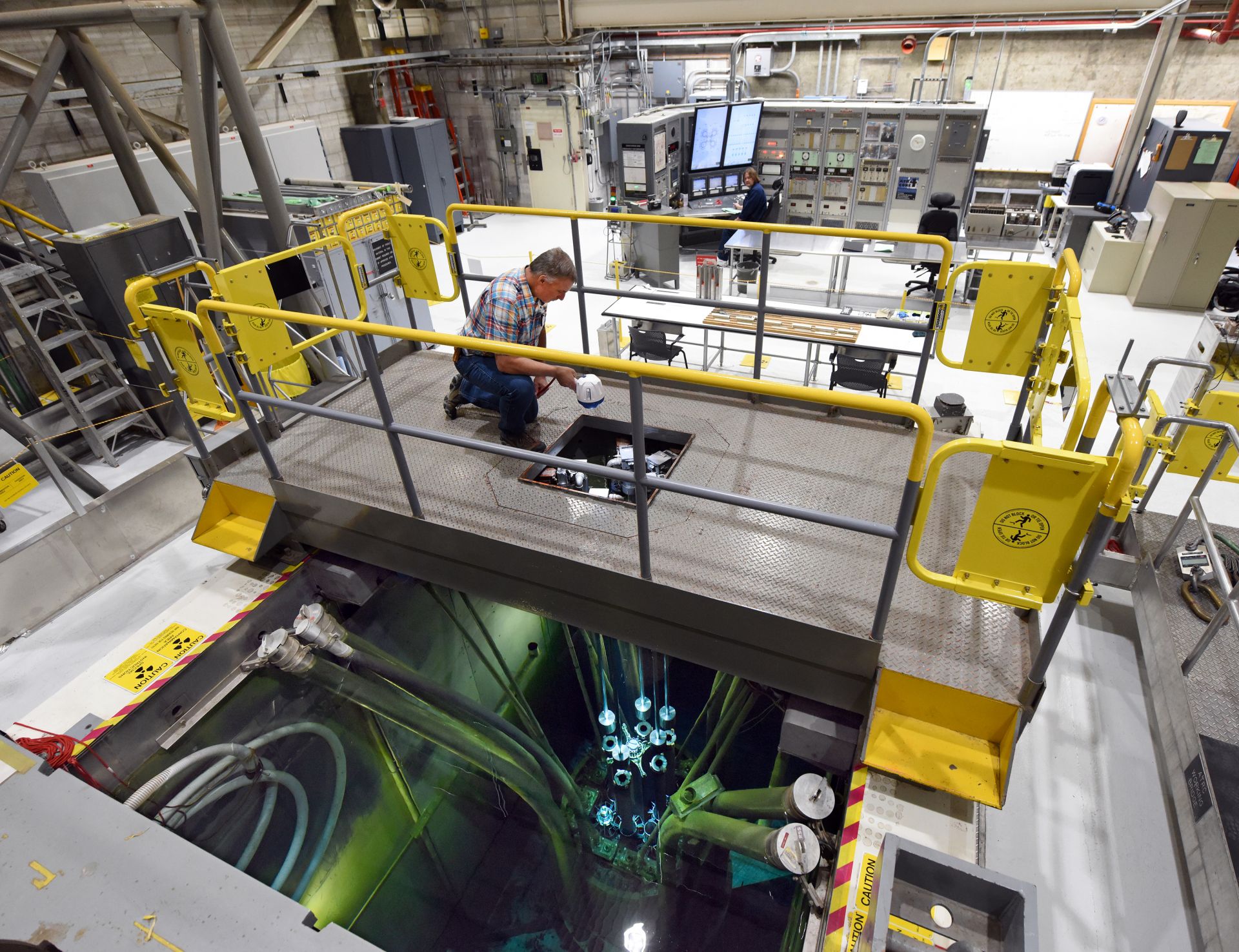

Idaho’s ATR Critical Facility undergoes a digital control system upgrade.

Reactor operators Craig Winder (foreground) and Clint Weigel prepare to start up the ATRC Facility reactor at Idaho National Laboratory after a nearly two-year project to digitally upgrade many of the reactor’s key instrumentation and control systems.

Photos: DOE/INL

At first glance, the Advanced Test Reactor Critical (ATRC) Facility has very little in common with a full-size 800- or 1,000-MW nuclear power reactor. The similarities are there, however, as are the lessons to be learned from efforts to modernize the instrumentation and control systems that make them valuable assets, far beyond what their designers had envisioned.

One of four research and test reactors at Idaho National Laboratory, the ATRC is a low-power critical facility that directly supports the operations of INL’s 250-MW Advanced Test Reactor (ATR). Located in the same building, the ATR and the ATRC share the canal used for storing fuel and experiment assemblies between operating cycles.

.png)