Argonne director Paul Kearns, undersecretary of state for arms control and international security Bonnie Jenkins, EPRI chief nuclear strategy officer Neil Wilmshurst, and DOE acting assistant secretary for nuclear energy Michael Goff spoke at COP29 in Baku, Azerbaijan. (Photo: PNNL/Nazar Kholod)

Argonne National Laboratory will play a leading role in planning and rebuilding a nuclear-generated clean energy infrastructure for postwar Ukraine as part of the lab’s focus on developing small modular reactor applications to help countries meet energy security goals. The latest plans, described in a November 19 article, were announced on November 16 at COP29 in Baku, Azerbaijan.

At INL's Fuel Conditioning Facility, spent nuclear fuel material is being recycled into fuel for Oklo's commercial Aurora Powerhouse deployment at INL. (Photo: INL)

Oklo Inc. announced yesterday that a safety design report for the Aurora fuel fabrication facility the company plans to build at Idaho National Laboratory has the approval of the Department of Energy. At the facility, Oklo plans to use high-assay low-enriched uranium (HALEU) that has been recovered from used Experimental Breeder Reactor-II fuel to produce fuel for its first planned microreactor—dubbed Aurora—which is also set for deployment at INL.

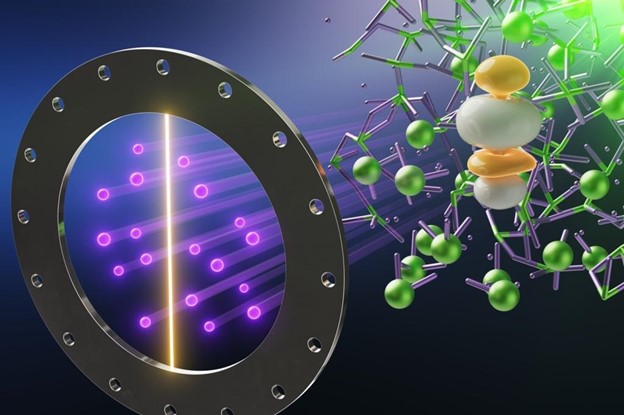

In this illustration of oscillating UCl3 bonds, neutrons produced at the SNS (purple dots) scatter off molten UCl3 (depicted in green), revealing its atomic structure. Yellow and white shapes simulate data and represent the oscillating UCl3 bonds. (Image: Alex Ivanov/ORNL)

New research into the dynamics and structure of high-temperature liquid uranium trichloride (UCl3) salt—a potential fuel for molten salt reactors—has been published in the Journal of the American Chemical Society. A recent news release from Oak Ridge National Laboratory describes how researchers from ORNL, Argonne National Laboratory, and the University of South Carolina used ORNL’s Spallation Neutron Source (SNS) to document the unique chemistry of liquid UCl3 “for the first time.”

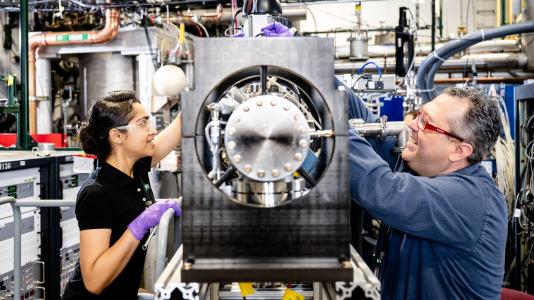

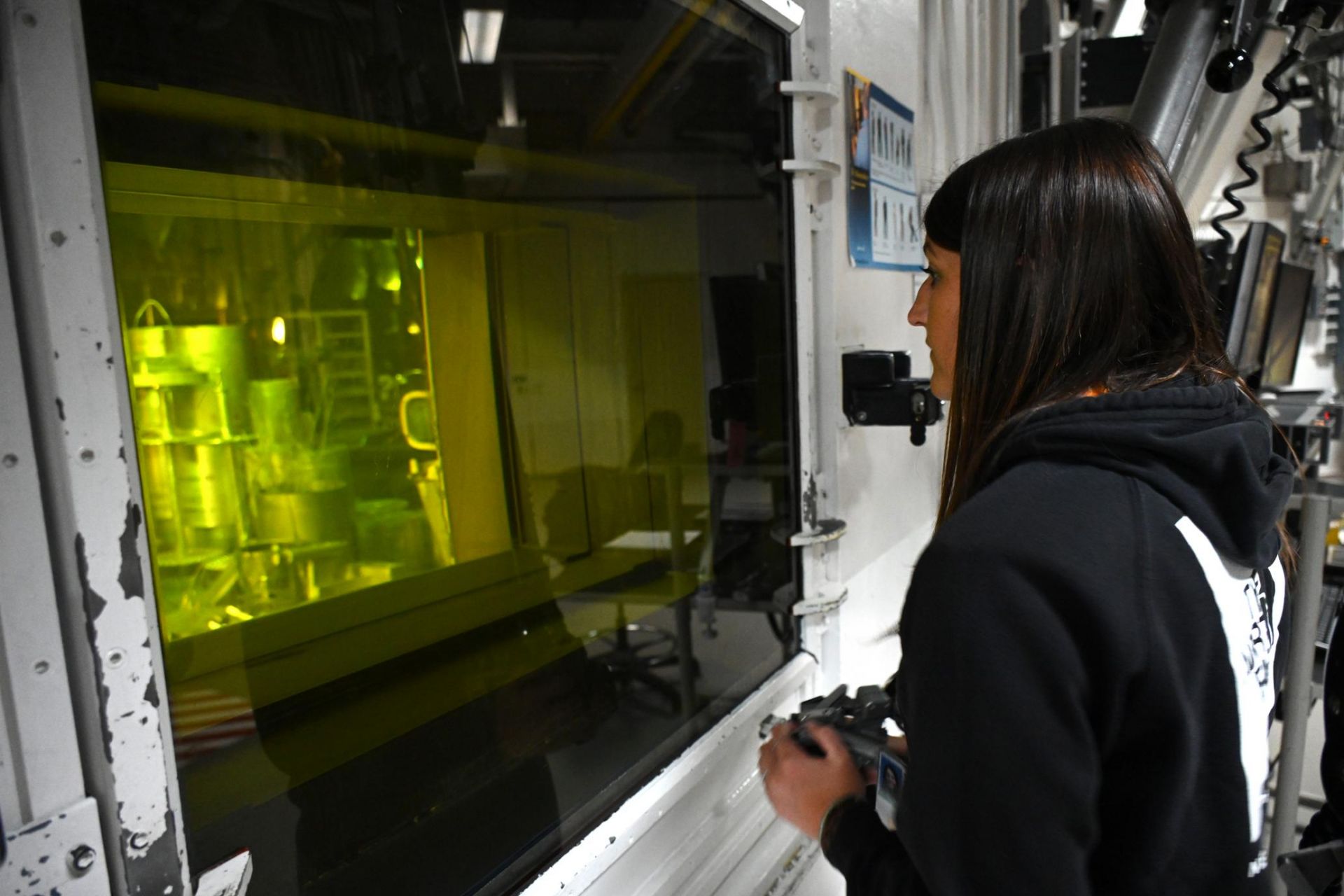

Matthew Jasica is a member of a small team conducting large-scale experimental testing of reactors and their components at the NSTF. (Photo: Argonne)

A facility at Argonne National Laboratory has been simulating nuclear reactor cooling systems under a wide range of conditions since the 1980s. Its latest task, described by Argonne in an August 13 news release, is testing the performance of passive safety systems for new reactor designs.

Designed as a half-scale model of a real reactor system, Argonne’s Natural Convection Shutdown Heat Removal Test Facility (NSTF) is used for large-scale experimental testing of the performance of passive safety systems, which are designed to remove decay heat using natural forces including gravity and heat convection. Those tests yield benchmarking data qualified to the level of National Quality Assurance-1 (NQA-1) that is shared with vendors and regulators to validate computational models and guide licensing of new reactors and components.

The ALCF AI Testbed includes the AI systems represented in this collage: Cerebras, Graphcore, Groq, and SambaNova. (Image: Argonne National Laboratory)

Generative artificial intelligence paired with advanced diagnostic tools could detect potential problems in nuclear power plants and deliver a straightforward explanation to operators in real time. That’s the premise of research out of the Department of Energy’s Argonne National Laboratory, and just one example of the DOE’s increasing exploration of AI applications in nuclear science and technology research. Training and restraining novel AI systems take expertise and data, and the DOE has access to both. According to a flurry of reports and announcements in recent months, the DOE is setting out its plans to ensure the United States can use AI to its advantage to enhance energy security and national security.

Engineers in Argonne’s Chemical and Fuel Cycle Technologies Division. (Photo: Argonne National Laboratory)

Oklo Inc. announced that it has completed the first end-to-end demonstration of its advanced fuel recycling process as part of an ongoing $5 million project in collaboration with Argonne and Idaho National Laboratories. Oklo’s goal: scaling up its fuel recycling capabilities to deploy a commercial-scale recycling facility that would increase advanced reactor fuel supplies and enhance fuel cost effectiveness for its planned sodium fast reactors.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

Researchers at the Department of Energy’s Argonne National Laboratory are investigating the details of plutonium chemistry with the goal of aiding the cleanup of the Hanford Site in Washington state. For more than 40 years, reactors located at Hanford produced plutonium for America’s defense program, resulting in millions of gallons of liquid radioactive and chemical waste.

Argonne scientists adjust the AMIS beamline prior to its commissioning. (Photo: Argonne)

Argonne’s newest beamline uses heavy ions to degrade a material’s properties as much in a day as a nuclear reactor does in a year, without introducing radioactivity. That’s according to an article published January 16 by Argonne National Laboratory. The Argonne Tandem Linac Accelerator System (ATLAS) now boasts a new beamline—the ATLAS Material Irradiation Station, or AMIS—that uses the accelerator’s lowest high-energy beams to displace atoms and mimic the degradation of materials inside an operating reactor over time. AMIS makes it easier and faster to test candidate fuel and structural materials for existing and future reactors.

A Framatome operator fabricates U-Mo foils at CERCA. (Photo: Framatome)

Framatome is prepared to manufacture a novel molybdenum-uranium (U-Mo) fuel to extend the life and safe operation of the Forschungsreaktor München II (FRM II) research reactor in Germany. A new fuel supply—one that uses uranium enriched to less than 20 percent U-235—means the FRM II can continue to supply neutrons to industry and the scientific community. The fuel is “Europe’s low-enriched fuel with the highest density ever realized for research reactor operations,” according to Framatome’s April 27 announcement.

Researchers are looking for the ideal characteristics of molten salt, which can serve as both coolant and fuel in advanced nuclear reactors. (Photo: Argonne National Laboratory)

Scientists are searching for new materials to advance the next generation of nuclear power plants. In a recent study, researchers at the Department of Energy’s Argonne National Laboratory showed how artificial intelligence could help pinpoint the right types of molten salts, a key component for advanced nuclear reactors.

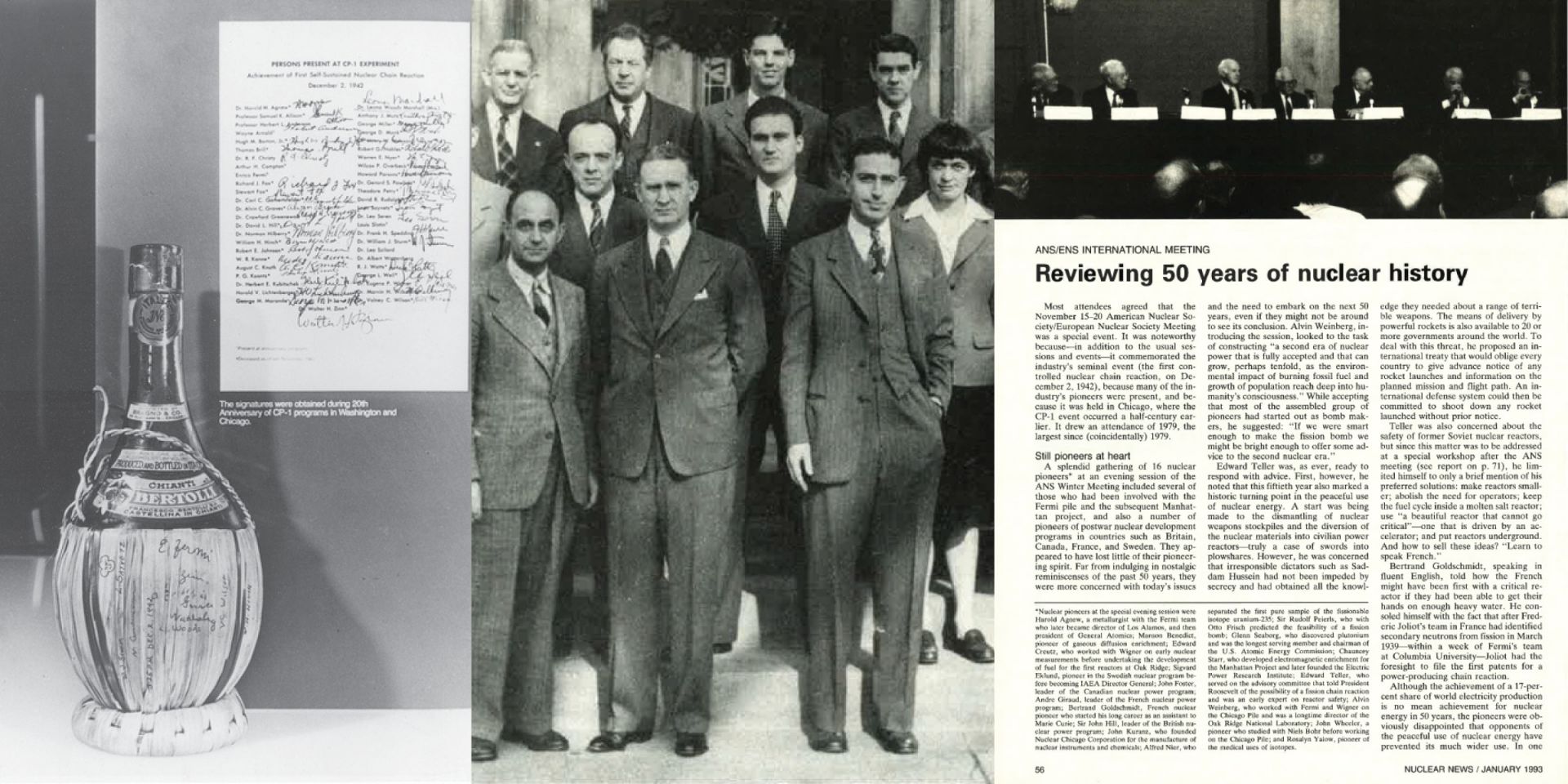

A replica of the chianti bottle signed by many of those present on December 2, 1942, alongside the image of a document signed 20 years later by most of those present (Photo: ANL); a portion of a photo of CP-1 scientists taken on December 2, 1946 (Photo: ANL); January 1993 Nuclear News coverage of CP-1 50th anniversary commemorations during the 1992 ANS Winter Meeting.

Nuclear Newswire is back with the final #ThrowbackThursday post honoring the 80th anniversary of Chicago Pile-1 with offerings from past issues of Nuclear News. On November 17, we took a look at the lead-up to the first controlled nuclear chain reaction and on December 1, the events of December 2, 1942, the day a self-sustaining nuclear fission reaction was created and controlled inside a pile of graphite and uranium assembled on a squash court at the University of Chicago’s Stagg Field.

U.S. special envoy for climate John Kerry at COP27. (Photo: Embassy of Ukraine in the United States of America)

U.S. special envoy for climate John Kerry and Ukraine’s minister of energy German Galushchenko have announced a two-to-three-year pilot project aimed at demonstrating the commercial-scale production of clean hydrogen and ammonia from small modular reactors in Ukraine using solid oxide electrolysis.

Alkali-silica reaction was confirmed at the Seabrook nuclear power plant in 2010. (Photo: NextEra Energy Resources)

Concrete structures built to last for decades, including reactor containment buildings and other nuclear power plant structures, are subject to the alkali-silica reaction (ASR), a reaction between alkali ions found in cement and silica, the two main components of concrete. The reaction forms a gel that absorbs water and expands over time, causing a buildup of pressure within the concrete that can eventually lead to cracking and deterioration.

Researchers at Argonne National Laboratory have successfully used electrochemical impedance spectroscopy (EIS) to detect ASR in the lab and believe it could be used for cost-effective, nondestructive testing at nuclear power plants.

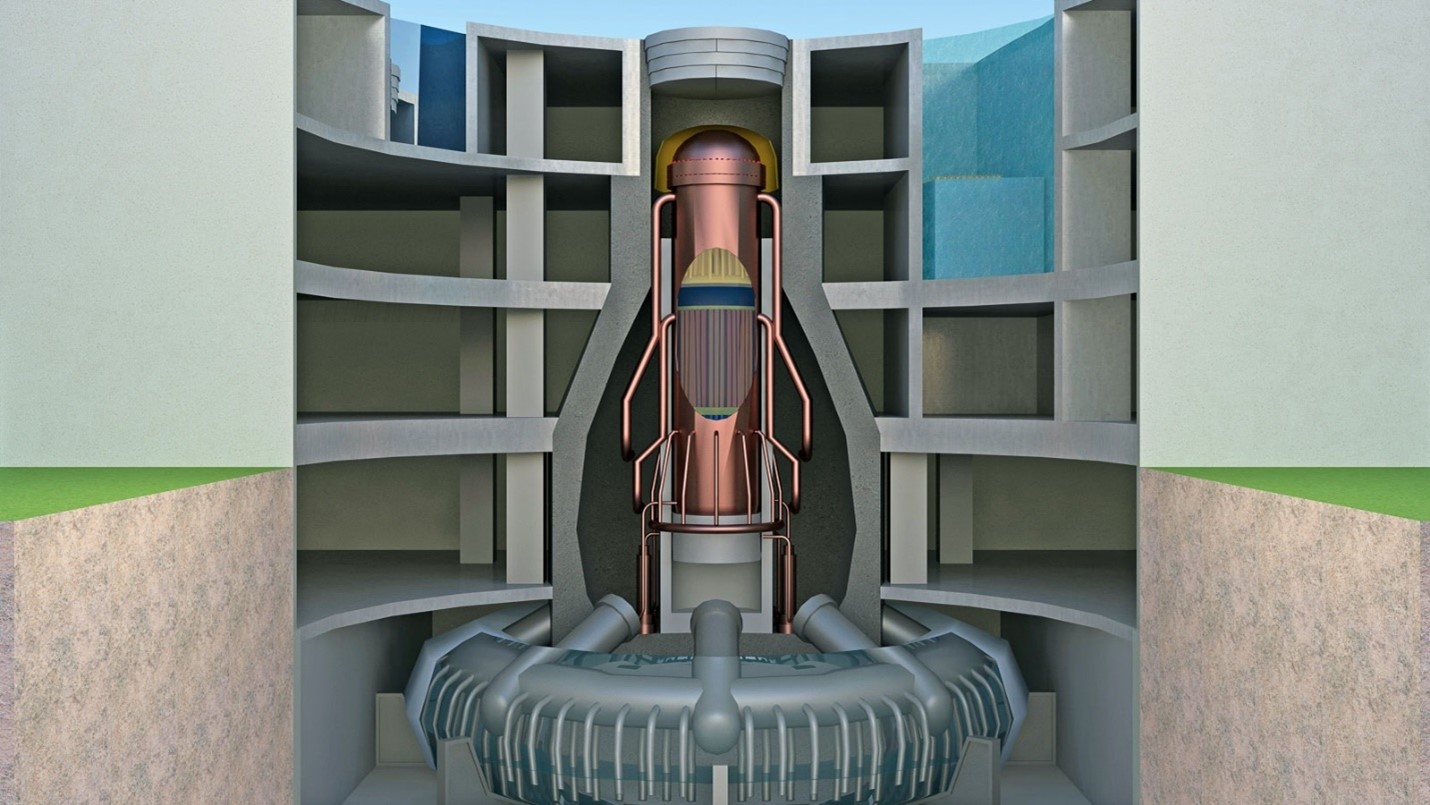

A cutaway view of a nuclear reactor. Its construction consists of two essential material types: fuel, which comprises the rods and cores that hold the fuel (center vertical bands); and structural, those parts of the reactor that house the fuel materials. (Graphic: Shutterstock/petrov-k)

Researchers from the Department of Energy’s Argonne National Laboratory are developing a “tool kit” based on artificial intelligence that will help better determine the properties of materials used in building a nuclear reactor.

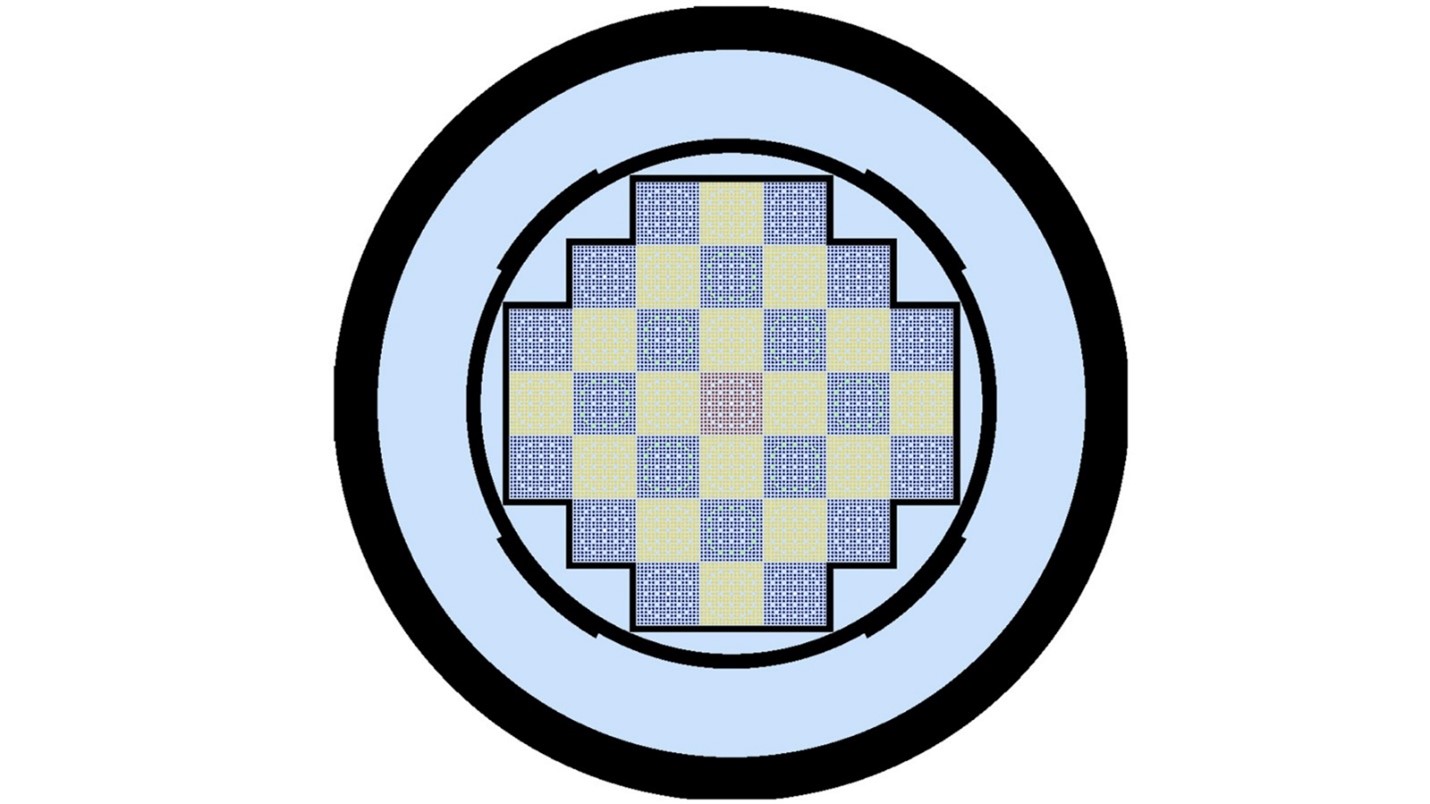

This image shows the individual pins in a full-core nuclear reactor simulation. (Image: ANL)

Coolant flow around the fuel pins in a light water reactor core plays a critical role in determining the reactor’s performance. For yet-to-be-built small modular reactors, a thorough understanding of coolant flow will be key to successfully designing, building, and licensing first-of-a-kind reactors.

.png)