Rethinking seismic design may be key for making nuclear plant construction affordable.

Nuclear power plants not only provide the nation’s largest source of carbon-free electricity, they also can operate 24 hours a day, 365 days a year to augment intermittent renewables such as wind and solar. Further, studies show that nuclear energy is among the safest forms of energy production, especially when considering factors such as industrial accidents and disease associated with fossil fuel emissions. All said, nuclear has the potential to play a key role in the world’s energy future. Before nuclear can realize that potential, however, researchers and industry must overcome one big challenge: cost.

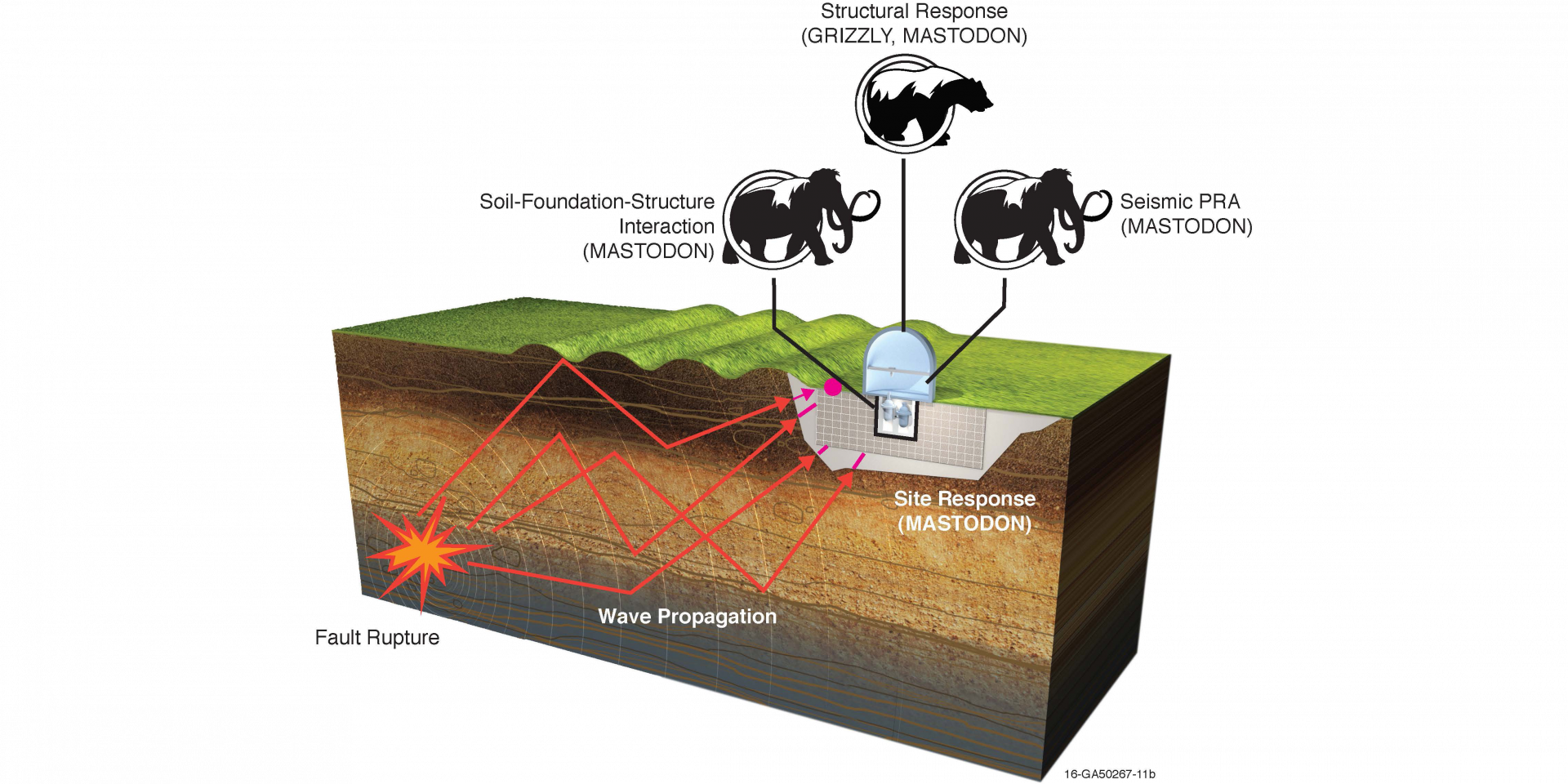

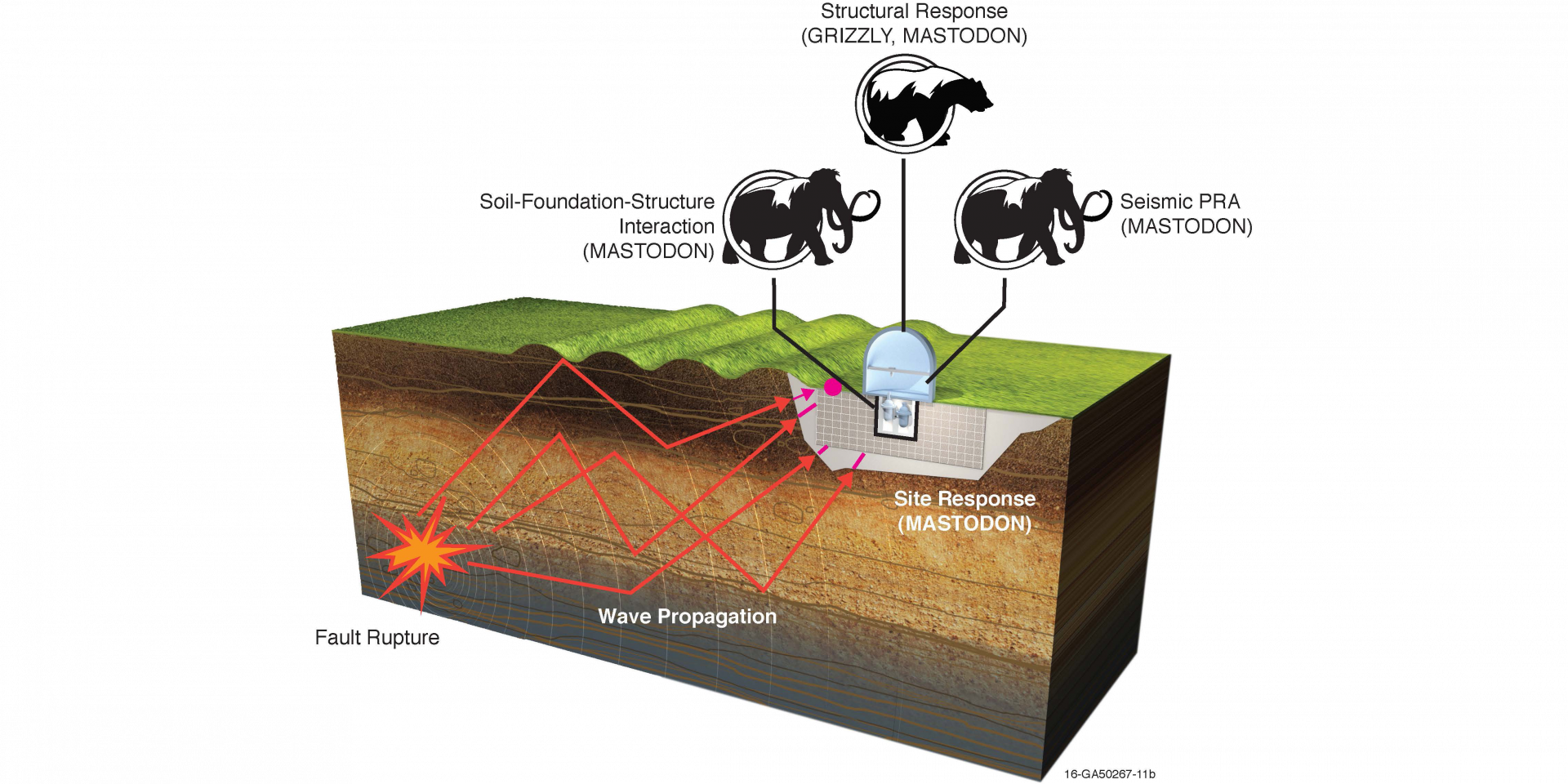

A team at Idaho National Laboratory is collaborating with experts around the nation to tackle a major piece of the infrastructure equation: earthquake resilience. INL’s Facility Risk Group is taking a multipronged approach to reduce the amount of concrete, rebar, and other infrastructure needed to improve the seismic safety of advanced reactors while also substantially reducing capital costs. The effort is part of a collaboration between INL, industry, the Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E), and the State University of New York–Buffalo (SUNY Buffalo).

Sen Joe Manchin gives his opening statement at the March 25 hearing.

The Senate Energy and Natural Resources Committee yesterday held a hearing to examine the latest developments in the U.S. nuclear energy sector, with a focus on ways to maintain and expand the use of nuclear in the United States and abroad.

Testifying before the committee were Jeffrey Lyash, president and chief executive officer of the Tennessee Valley Authority (TVA); Chris Levesque, president and CEO of TerraPower, Scott Melbye, president of Uranium Producers of America (UPA); Amy Roma, founding member of the Atlantic Council’s Nuclear Energy and National Security Coalition and a partner with the law firm Hogan Lovells; and J. Clay Sell, CEO of X-energy.

Demolition begins on the six-story, 255,000-square-foot Building 9207, the final building in the former Biology Complex at Oak Ridge. Photo: DOE

Workers with the Department of Energy’s Office of Environmental Management (EM) recently began demolishing the last facility standing in the former Biology Complex at the Y-12 National Security Complex at the Oak Ridge Reservation in Tennessee.

As announced by EM on March 23, removal of the massive six-story, 255,000-square-foot Building 9207 creates a new chapter of transformation and modernization for Y-12. Completion of the Biology Complex demolition is one of EM’s 2021 priorities.

According to EM, the facilities in the Biology Complex presented significant structural risks due to their deterioration, and their condition landed them on DOE’s list of high-risk excess contaminated facilities.

The Three Mile Island nuclear generating station in 2010.

A community advisory board has been formed for the decommissioning of Unit 2 of the Three Mile Island nuclear power plant, according to a March 23 report by StateImpact Pennsylvania, a collaboration of National Public Radio member stations. The Nuclear Regulatory Commission approved in December the transfer of TMI-2 and its license to TMI-2 Solutions for decommissioning. TMI-2 Solutions is a subsidiary of EnergySolutions.

According to the report, the TMI-2 Community Advisory Panel (CAP) is made up of 15 people who represent the plant and its neighbors, including townships, school districts, first responders, nuclear planners, and state historians. The group is being led by Londonderry Township manager Steve Letavic.

TMI-2 Solutions said that it will provide quarterly decommissioning updates to the TMI-2 CAP. As a volunteer non-regulatory organization, the CAP will provide community feedback to TMI-2 Solutions, including any issues or concerns related to TMI-2 decommissioning activities.

Savannah River’s DWPF has been pouring high-level waste canisters for a quarter of a century. Photo: DOE

The month of March marked the 25th year of radiological operations for the Defense Waste Processing Facility (DWPF) at the Department of Energy’s Savannah River Site in South Carolina. Radiological operations at DWPF, which is used to treat Savannah River’s high-level radioactive tank waste, began on March 12, 1996, with the first canister of vitrified waste poured on April 29 that year.

To date, more than 4,200 stainless steel canisters of vitrified waste have been poured at DWPF, according to the DOE.

The only operating waste vitrification plant in the nation, DWPF is operated by Savannah River Remediation, the DOE’s liquid waste contractor at the site. According to the DOE, DWPF operations are expected to continue for approximately 15 more years, and about 4,000 more canisters are scheduled to be produced. The DOE expects to begin hot operations at a second waste vitrification plant later this year at its Idaho National Laboratory site.

The first wall section of Saltstone Disposal Unit 8 is being constructed at the Savannah River Site. Source: DOE

The first wall section of Saltstone Disposal Unit 8 (SDU 8) at the Department of Energy's Savannah River Site in South Carolina was installed earlier this month.

SDU 8 will stand 43 feet tall and 375 feet in diameter, and have a 33-million-gallon capacity, just like two SDUs built recently at the site. The 25 wall sections of SDU 8 are being constructed using high-strength, reinforced concrete and will be wrapped with seven layers of more than 300 miles of steel cable for added strength.

The flooring of SDU 8 is more than halfway complete. The concrete floor sits on top of a multilayer foundation: a geosynthetic clay liner and high-density plastic liner sandwiched between two concrete layers called “mud mats.” The floor is being completed in 14 sections.

The disposal units are built to safely and permanently contain decontaminated salt solution processed at Savannah River, the DOE reported on March 9.

The Gateway for Accelerated Innovation in Nuclear (GAIN) announced that three nuclear technology companies—Radiant, Oklo, and Lightbridge—will receive GAIN nuclear energy vouchers to accelerate the innovation and application of advanced nuclear technologies.

The Gateway for Accelerated Innovation in Nuclear (GAIN) announced that three nuclear technology companies—Radiant, Oklo, and Lightbridge—will receive GAIN nuclear energy vouchers to accelerate the innovation and application of advanced nuclear technologies.