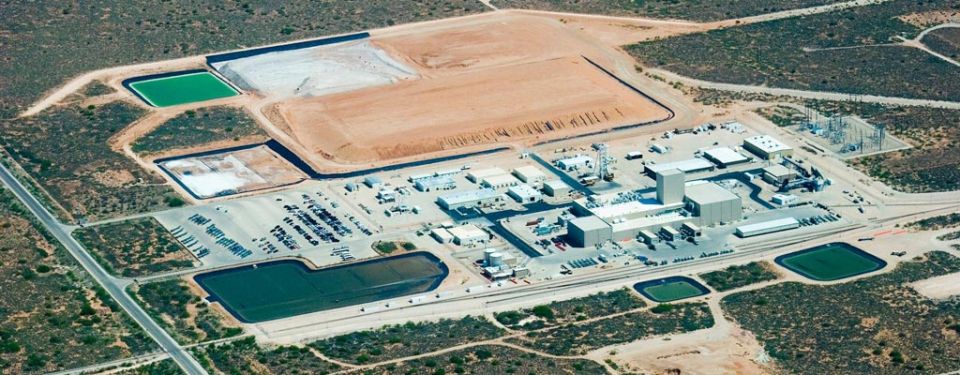

An aerial view of the Hanford Site’s 200 Area and the Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: DOE)

The U.S. Department of Energy, Washington State Department of Ecology, and U.S. Environmental Protection Agency have reached an agreement on revised plans for managing millions of gallons of radioactive and chemical liquid waste stored in 177 underground tanks at the Hanford Site near Richland, Wash.

Data from Fukushima ALPS-treated water discharge. (Image: IAEA)

An International Atomic Energy Agency task force has confirmed that the discharge of treated water from Japan's Fukushima Daiichi nuclear power plant is progressing in accordance with the plan approved by Japan’s Nuclear Regulation Authority.

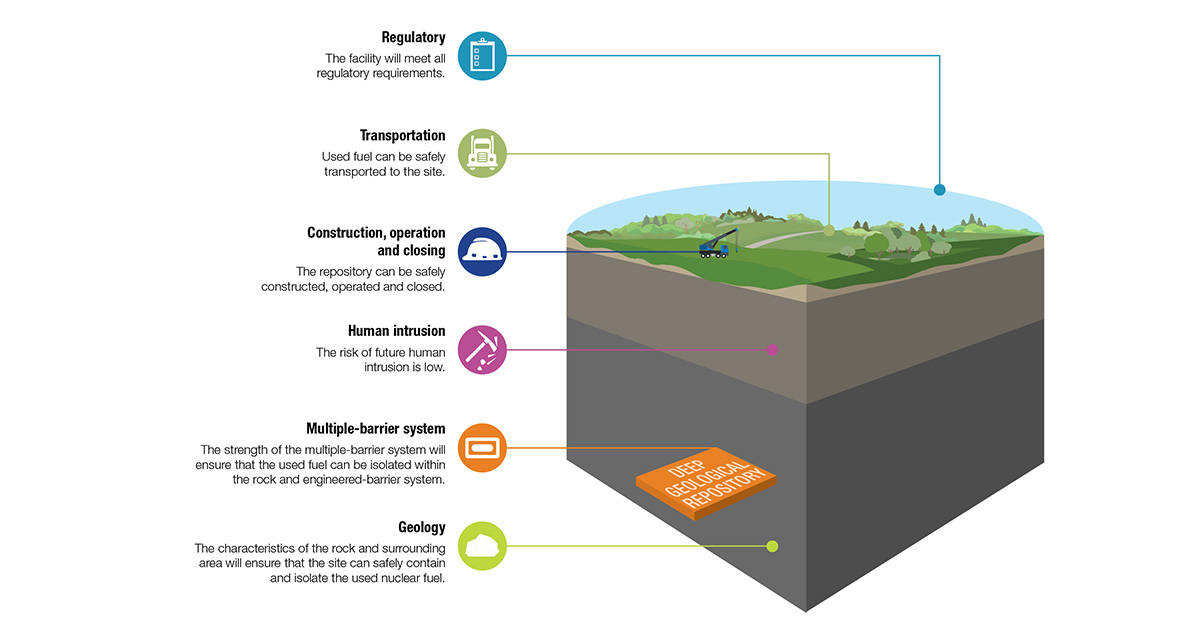

An illustration of a planned deep geologic repository for Canada’s spent nuclear fuel. (Image: NWMO)

Canada’s Nuclear Waste Management Organization, a not-for-profit organization responsible for the long-term management of the country’s intermediate- and high-level radioactive waste, is set to select a site for a deep geologic repository by the end of the year.

A view of the Waste Isolation Pilot Plant in New Mexico. (Photo: DOE)

Harrison Western Shaft Sinkers (HWSS), the company drilling a new utility shaft at the Department of Energy’s Waste Isolation Pilot Plant in New Mexico, has retained a safety culture expert following a near-miss accident in the shaft late last year. The safety expert will conduct monthly facilitated discussions with crews working on the shaft to reinforce expectations for identifying concerns regarding unsafe circumstances, according to a recent report by the Defense Nuclear Facilities Safety Board (DNFSB).

SDU 9 is the latest megavolume disposal unit completed at SRS. (Photo: DOE)

The Waste Isolation Pilot Plant, near Carlsbad, N.M. (Photo: DOE)

The Department of Energy’s Office of Environmental Management has issued a request for qualifications for interested parties and prospective offerors looking to enter into a realty agreement for carbon-pollution-free electricity (CFE) projects at the department’s Waste Isolation Pilot Plant site in southeastern New Mexico.

An artistic representation of a Desulfosporosinus cell with immobilized uranium on the surface. (Image: B. Schröder/HZDR)

Researchers at the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) research laboratory in Germany have investigated a microorganism capable of transforming water-soluble hexavalent uranium [U(VI)] to the less-mobile tetravalent uranium [U(IV)]. The researchers found that the sulfate-reducing bacterium Desulfosporosinus hippei, a relative of naturally occurring microorganisms present in clay rock and bentonite, showed a relatively fast removal of uranium from clay pore water.

Vit Plant crews begin adding frit into Hanford’s second melter. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management recently announced that crews at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, recently brought the second of two 300-ton melters up to the operating temperature of 2,100°F.

The DOE’s Argonne National Laboratory in Lemont, Ill. (Photo: DOE)

Researchers at the Department of Energy’s Argonne National Laboratory are developing and deploying ARG-US (from the Greek Argus, meaning “Watchful Guardian”) remote monitoring systems technologies to enhance the safety, security, and safeguards (3S) of packages of nuclear and other radioactive material during storage, transportation, and disposal.

As part of its DUF6 conversion program, the DOE is shipping converted depleted uranium oxide to WCS for disposal.

The first major shipment of depleted uranium oxide for disposal departs the DOE’s Paducah Site in Kentucky in early 2023 for disposal at the WCS facility in Texas.

Last year in late August, 120 storage cylinders of depleted uranium oxide (DUOx) safely arrived by rail in West Texas, having been shipped from the Department of Energy’s Portsmouth Site in Ohio. It was the first such shipment of the stable crystalline powder from the Portsmouth Site and was another milestone in the DOE Office of Environmental Management’s (EM) efforts to ship DUOx for off-site disposal.

Upgrades are under way at the Hanford Site's 222-S Laboratory, including replacing the Cold War-era windows in the labs hot cells. Photo: DOE)

A screen shot of a video marking the 25th anniversary of operations at the WIPP disposal facility. (Image: DOE)

The Department of Energy’s Office of Environmental Management celebrated a major milestone for the Waste Isolation Pilot Plant last week, marking the 25th anniversary of the receipt of the first waste shipment at the disposal facility in New Mexico’s Chihuahuan Desert.

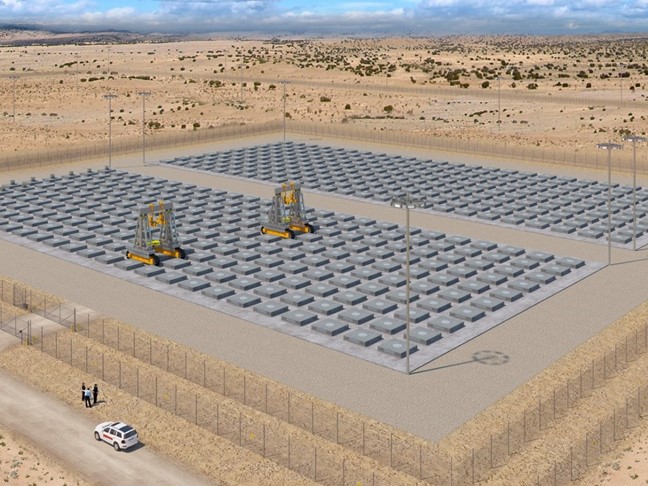

Concept art of Holtec’s proposed HI-STORE CISF in New Mexico. (Image: Holtec)

The 5th Circuit Court of Appeals has vacated Holtec International’s license to build and operate a consolidated interim storage facility (CISF) for spent nuclear fuel near the Waste Isolation Pilot Plant in southeastern New Mexico. The Nuclear Regulatory Commission granted the license for the Holtec facility, called the HI-STORE CISF in May 2023.

SRS successfully made the first transfer of decontaminated salt solution directly from one waste processing facility to the other, bypassing a hold tank previously used in the transfer process. (Photo: DOE)

The Department of Energy Office of Environmental Management’s liquid waste contractor at the Savannah River Site this month marked the first direct transfer of decontaminated waste from the Salt Waste Processing Facility (SWPF) to the Saltstone Production Facility (SPF). This is a new step in optimizing waste processing, according to the DOE.