YouTube influencer’s amorous affair with nuclear

On this holiday that celebrates all things love, here’s a look at the love affair that Kyle Hill has with nuclear energy—even its waste.

On this holiday that celebrates all things love, here’s a look at the love affair that Kyle Hill has with nuclear energy—even its waste.

The Department of Energy Office of Environmental Management’s Office of River Protection and contractor Washington River Protection Solutions have completed the first waste processing campaign through the Tank-Side Cesium Removal (TSCR) system at the Hanford Site.

The Department of Energy’s Office of Environmental Management announced last week that, for calendar year 2023, the department’s Waste Isolation Pilot Plant (WIPP) had its best shipment performance in 10 years, having received 489 transuranic (TRU) waste shipments from generator sites throughout the country. For comparison, WIPP received only 272 shipments in 2022.

Nukem Technologies, a German-based radioactive waste management company, announced last week that it has successfully completed a mock-up for a state-of-the-art waste solidification plant. The plant will use the in-drum cementation process for encapsulating various types of radioactive waste into a solid, secure form suitable for long-term storage.

For the first time in a decade, crews have started mining a new disposal panel at the Department of Energy’s Waste Isolation Pilot Plant (WIPP) in New Mexico, the nation’s deep geologic waste repository for defense-related transuranic waste.

The Roy G. Post Foundation has announced the awarding of more than 50 graduate and undergraduate scholarships for 2024 for outstanding students who have demonstrating excellent academic achievements and leadership qualities and who have made positive impacts in their communities.

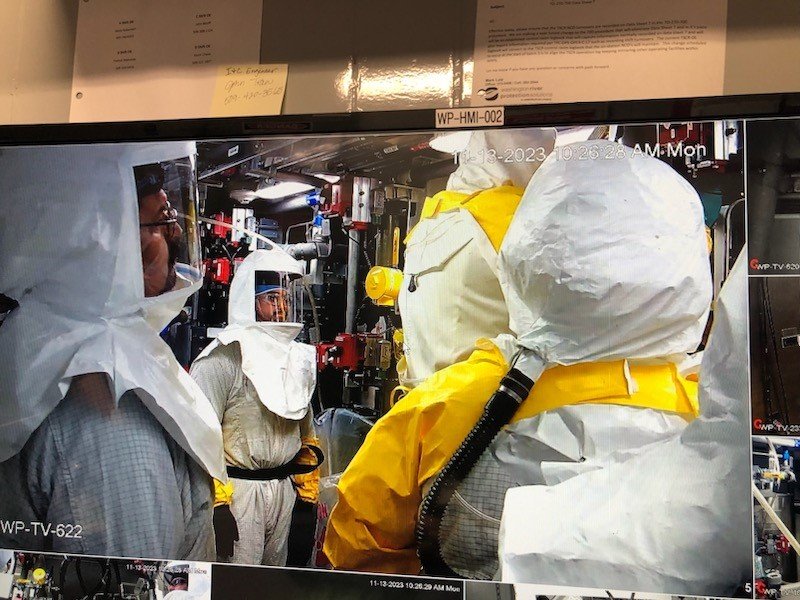

The training team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently added an extra level of realism to employee trainings by upgrading classrooms and adding new props, according to the Department of Energy.

The Canadian Nuclear Safety Commission has decided to amend Canadian Nuclear Laboratories’ operating license for the Chalk River Laboratories, allowing the construction of a near surface disposal facility (NSDF) for low-level radioactive waste on the nuclear research site in Deep River, Ontario.

A vertical cask transporter at Ukraine’s CSFSF. (Photo: Holtec)

Holtec International announced on December 19 that Energoatom, Ukraine’s national nuclear energy company, has begun transporting spent nuclear fuel from the nation’s operating reactors to its newly built and commissioned Central Spent Fuel Storage Facility (CSFSF). The facility is expected to save Ukraine $200 million annually through avoided payment to the Russian Federation for transport and storage to that country.

According to a December 15 report by Interfax, a total of 13 spent fuel containers have already been placed at the CSFSF, which is currently operating under a three-year trial operation permit.

Background: Located inside the Chernobyl Exclusion Zone, the CSFSF is designed for the long-term storage of spent nuclear fuel from the South Ukraine, Khmelnytskyi, and Rivne nuclear power plants.

Holtec, under contract by Energoatom, completed the construction and licensing of the CSFSF in 2021. Transport of spent fuel to the facility was to begin in early 2022 but was delayed by Russia’s invasion of Ukraine.

The Department of Energy’s Office of Environmental Management said Idaho’s Integrated Waste Treatment Unit (IWTU) is set to resume radioactive liquid waste treatment operations early next year after crews replaced carbon material from two plant vessels. The IWTU was shut down for an unplanned outage on September 6 to address elevated mercury concentrations in the plant’s granulated activated carbon (GAC) beds, according to Defense Nuclear Facilities Safety Board (DNFSB) reports.

ANO dry storage campaign professionals stand before Holtec’s 2,000th storage cask. (Photo: Holtec)

Holtec International announced that it successfully loaded its 2,000th spent nuclear fuel canister this fall as part of the ongoing dry storage campaign at Entergy’s Arkansas Nuclear One (ANO) power plant in Russellville, Ark.

Spent fuel from ANO’s two pressurized water reactors is stored in Holtec’s MPC-37 multipurpose canister, each containing 37 PWR fuel assemblies in a prismatic basket made of Holtec’s Metamic-HT material in an egg-crate configuration. The company’s HI-STORM dry fuel storage systems have been in use at ANO since 2003.

Quote: Entergy’s chief nuclear officer, Kimberly Cook-Nelson, said, “We appreciate the strong partnership that we at Entergy have with Holtec. Arkansas Nuclear One is an important facility for our company, the industry, the state of Arkansas, and the Russellville community, and having the 2,000th spent fuel dry storage system is a key milestone for our continued safe, secure, and reliable operations.”

Department of Energy contractor Savannah River Nuclear Solutions (SRNS) said its Savannah River Site employees recently used an innovative method to ensure the integrity of radioactive material storage containers currently in long-term dry storage at the South Carolina site.

Bechtel and the Department of Energy’s Office of Environmental Management announced on December 4 that the first set of test glass was successfully poured into a stainless-steel storage container designed to hold vitrified waste at Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

Personnel from the Department of Energy’s Office of Environmental Management and the National Nuclear Security Administration recently gathered to discuss plans for the upcoming transfer of landlord responsibility for the Savannah River Site in South Carolina.

Commissioning has begun on a new large-scale ventilation system at the Waste Isolation Pilot Plant in New Mexico.

The Safety Significant Confinement Ventilation System (SSCVS) is expected to increase underground airflow from 170,000 cubic feet per minute up to 540,000 cfm. The increased airflow will allow for simultaneous underground waste emplacement, mining, and ground control work. Ground control, including bolting, controls the movement of salt rock—known as salt creep—in the WIPP underground.

Dear Nevada,

I hope you are doing well. We haven’t talked in a long time. I know you’ve moved on. But you know it’s been harder for me to do that.

Look, I’m sorry. I was forceful at times, and I know that made you feel trapped and caused you to question our relationship—pretty much from the beginning. But you also said some mean and untrue things about me. Your family still HATES me, which stinks, because we have a lot of history together.

Anyhow, just wanted to let you know that, while I might always hold out hope for a chance encounter with you that rekindles that old spark—and I will never part with our memory box—I am finally ready to move on to the next chapter of my life, and I understand that means letting go of you.

Patrick O’Brien

As someone who grew up in a community with an operating nuclear plant—Pilgrim Nuclear Power Station, in Plymouth, Mass., on Cape Cod Bay—I had the luxury of a more thorough education on what nuclear power was (and what it wasn’t) from an early age. Unfortunately, growing up in the 1980s and ’90s, many of my contemporaries were not as lucky; their education on nuclear power came from The Simpsons.

While it is a show that influenced a generation in many ways, its portrayal of the nuclear industry had no basis in reality. Nuclear workers are among the most professional and highly trained people in the world. The standards by which used fuel and waste are handled and stored are some of the strictest of any industry. I have found, after nearly a decade in the nuclear industry, that the first thing I must help the public, media, and even elected officials understand is that used nuclear fuel is not green goo in a barrel, but a solid pellet stored safely in robust dry storage casks. Providing the facts—the science and technology—is the key to helping people understand a complex industry. Doing so in simple terms can help demystify nuclear power.

The Department of Energy’s Office of Environmental Management is responsible for roughly 90 million gallons of radioactive liquid waste at Idaho National Laboratory, the Hanford Site in Washington state, and the Savannah River Site in South Carolina. About 900,000 gallons of waste are stored at INL, 56 million gallons at Hanford, and roughly 36 million at SRS. A further 400,000 gallons of waste from various operations are being stored at the Oak Ridge Site in Tennessee.

Emily Stein

Sylvia Saltzstein

Over the past 50 years, the use of nuclear energy has avoided approximately 70 gigatons of carbon dioxide emissions globally and 24 gigatons in the United States.1 Although carbon dioxide is not being released into the atmosphere when generating energy from nuclear, the waste this energy form does produce must be managed and permanently isolated away from people and the environment.

Outside my office, there is a display case filled with rock samples from all over the world. It contains a disk of translucent, orange salt from the Waste Isolation Pilot Plant near Carlsbad, N.M.; a core of white-and-bronze gneiss from the site of the future deep geologic repository in Eurajoki, Finland; several angular chunks of fine-grained, gray claystone from the underground research laboratory at Bure, France; and a piece of coarse-grained granite from the underground research tunnel in Daejeon, South Korea.