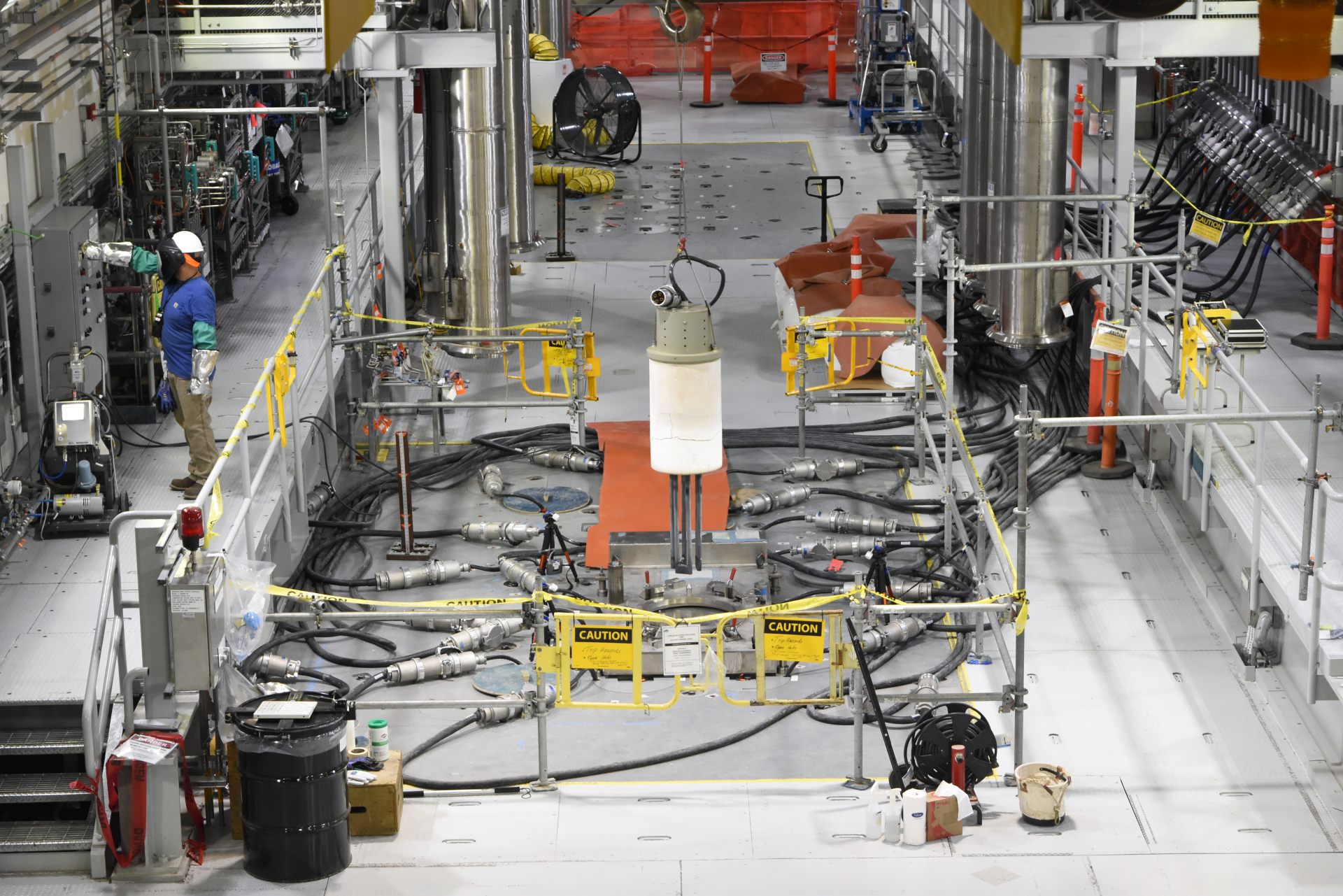

A startup heater is removed from a melter in the Vit Plant’s Low-Activity Waste Facility. (Photo: DOE)

Workers at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, have begun removing the first three of 18 temporary startup heaters, the Department of Energy announced on September 12. The startup heaters were used to raise the first of two 300-ton glass melters in the plant’s Low-Activity Waste Facility to its operating temperature of 2,100°F.

An elk herd at the DOE’s Hanford Site in Washington state. (Photo: DOE)

The Department of Energy has released the first request for information (RFI) related to the department’s Cleanup to Clean Energy initiative, which aims to repurpose certain DOE-owned lands, portions of which were previously used in the nation’s nuclear weapons program, into sites for clean energy generation.

Monticello nuclear power plant. (Photo: Xcel Energy)

The Minnesota Public Utilities Commission (PUC) has approved Xcel Energy’s request for a certificate of need to expand spent fuel storage at the utility’s Monticello nuclear power plant.

The additional storage, according to the PUC, requires installation of a second concrete support pad and modular concrete storage system designed to hold 14 additional steel canisters.

Xcel had requested increased outdoor storage to accommodate its plan to extend Monticello’s operational life by 10 years, to 2040.

Taking part in the Environmental Management Disposal Facility groundbreaking, from left, were Steve Arnette of Jacobs; Mark Whitney of Amentum,; Wade Creswell, a Roane Co., Tenn., executive; Brent Booker of the Laborers’ International Union of North America; Kevin Adkisson of North America’s Building Trades Unions; Jeaneanne Gettle of the EPA; Lt. Gov. Randy McNally; David Salyers of TDEC; Ken Rueter of UCOR; Jay Mullis of OREM; U.S. Rep. Chuck Fleischmann; and DOE-EM’s William “Ike” White. (Photo: DOE)

National, state, and local leaders joined the Department of Energy’s Oak Ridge Office of Environmental Management (OREM) and its lead cleanup contractor, United Cleanup Oak Ridge (UCOR), earlier this month to celebrate the groundbreaking for a new on-site disposal facility at the Oak Ridge Reservation in Tennessee.

Watch a video highlighting the Environmental Management Disposal Facility groundbreaking ceremony here.

Treated water is safer than world standards, essential for decommissioning

Washington, D.C. – The American Nuclear Society (ANS) supports the start of Japan’s controlled release of re-treated, diluted tritium wastewater into the sea from the Fukushima Daiichi Nuclear Power Plant (NPP), which sustained damage in the aftermath of a 2011 earthquake and tsunami.

The Pile Fuel Cladding Silo on the Sellafield site in West Cumbria, England. (Photo: Sellafield Ltd.)

After decades of planning and weeks of preparation and checks, the first batch of legacy waste has been retrieved from the Pile Fuel Cladding Silo at the Sellafield nuclear site in West Cumbria, England. According to Sellafield Ltd., the site license company, a state-of-the-art robotic arm was used to reach into the silo and, for the first time, remove and repackage the waste for longer-term storage.

These retrievals mark a significant achievement in progress toward the cleanup and decommissioning of one of the most hazardous buildings on the site, according to Sellafield Ltd., which made the announcement on August 16.

Watch a video about the Pile Fuel Cladding Silo and Sellafield’s waste retrieval operations here.

An October 2022 photo showing various SDUs at SRS. (Photo: DOE)

The Department of Energy’s Savannah River Site in South Carolina will begin a leak tightness test on what it called “the fourth megavolume saltstone disposal unit (SDU)” at the site.

A schematic illustration of a deep borehole repository assuming disposal into a bedrock. (Image: Sandia National Laboratories via IAEA)

The International Atomic Energy Agency is launching a new Coordinated Research Project (CRP) to increase international knowledge and drive progress toward testing deep borehole disposal for intermediate- and high-level radioactive waste.

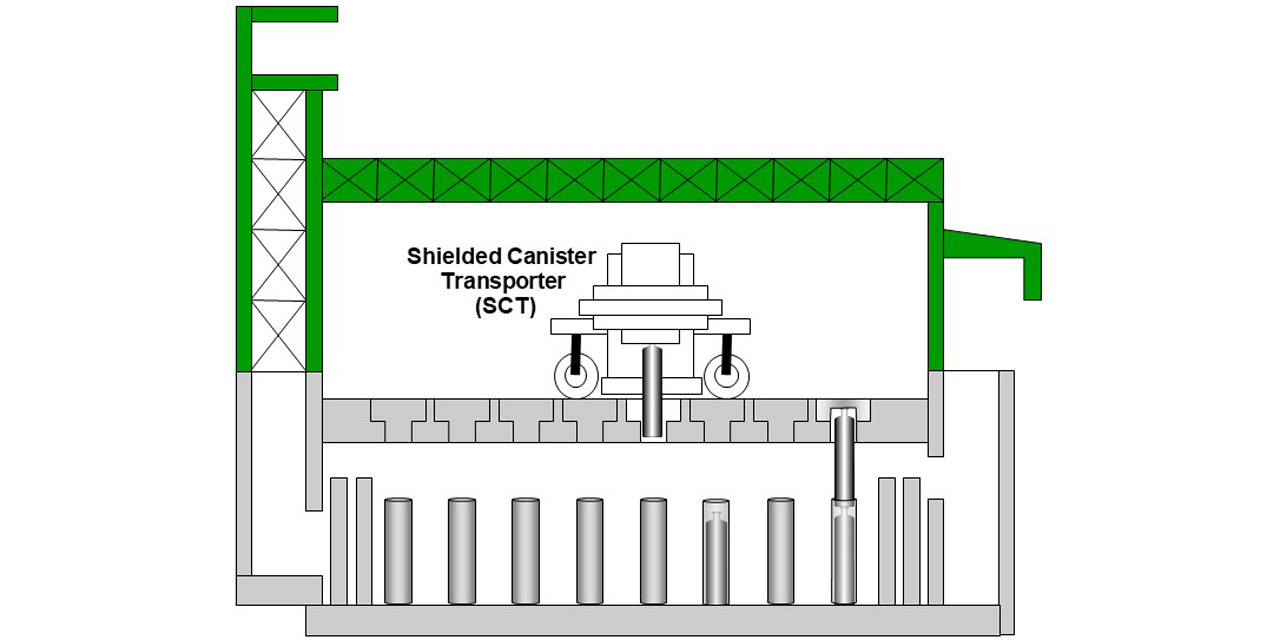

SRS reached a landmark achievement with the placement of 2,000 double-stacked canisters of vitrified HLW. (Image: DOE)

To expand interim storage of vitrified high-level radioactive waste at the Savannah River Site, the Department of Energy’s Office of Environmental Management and its liquid waste contractor Savannah River Mission Completion (SRMC) have double stacked 2,000 canisters in one of the site's two glass waste storage buildings (GWSB). GWSB 1 consists of a below-grade, seismically qualified concrete storage location containing support frames for the vertical storage of 2,262 10-foot-tall canisters.

A 300-pound bag of frit is in position to be poured into the melter at Hanford’s LAW Facility. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management announced that the first batches of glass-forming beads, called frit, were poured last week into a melter at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP), also known as the Vit Plant. The melter, which has been heated to 2,100ºF, will be used to immobilize Hanford’s radioactive and chemical tank waste, turning it into a stable glass form through vitrification.

Some of the participants of the recent SRNL-Hanford Analytical Knowledge Sharing Workshop pause for a photo. (Photo: DOE)

A view of the Low-Activity Waste Facility at the Hanford Site. (Photo: DOE)

The National Academies of Sciences, Engineering and Medicine (NASEM) recently held a public meeting to discuss its third and final report centered on the Department of Energy’s Office of Environmental Management’s tank waste cleanup mission at the Hanford Site in Washington state.

(002) 2x1.jpg)