Thinking outside the box, the nuclear sector puts a new spin on a pharmaceutical tool.

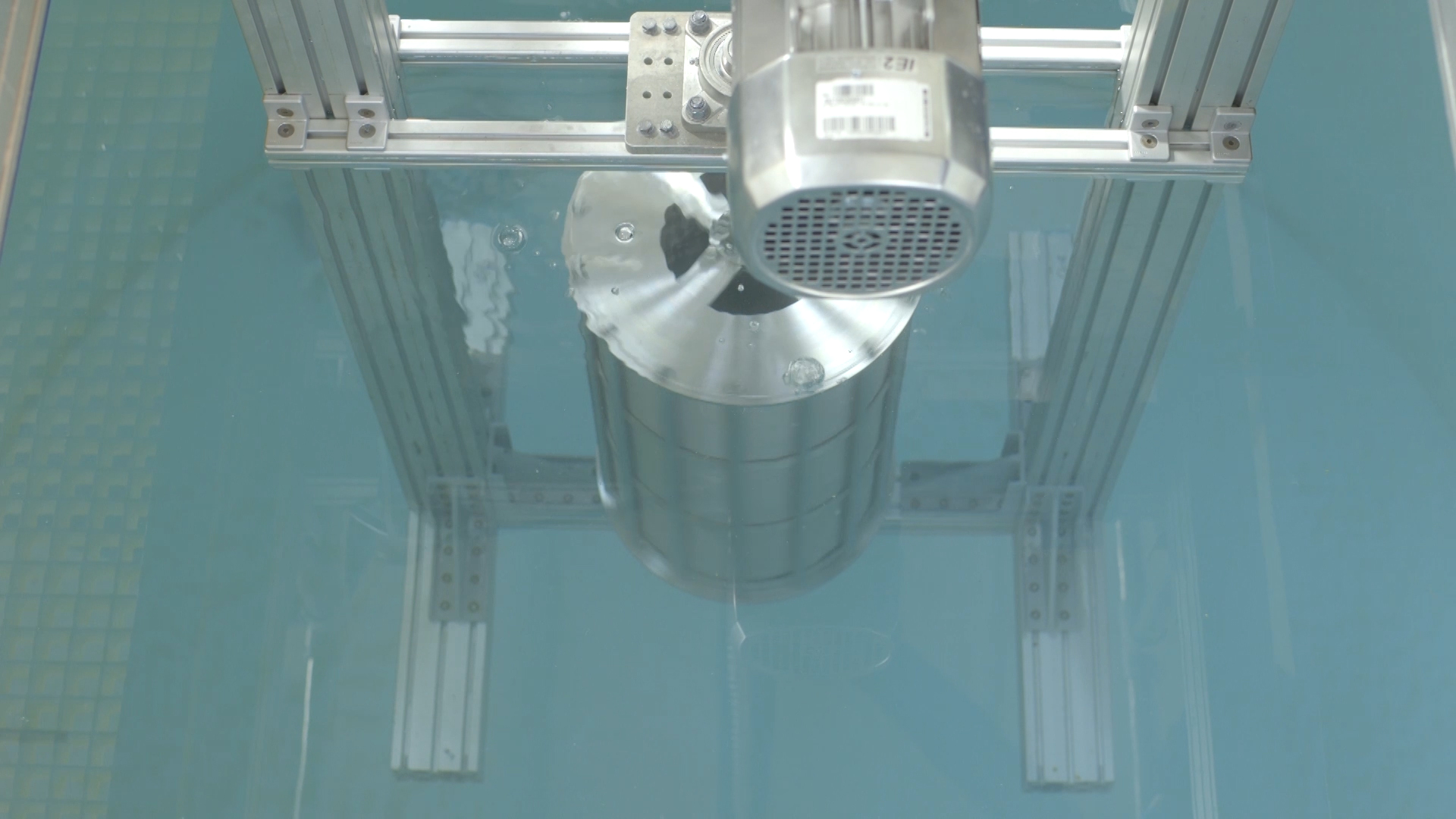

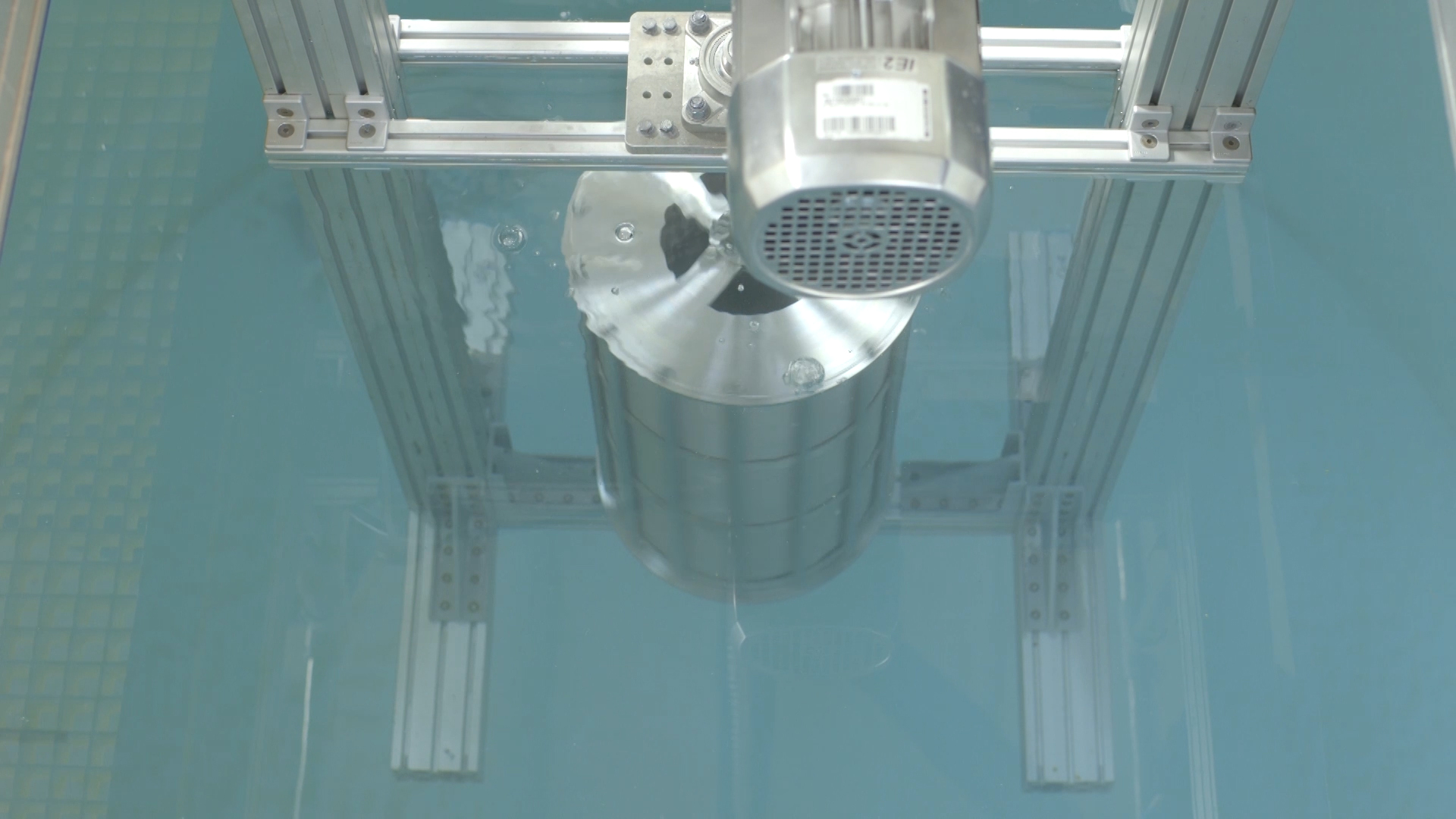

Large-scale testing is done on the Spinionic rotating bed reactor system.

We live in a world where we are continually driven to increase efficiency while decreasing costs—to do more with less. The nuclear industry is no different. Developing innovative techniques or adapting creative ideas found in other industries can support that pursuit to reduce cost and, in this case, volumes of waste, while providing program certainty. Such actions build confidence in our industry and allow nuclear power to continue to be part of the narrative of our clean-energy future.

The partial collapse of PUREX Tunnel 1 in 2017 prompted a review of Hanford’s maintenance of the site’s unused, contaminated buildings.

A report released to the public on February 20 by the Government Accountability Office concluded that maintenance inspections at several contaminated excess facilities at the Department of Energy’s Hanford Site, near Richland, Wash., have not been comprehensive and that there are areas of some facilities that personnel infrequently or never enter, either physically or by remote means, to conduct inspections. The GAO reviewed surveillance and maintenance (S&M) requirements and activities at 18 of Hanford’s approximately 800 excess facilities that require cleanup and found that improvements to the site’s S&M program are needed.

ASME Best Oral Presentation/Paper Waste Management 2019

March 10, 2020, 9:02AMRadwaste SolutionsThao Do, Jiju Joseph, Giles Whitaker, Barb Noye, Vasile Bostan, Don Jarron, and J. Clara Wren As nuclear power plants age and retire from service, many countries face significant challenges concerning the safe long-term storage and disposal of large volumes of low- and intermediate-level radioactive wastes (L&ILW). In Canada, Ontario Power Generation (OPG) is currently in the process of obtaining regulatory approval for a deep geological repository (L&ILW DGR) for such wastes from decommissioning and refurbishment of its heavy water reactors. OPG is exploring innovative methods and technologies to improve safety and reduce the processing, transportation, and disposal costs of these wastes. The volumes of metallic waste are of particular concern, because when metal corrodes it produces hydrogen that could lead to pressure buildup in the L&ILW DGR.

Bag-out operations can pose many issues to the TRU waste handling and disposal process. Among these are operator and facility safety, operational time, excess waste volume, and increased shipping costs to a waste repository.

Bag-out operations can pose many issues to the TRU waste handling and disposal process. Among these are operator and facility safety, operational time, excess waste volume, and increased shipping costs to a waste repository.