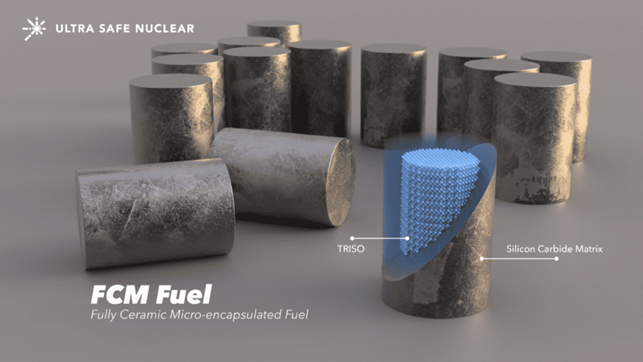

Fully ceramic microencapsulated fuel. Image: USNC

Canadian Nuclear Laboratories (CNL) announced last week that it has fabricated fully ceramic microencapsulated (FCM) fuel pellets, a proprietary reactor fuel designed by Ultra Safe Nuclear Corporation (USNC) for its Micro Modular Reactor (MMR). The FCM project, funded through the Canadian Nuclear Research Initiative (CNRI), represents the first time that tristructural isotropic (TRISO) fuel has been manufactured in Canada, according to CNL.

Miners depart Niger’s Akouta uranium mine for the last time after production ended for good. Photo: Cominak

The Akouta mine in Niger stopped production on March 31 after 43 years of service and 75,000 metric tons of uranium extracted. Akouta, the largest underground uranium mine in the world, was operated by Cominak, a subsidiary of Orano. The shutdown was decided by Cominak’s board of directors on October 23, 2019, in response to the depletion of the mine’s deposit.

The interior of the process building at the American Centrifuge Plant in Piketon, Ohio, where Centrus Energy plans to operate a HALEU demonstration cascade by June 2022. (Photo: Centrus Energy)

Advanced reactor cores are being designed for higher efficiencies and longer lifetimes, but to get there, they need high-assay low-enriched uranium (HALEU).

Enriched to between 5 and 19.75 percent fissile U-235, HALEU is packed with nuclear potential. It can be used as a feedstock for the demonstration of new fuel designs, from uranium alloys to ceramic pellets and liquid fuels. Those fuels can enable advanced reactor and microreactor demonstrations. Operating light-water reactors could potentially transition to HALEU uranium oxide fuels for extended operating cycles and improved plant economics.

Adequate uranium resources exist to support the long-term, sustainable use of nuclear energy for low-carbon electricity generation, as well as for other applications, including hydrogen production. That assessment is contained in the latest (28th) edition of

Adequate uranium resources exist to support the long-term, sustainable use of nuclear energy for low-carbon electricity generation, as well as for other applications, including hydrogen production. That assessment is contained in the latest (28th) edition of