A close-up of the ALTEMIS monitoring device.

(Photo: Brad Bohr/SRNL)

Researchers at Savannah River National Laboratory (SRNL), in concert with Lawrence Berkeley National Laboratory, Massachusetts Institute of Technology, Pacific Northwest National Laboratory, and Florida International University, are leading the Advanced Long-Term Environmental Monitoring Systems (ALTEMIS) project to move groundwater cleanup from a reactive process to a proactive process, while also reducing the cost of long-term monitoring and accelerating site closure.

The U.S. Army Corps of Engineers is safely cleaning up the former Maywood Chemical Works FUSRAP site in New Jersey.

USACE District Commander Mathew Luzzatto (right) is shown a map of the FUSRAP Maywood Superfund site in New Jersey in February 2023. (Photo: Nayelli Guerrero/USACE).

It is the 1940s in Maywood, N.J. A new residential community has sprouted up, and the homeowners want to beautify their front lawns, so they go to a nearby property to gather some fresh topsoil. Little did they know that they’re helping to plant the seeds for one of the largest and most high-profile environmental cleanup projects in the nation.

Vermont Yankee’s segmented reactor vessel head is lowered into a custom-built package for transportation and disposal. (Photo: Orano)

Currently, the Nuclear Regulatory Commission is overseeing 17 nuclear power plants that are undergoing active decommissioning. For 10 of those plants, the NRC licenses have been transferred, either through sale or temporary transfer, from the plant owner and operator to a third party, nonutility company for decommissioning. To be profitable, those companies are decommissioning the nuclear plants as expediently as they safely can, while still protecting workers and the environment, using proprietary techniques and processes.

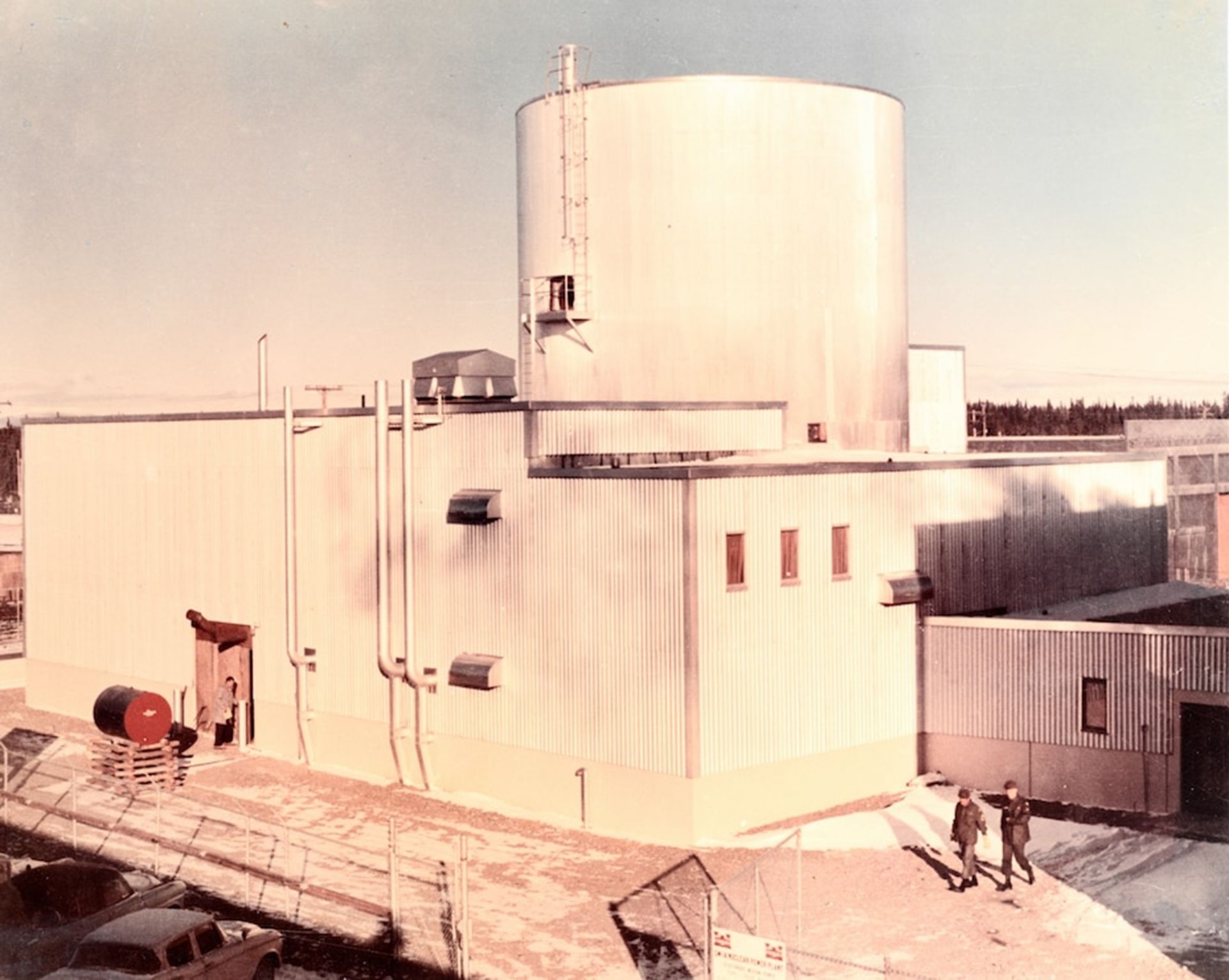

The SM-1A reactor facility at Fort Greely, Alaska. (Photo: USACE)

Baton Rouge, La.-based Aptim Federal Services announced that the U.S. Army Corps of Engineers, Baltimore District, has awarded the company a six-year, $95.5 million contract to decommission, dismantle, and dispose of the SM-1A nuclear power reactor at Fort Greely, Alaska.

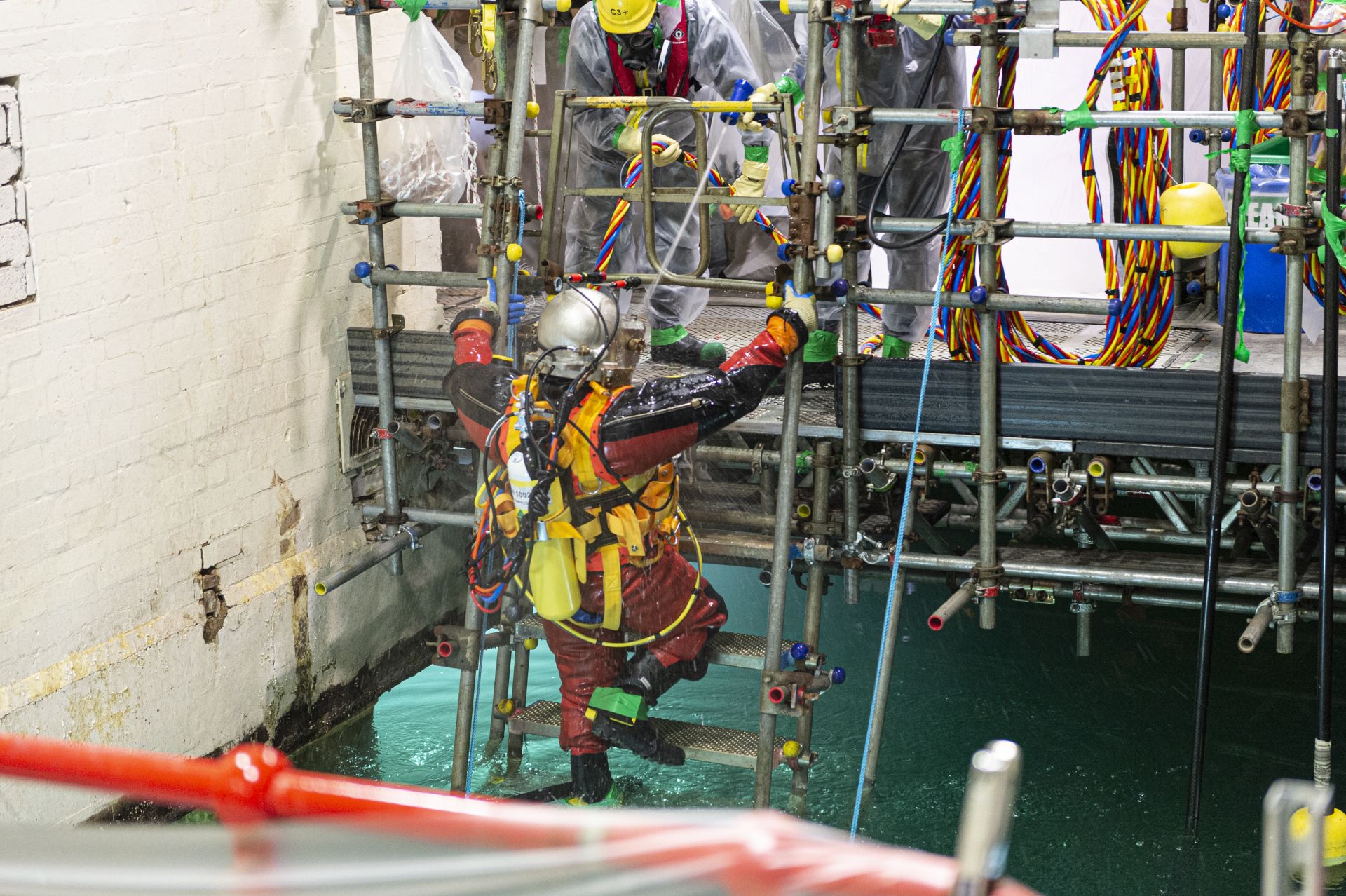

Josh Everett, a diver with UCC UK Ltd., enters bay No. 11 of Sellafield’s Pile Fuel Storage Pond in December 2022, the first time in over 60 years a diver has entered the legacy pond, used to store a variety of spent nuclear fuel types and wastes. During this commissioning nuclear dive, Everett’s underwater tasks included emergency diver extraction trial confirmation, radiation monitoring system verification, and radiation contact meter commissioning. (Photos courtesy of Sellafield Ltd.)

The last time a human entered the Pile Fuel Storage Pond at the Sellafield nuclear site in Cumbria, England, was in 1958, when records show a maintenance operator and health physics monitor carried out a dive into the newly constructed pond to repair a broken winch. At least that was true until December 2022, when Josh Everett, a diver from the U.K. specialist nuclear diving team Underwater Construction Corporation (UCC) UK Ltd., became the first person in more than 60 years to work in one of the most unique workplaces in the world.

The DOE-EM–Sandia team and Sellafield representatives pose with Spot Robot at the Sellafield Engineering and Maintenance Centre of Excellence. (Photo: DOE)

Robotics experts from Sandia National Laboratories and representatives from the Department of Energy Office of Environmental Management’s Technology Development Office recently visited the Sellafield nuclear site in England to discuss how robotics, artificial intelligence, and other emerging tools can be developed and used in nuclear cleanup operations.

The Alpha-2 building at Y-12 in Oak Ridge is a former uranium enrichment facility that dates to the Manhattan Project era. (Photo: DOE)

The Department of Energy’s Office of Environmental Management said that crews have completed major deactivation efforts at the Alpha-2 building at the Y-12 National Security Complex in Oak Ridge, Tenn. The former uranium enrichment facility is scheduled for demolition next year.

Work crews use light construction equipment to remove the final pieces of asphalt from one of the pads at the TSA-RE at INL. (Photo: DOE)

The Idaho National Laboratory is moving closer toward closing its largest building—which, at more than 316,000 square feet, could comfortably house a modern U.S. aircraft carrier, according to the Department of Energy.

Portsmouth’s X-326 Process Building undergoes demolition in 2022. (Photo: DOE)

The Department of Energy’s Office of Environmental Management awarded a 10-year contract worth up to $5.87 billion to Southern Ohio Cleanup Company (SOCCo) of Aiken, S.C., for the decontamination and decommissioning of the DOE’s Portsmouth site in southern Ohio. SOCCo is a newly formed limited liability company comprising Amentum Environment and Energy, Fluor Federal Services, and Cavendish Nuclear (USA) Inc.

The Holtec HI-LIFT at Indian Point-3. (Image: Holtec)

Holtec International has said its patented HI-LIFT crane technology, being installed at the Indian Point-3 nuclear power plant, will speed the defueling of the spent nuclear fuel pool and avoid millions in excess decommissioning costs.

This image of the PUREX plant was used to demonstrate how a 3D laser scanning tool could capture the layout of facilities being prepared for demolition. (Image: DOE)

A team of designers from Central Plateau Cleanup Company (CPCCo), a contractor of the DOE-EM Richland Operations Office, is using 3D laser scanning technology to gather data to help workers prepare some of the facilities at the Hanford Site for demolition.

For the first time in 26 years, work crews performed sampling of gaseous byproducts at the MSRE. (Photo: DOE)

The Vallecitos Nuclear Center in northern California. (Photo: Wikimedia Commons)

GE Hitachi Nuclear Energy announced May 9 that it intends to transfer ownership of the 1,600-acre GEH Vallecitos Nuclear Center to NorthStar Group Services for nuclear decontamination, decommissioning, and environmental site restoration.

Crews recently replaced a motor in a crane at the SRS H Canyon for the first time in the facility’s 70-year history. (Photo: DOE)

Work crews at the Department of Energy’s Savannah River Site in South Carolina recently replaced a motor on a crane in the 70-year-old H Canyon Chemical Separations Facility. H Canyon is the only production-scale, radiologically shielded chemical separations plant in operation in the United States.

The Nuclear Decommissioning Authority, the governmental organization responsible for the cleanup and decommissioning of the United Kingdom’s 17 nuclear sites, has released its business plan for the fiscal years running from April 1, 2023, through March 31, 2026. The plan provides a summary of the activities and progress the NDA expects to make at its nuclear sites over the next three years.

The Nuclear Decommissioning Authority, the governmental organization responsible for the cleanup and decommissioning of the United Kingdom’s 17 nuclear sites, has released its business plan for the fiscal years running from April 1, 2023, through March 31, 2026. The plan provides a summary of the activities and progress the NDA expects to make at its nuclear sites over the next three years.