The Hanford Field Office leadership team gathers around a new sign at the Stevens Center Complex in Richland, Wash., on October 1. (Photo: DOE)

Beginning last week, the two Department of Energy offices responsible for the environmental cleanup of the department’s Hanford Site have been combined under a new name: the Hanford Field Office. Previously, management of the 586-square-mile site near Richland, Wash., was split between the Richland Operations Office and the DOE Office of River Protection (ORP).

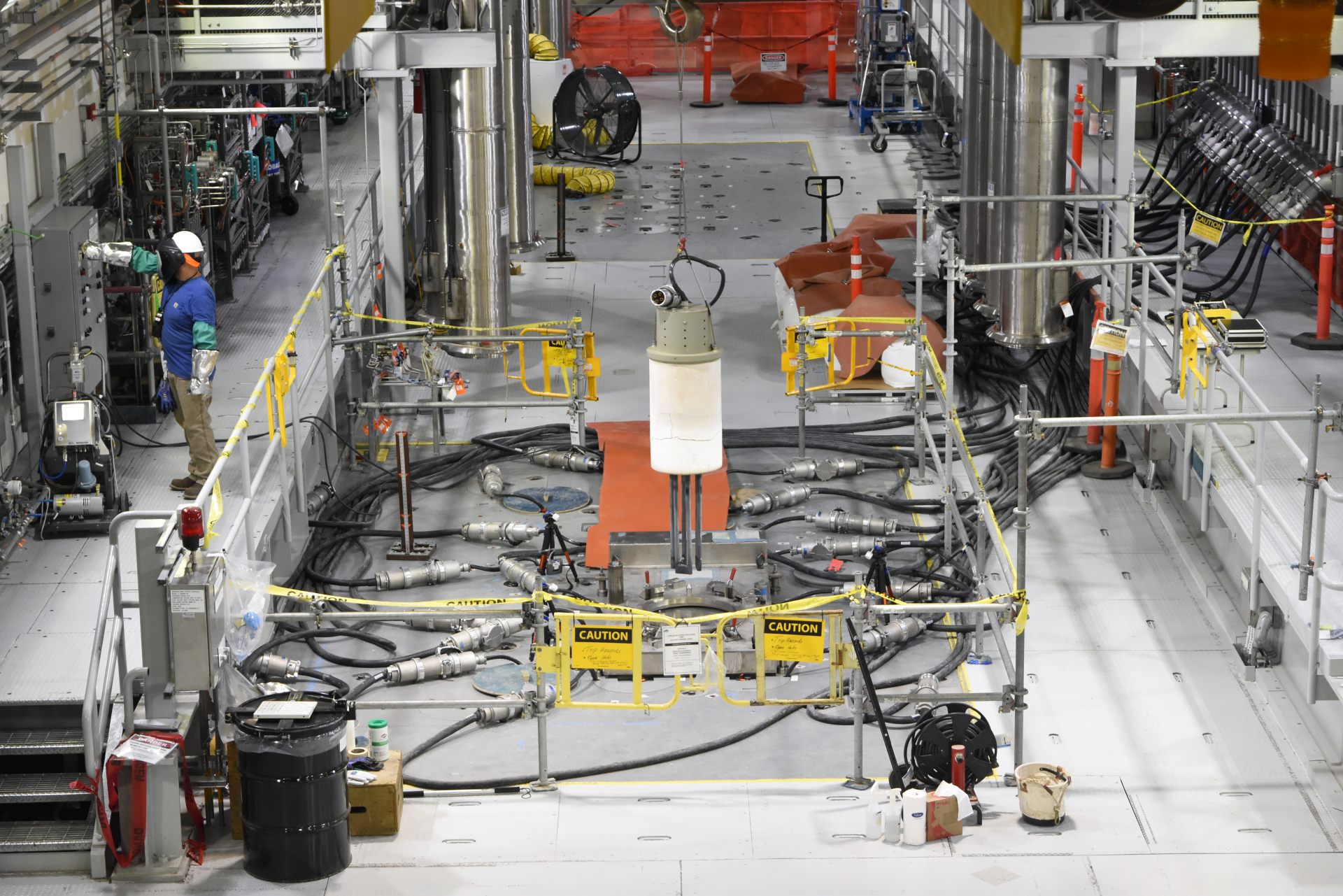

Hanford’s HLW Facility under construction in early 2024. (Photo: Bechtel National)

The Government Accountability Office has recommended that the Department of Energy put a hold on construction of its High-Level Waste Facility at the Hanford Site near Richland, Wash. The GAO said design and construction of the facility, part of Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, should be paused until several actions are taken, including considering other alternatives for managing the site’s high-level radioactive liquid waste.

Hanford workers recently transferred three containers of nonradioactive test glass from the site’s WTP to the nearby Integrated Disposal Facility. (Photos: DOE)

According to the Department of Energy’s Office of Environmental Management, two contractors at its Hanford Site in Washington state have finished a first-time relay of test glass as the site prepares to vitrify—or immobilize in glass—millions of gallons of radioactive and chemical waste from its large underground tanks.

Video: Watch an “instant replay” of the test glass relay here.

Lourdes Legaspi, engineering automation supervisor (center) and her team are designing pipe and equipment components for the Hanford Site’s partially completed HLW Facility. A collaboration between the DOE and Bechtel National set a foundation for requirements engineers will follow in continuing the design of the facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management announced that its Office of River Protection (ORP) recently created a plan with contractor Bechtel National for completing the High-Level Waste Facility at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

Vit Plant crews begin adding frit into Hanford’s second melter. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management recently announced that crews at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, recently brought the second of two 300-ton melters up to the operating temperature of 2,100°F.

One of 18 startup heaters is installed in Hanford’s second melter, which will be used to vitrify liquid waste. (Photo: DOE)

The Department of Energy’s Office of Environmental Management announced that crews at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, recently installed 18 temporary startup heaters in the second of two melters in the plant’s Low-Activity Waste Facility.

Crewmembers stand in front of the first stainless-steel container filled with molten test glass at Hanford’s Vit Plant. (Photo: Bechtel National)

Bechtel and the Department of Energy’s Office of Environmental Management announced on December 4 that the first set of test glass was successfully poured into a stainless-steel storage container designed to hold vitrified waste at Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

Workers monitor the pouring of melter glass from a control room in Hanford’s LAW Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management said crews at its Hanford Site in Washington state have started pouring the first molten glass from a waste vitrification melter into a stainless steel container at the site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

A startup heater is removed from a melter in the Vit Plant’s Low-Activity Waste Facility. (Photo: DOE)

Workers at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, have begun removing the first three of 18 temporary startup heaters, the Department of Energy announced on September 12. The startup heaters were used to raise the first of two 300-ton glass melters in the plant’s Low-Activity Waste Facility to its operating temperature of 2,100°F.

A 300-pound bag of frit is in position to be poured into the melter at Hanford’s LAW Facility. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management announced that the first batches of glass-forming beads, called frit, were poured last week into a melter at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP), also known as the Vit Plant. The melter, which has been heated to 2,100ºF, will be used to immobilize Hanford’s radioactive and chemical tank waste, turning it into a stable glass form through vitrification.

Hanford’s Waste Treatment and Immobilization Plant. (Photo: DOE)

The Department of Energy is asking for feedback on a new report analyzing potential options for preparing high-level radioactive waste for vitrification at the department’s Hanford Site near Richland, Wash. Vitrification is the process of treating radioactive waste by immobilizing it in glass.

The report, Waste Treatment and Immobilization Plant High-Level Waste Treatment: Analysis of Alternatives, was commissioned in response to a 2018 determination by the U.S. Army Corps of Engineers that it was unlikely the DOE would meet its mandated deadlines for treating Hanford’s tank waste.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

Electrician Ralph Bisla conducts tests of the finishing line inside Hanford’s WTP Low-Activity Waste Facility. (Photo: DOE)

Having completed all startup testing of components and systems, the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site near Richland, Wash., has moved to the commissioning phase, the Department of Energy’s Office of Environmental Management (EM) announced last week. During the commissioning phase, the final steps will be taken to prepare for the vitrification of radioactive and chemical waste as part of Hanford’s Direct-Feed Low-Activity Waste (DFLAW) program.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management (EM) has issued a final request for proposal (RFP) for the Hanford Integrated Tank Disposition Contract, a 10-year, $45 billion deal to oversee waste tank operations at the DOE’s Hanford Site near Richland, Wash. Proposals are due by December 20.

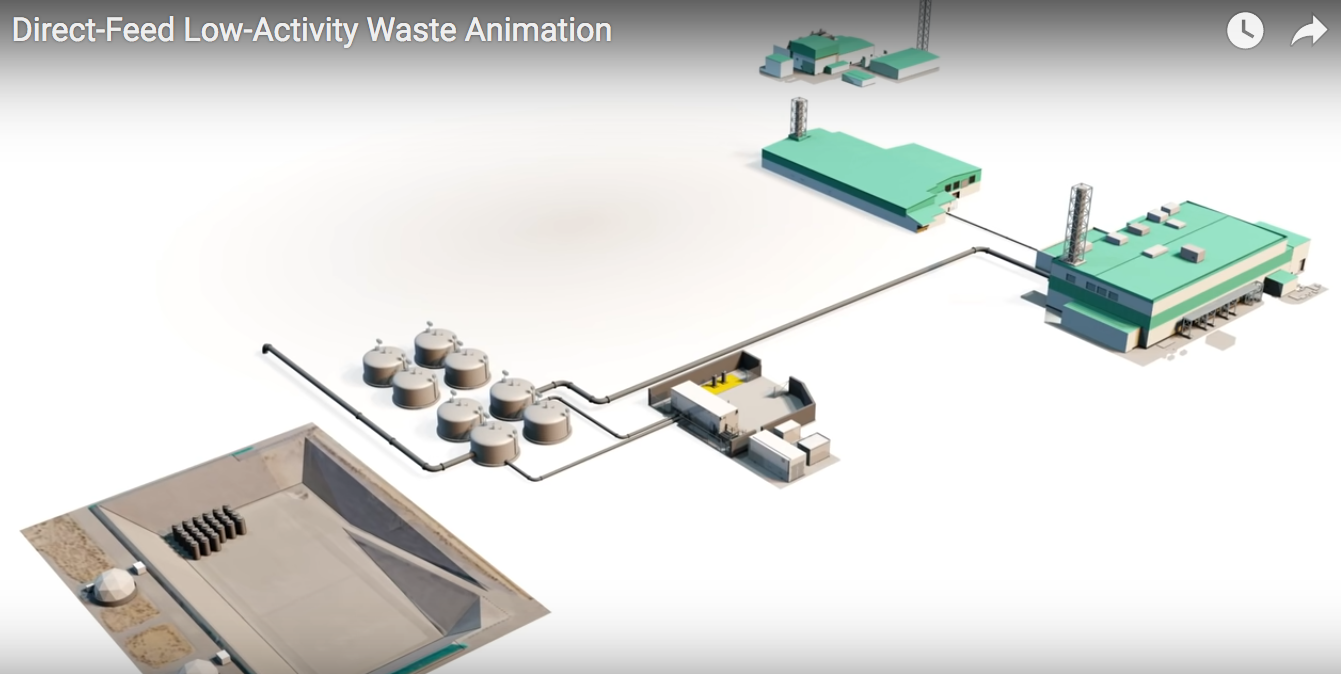

A screen shot from Hanford’s DFLAW animation. (Image: DOE)

The Department of Energy’s Office of Environmental Management (EM) has released an animated video of the Direct-Feed Low-Activity Waste (DFLAW) Program at the Hanford Site near Richland, Wash. The video shows the integrated procedure for treating Hanford’s radioactive tank waste, a process EM says is a key component of its strategic cleanup vision.

View the animation here.

Hanford workers fit sections of double-walled pipe in place, connecting the site’s tank farms to the Waste Treatment and Immobilization Plant. (Screen shot: WRPS/YouTube)

The Department of Energy is celebrating a major milestone in its tank waste mission at the Hanford Site near Richland, Wash. DOE tank operations contractor Washington River Protection Solutions has finished construction of the pipeline that will carry treated waste from an underground tank to the Waste Treatment and Immobilization Plant (WTP) for vitrification.