Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

BWX Technologies announced that the Department of Energy has approved Hanford Tank Waste Operations & Closure (H2C) to begin work under a contract valued at up to $45 billion to clean up tank waste at the Hanford Site near Richland, Wash. H2C is a limited liability company made up of BWXT Technical Services Group, Amentum Environment and Energy, and Fluor Federal Services.

Stephanie Doll of WRPS poses next to the metal patch applied during the demonstration. (Photo: DOE)

The Department of Energy’s Office of Environmental Management and its contractor Washington River Protection Solutions (WRPS) recently demonstrated the use of cold spray technology as a means of refurbishing double-shell waste tanks at the Hanford Site in Washington state. The tanks store liquid radioactive and chemical waste that was created during Hanford’s plutonium production era.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management once again awarded a 10-year, $45 billion contract to Hanford Tank Waste Operations and Closure (H2C) of Lynchburg, Va., for the cleanup of tank waste at the Hanford Site.

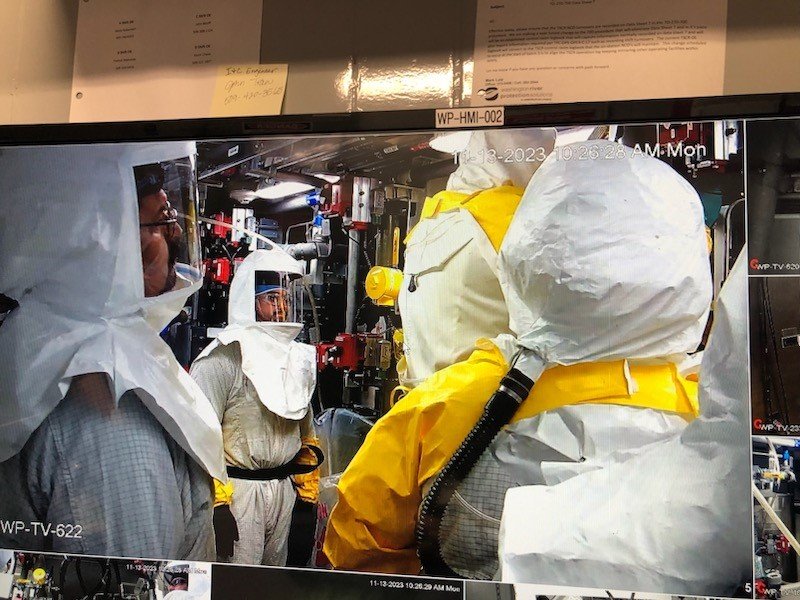

A monitor in the control room of the Hanford Site’s TSCR system shows workers performing maintenance inside the TSCR facility. (Photo: DOE)

The Department of Energy Office of Environmental Management’s Office of River Protection and contractor Washington River Protection Solutions have completed the first waste processing campaign through the Tank-Side Cesium Removal (TSCR) system at the Hanford Site.

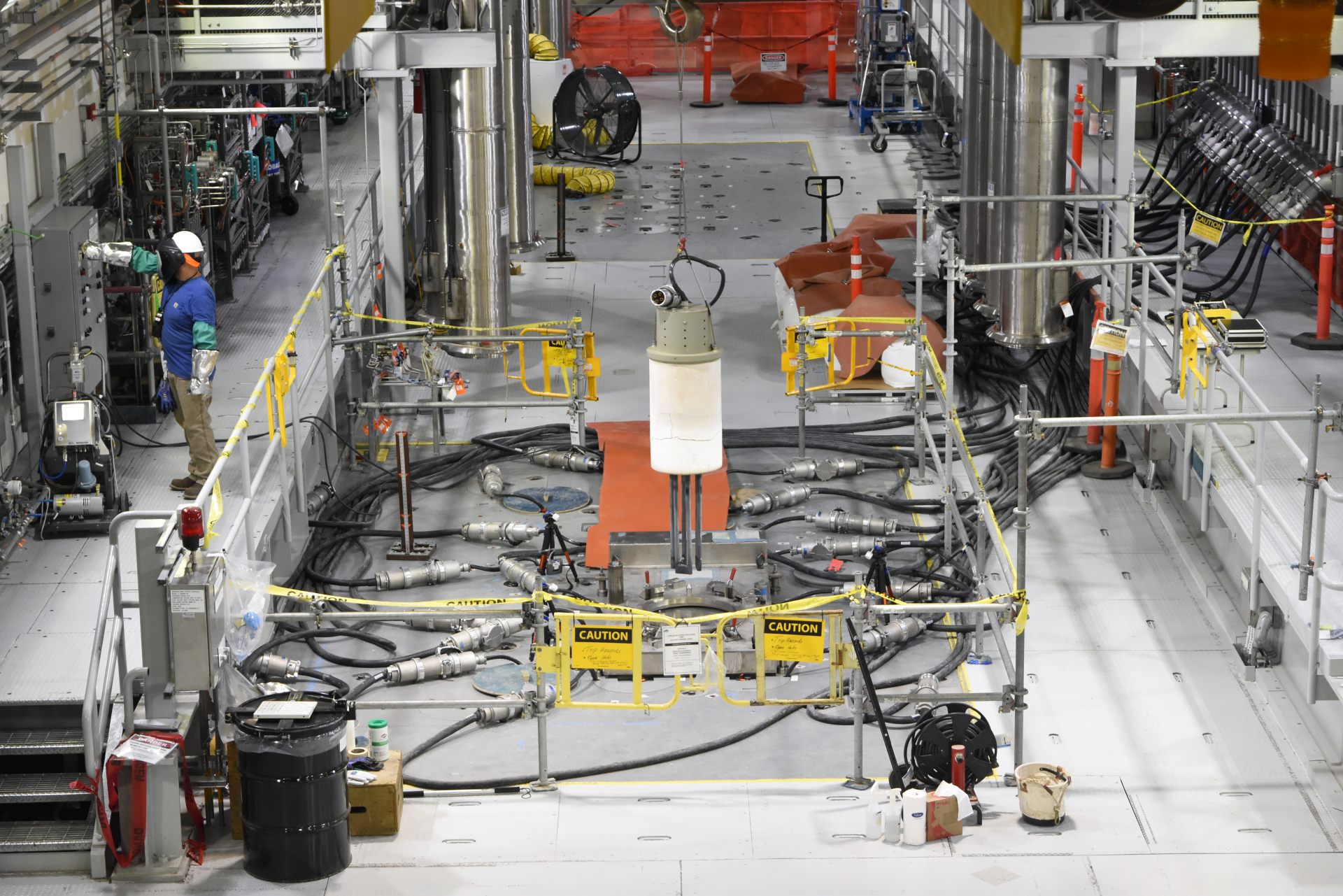

A startup heater is removed from a melter in the Vit Plant’s Low-Activity Waste Facility. (Photo: DOE)

Workers at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, have begun removing the first three of 18 temporary startup heaters, the Department of Energy announced on September 12. The startup heaters were used to raise the first of two 300-ton glass melters in the plant’s Low-Activity Waste Facility to its operating temperature of 2,100°F.

Photos taken inside Hanford’s Tank AX-101 before workers started removing radioactive and chemical waste from it in January. As of April 18, crews have removed 35 percent of the tank waste. (Photos: DOE)

The Department of Energy’s Office of Environmental Management (EM) said in an April 18 release that workers have so far removed almost 150,000 gallons, or about 35 percent, of the radioactive and chemical waste from Tank AX-101 at the department’s Hanford Site near Richland, Wash. Retrieval from this tank began in January.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management awarded a 10-year contract worth up to $45 billion to Hanford Tank Waste Operations and Closure (H2C) of Lynchburg, Va., to oversee the management of liquid radioactive tank waste at the DOE’s Hanford Site in southeastern Washington state.

Workers install one of 18 startup heaters into Melter 1 of Hanford’s Low-Activity Waste Facility. (Photo: Bechtel National)

Heating of the first waste vitrification melter at the Department of Energy’s Hanford Site was paused after operators identified an “abnormal condition with the startup heater power supplies,” the DOE’s Office of River Protection (ORP) said. Heat-up of the 300-ton melter, which will be used to vitrify Hanford’s low-level radioactive tank waste, was initiated on October 8.

Hanford workers will soon begin retrieving about 373,000 gallons of waste from Tank AX-101, shown here in an image from an inspection video shot. (Photo: DOE)

Washington River Protection Solutions (WRPS) is preparing to retrieve waste from Tank AX-101 at the Department of Energy’s Hanford Site near Richland, Wash. WRPS is the tank operations contractor at Hanford.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.

Hanford workers fit sections of double-walled pipe in place, connecting the site’s tank farms to the Waste Treatment and Immobilization Plant. (Screen shot: WRPS/YouTube)

The Department of Energy is celebrating a major milestone in its tank waste mission at the Hanford Site near Richland, Wash. DOE tank operations contractor Washington River Protection Solutions has finished construction of the pipeline that will carry treated waste from an underground tank to the Waste Treatment and Immobilization Plant (WTP) for vitrification.

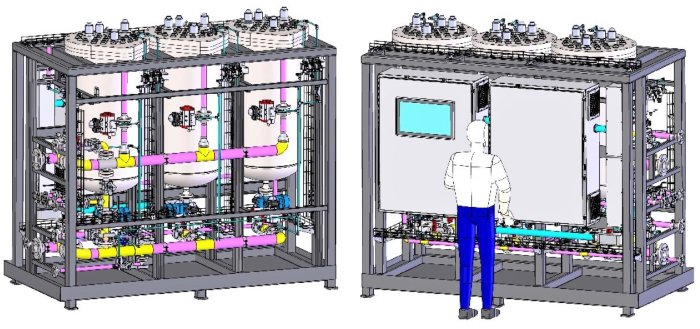

A front-and-back illustration of the new Hanford ETF filter system, which is intended to eliminate the need to shut down operations every 12 hours to replace filters during wastewater processing. Image: DOE

A new wastewater filter system being installed at Hanford’s Effluent Treatment Facility (ETF) is expected to increase waste processing throughput, improve efficiency, and save money as the site in southeastern Washington gears up to treat tank waste, the Department of Energy announced.