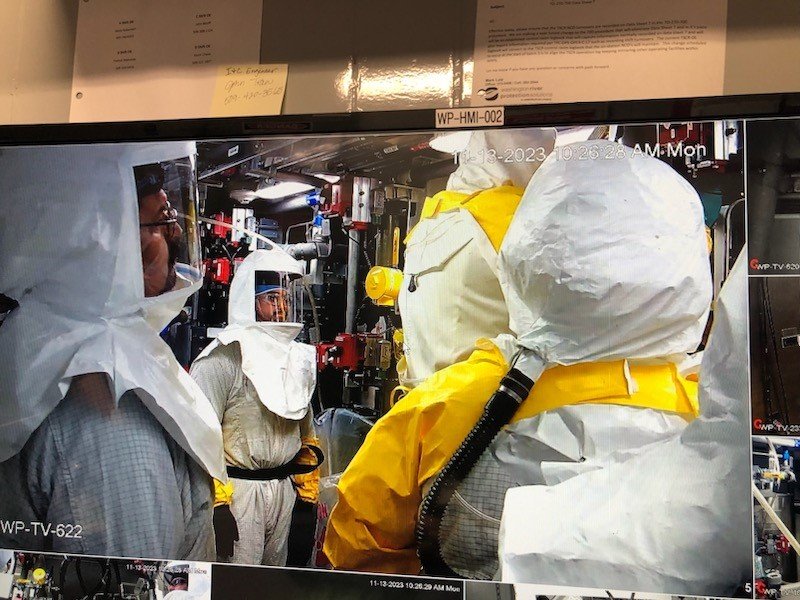

A monitor in the control room of the Hanford Site’s TSCR system shows workers performing maintenance inside the TSCR facility. (Photo: DOE)

The Department of Energy Office of Environmental Management’s Office of River Protection and contractor Washington River Protection Solutions have completed the first waste processing campaign through the Tank-Side Cesium Removal (TSCR) system at the Hanford Site.

Training instructor Chris Oliveros poses inside a new radiological control training classroom at Hanford’s WTP. (Photo: DOE)

The training team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently added an extra level of realism to employee trainings by upgrading classrooms and adding new props, according to the Department of Energy.

The Hanford Site’s ETF has been expanded. (Photo: DOE)

The Hanford Site’s Effluent Treatment Facility (ETF) has been expanded and will be able to handle almost 7 million more gallons of wastewater per year once the site’s Waste Treatment and Immobilization Plant (WTP) begins treating waste from large underground tanks.

Concrete blocks are loaded onto a metal base and transporter during tests on a gantry crane system that will lift replacement melters for Hanford’s WTP. (Photo: DOE)

The Department of Energy has announced that tank operations contractor Washington River Protection Solutions (WRPS) and subcontractor Atkins are making progress at the Hanford Site in Washington state in their preparations to provide replacement melters to treat radioactive and chemical tank waste for the site’s Direct-Feed Low-Activity Waste program.

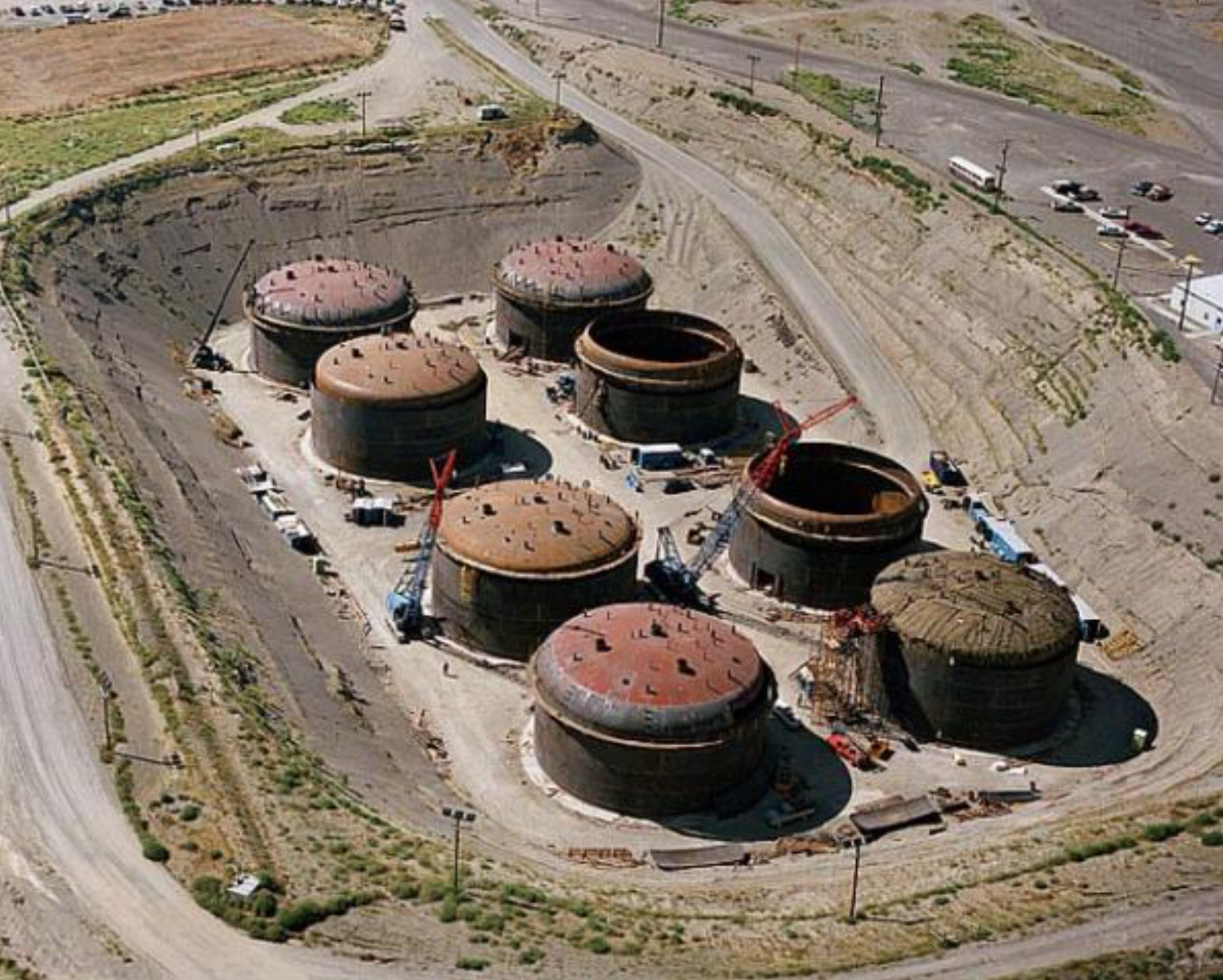

Retention basins at the Liquid Effluent Retention Facility on the Hanford Site, as seen in September 2021, at top, and recently with the nearly completed Basin 41 on the far left. (Photo: DOE)

Work is nearing completion on a fourth basin needed to ensure adequate storage for wastewater during tank waste treatment on the Department of Energy’s Hanford Site, in Washington state.

According to the DOE, its operations contractor Washington River Protection Solutions (WRPS) has made significant progress on Basin 41 at the Liquid Effluent Retention Facility (LERF) since concrete was first poured for the perimeter one year ago.

Video: Watch this time-lapse video of the LERF Basin 41 construction.

A worker watches test bubblers in operation at the Hanford Site. (Photo: DOE)

During the Hanford Site's Direct-Feed Low-Activity Waste Program treatment operations, the Waste Treatment and Immobilization Plant, background, will feed liquid waste to the Liquid Effluent Retention Facility, foreground, through a primary transfer line pictured here. (Photo: DOE)

Work crews at the Department of Energy's Hanford Site recently completed the first transfer of test water from the Waste Treatment and Immobilization Plant's Effluent Management Facility to the nearby Liquid Effluent Retention Facility (LERF). The transfer of 6,000 gallons was the first simulation of the process that will be used to treat secondary liquid waste from the plant’s Low-Activity Waste Facility during operations to treat tank waste.

“This is a tremendous accomplishment that culminates years of work by our team and alumni toward being ready for hot commissioning,” said Valerie McCain, project director and senior vice president for Bechtel National, Inc. “It’s an important step for the entire Hanford team and our collective mission of protecting the Columbia River and its shoreline communities.”

Bechtel National is a contractor of the DOE's Office of Environmental Management's Office of River Protection.

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.