NEA director general William Magwood (left) and EPRI senior vice president Neil Wilmshurst finalize EPRI support for the joint WISARD project. (Photo: NEA)

The Nuclear Energy Agency has announced a new collaboration with the Electric Power Research Institute on an upcoming project that will focus on waste management strategies for small modular reactors and advanced nuclear energy systems.

Representatives from OPG, Laurentis Energy Partners, and EnergySolutions Canada, as well as the mayor of Kincardine, Kenneth Craig, cut the ceremonial ribbon to officially open WCSR facility. (Photo: OPG)

Ontario Power Generation (OPG) subsidiary Laurentis Energy Partners has opened, in partnership with EnergySolutions Canada, a new 42,000-square-foot facility in Kincardine, Ontario, that will minimize waste associated with nuclear energy generation in the Canadian province, the company announced this week.

Crews with Hanford contractor Central Plateau Cleanup Company break up concrete and remove contaminated soil near the former K Area reactors on the Hanford Site earlier this year. (Photo: DOE)

The Department of Energy is seeking the public’s input on the Hanford Site’s 5-year plan, which outlines planned cleanup work either to be completed or initiated at the former plutonium production site near Richland, Wash. The DOE updates Hanford’s 5-year plan annually to reflect current progress and ongoing integrated planning for future work at the site.

Ray Tran, an engineer for Savannah River tank farms, helps complete a timeline of SRS historical events as part of SRMC’s vision casting training initiative. (Photo: DOE)

More than 3,000 employees with Department of Energy contractor Savannah River Mission Completion (SRMC) participated in a vision casting initiative, learning more about the past, present, and future of the Savannah River Site’s liquid waste mission.

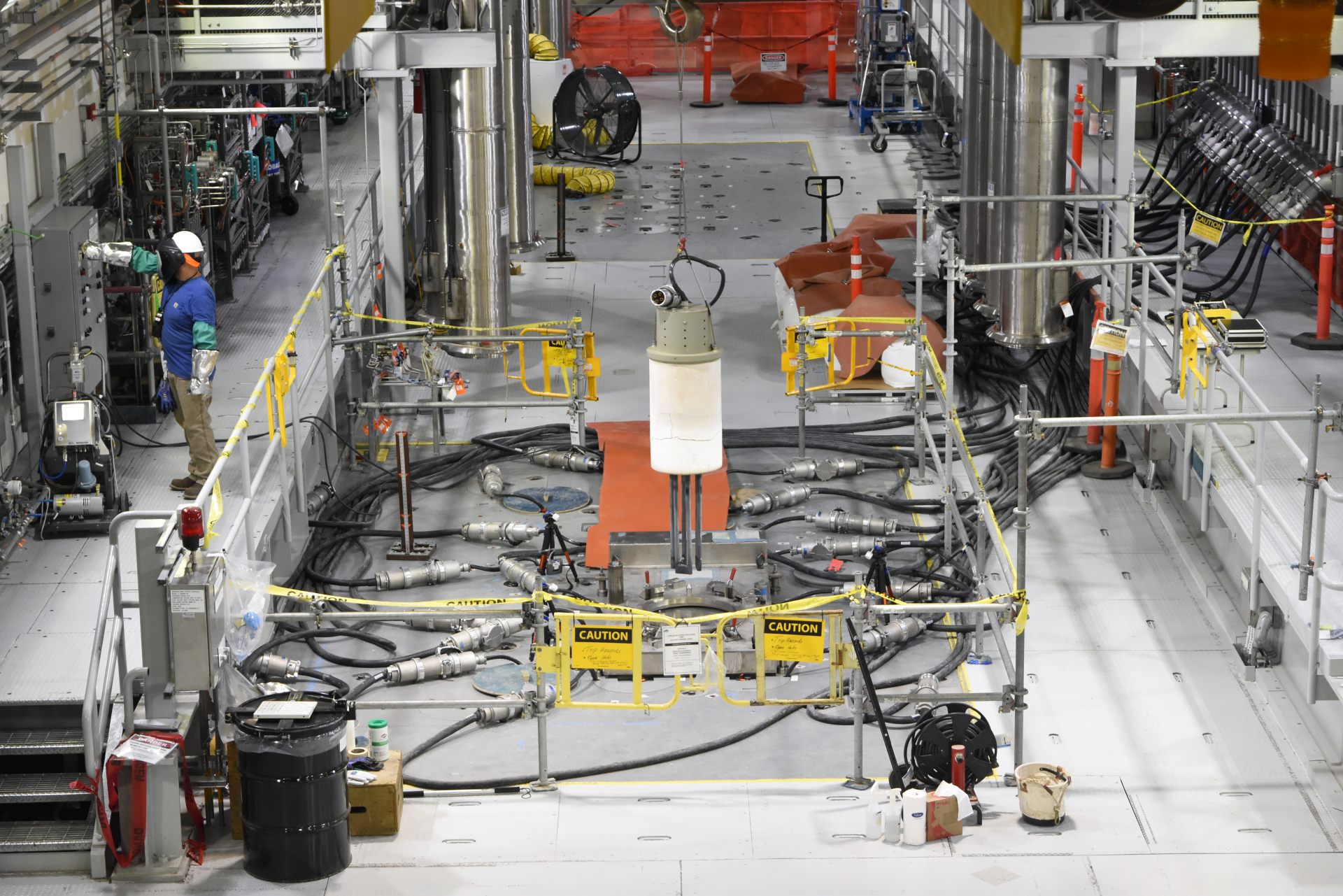

A startup heater is removed from a melter in the Vit Plant’s Low-Activity Waste Facility. (Photo: DOE)

Workers at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, have begun removing the first three of 18 temporary startup heaters, the Department of Energy announced on September 12. The startup heaters were used to raise the first of two 300-ton glass melters in the plant’s Low-Activity Waste Facility to its operating temperature of 2,100°F.

The SONGS independent spent fuel storage installation. (Photo: SCE)

Spent Fuel Solutions, which advocates for a permanent disposal solution for the nation’s spent nuclear fuel, will be holding an informational webinar on Friday, September 15, from 11:00 a.m. to noon (PDT).

Taking part in the Environmental Management Disposal Facility groundbreaking, from left, were Steve Arnette of Jacobs; Mark Whitney of Amentum,; Wade Creswell, a Roane Co., Tenn., executive; Brent Booker of the Laborers’ International Union of North America; Kevin Adkisson of North America’s Building Trades Unions; Jeaneanne Gettle of the EPA; Lt. Gov. Randy McNally; David Salyers of TDEC; Ken Rueter of UCOR; Jay Mullis of OREM; U.S. Rep. Chuck Fleischmann; and DOE-EM’s William “Ike” White. (Photo: DOE)

National, state, and local leaders joined the Department of Energy’s Oak Ridge Office of Environmental Management (OREM) and its lead cleanup contractor, United Cleanup Oak Ridge (UCOR), earlier this month to celebrate the groundbreaking for a new on-site disposal facility at the Oak Ridge Reservation in Tennessee.

Watch a video highlighting the Environmental Management Disposal Facility groundbreaking ceremony here.

The Pile Fuel Cladding Silo on the Sellafield site in West Cumbria, England. (Photo: Sellafield Ltd.)

After decades of planning and weeks of preparation and checks, the first batch of legacy waste has been retrieved from the Pile Fuel Cladding Silo at the Sellafield nuclear site in West Cumbria, England. According to Sellafield Ltd., the site license company, a state-of-the-art robotic arm was used to reach into the silo and, for the first time, remove and repackage the waste for longer-term storage.

These retrievals mark a significant achievement in progress toward the cleanup and decommissioning of one of the most hazardous buildings on the site, according to Sellafield Ltd., which made the announcement on August 16.

Watch a video about the Pile Fuel Cladding Silo and Sellafield’s waste retrieval operations here.

Finalized report incorporates feedback on revisiting EPA regulations

Downers Grove, Illinois – The American Nuclear Society (ANS) published a finalized report on recommendations for updating public health and safety standards for the permanent disposal of commercial used nuclear fuel and high-level radioactive waste at future geological repository projects in the United States.

A schematic illustration of a deep borehole repository assuming disposal into a bedrock. (Image: Sandia National Laboratories via IAEA)

The International Atomic Energy Agency is launching a new Coordinated Research Project (CRP) to increase international knowledge and drive progress toward testing deep borehole disposal for intermediate- and high-level radioactive waste.

A new IAEA peer review service demonstrates the proper management of disused sealed radioactive sources. (Photos: IAEA [left] and TINT [right])

The International Atomic Energy Agency has carried out the first mission of its Disused Sealed Radioactive Sources Technical Centre peer review service, or DSRS TeC, at the Thailand Institute of Nuclear Technology (TINT) in Bangkok. Held July 18–21, the inaugural mission was supported by funds from the United States.

A 300-pound bag of frit is in position to be poured into the melter at Hanford’s LAW Facility. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management announced that the first batches of glass-forming beads, called frit, were poured last week into a melter at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP), also known as the Vit Plant. The melter, which has been heated to 2,100ºF, will be used to immobilize Hanford’s radioactive and chemical tank waste, turning it into a stable glass form through vitrification.