Holtec to step up its production of spent fuel casks

A Holtec HI-STAR 150 cask being placed into storage at Cofrentes in Spain on June 23. (Photo: Holtec).

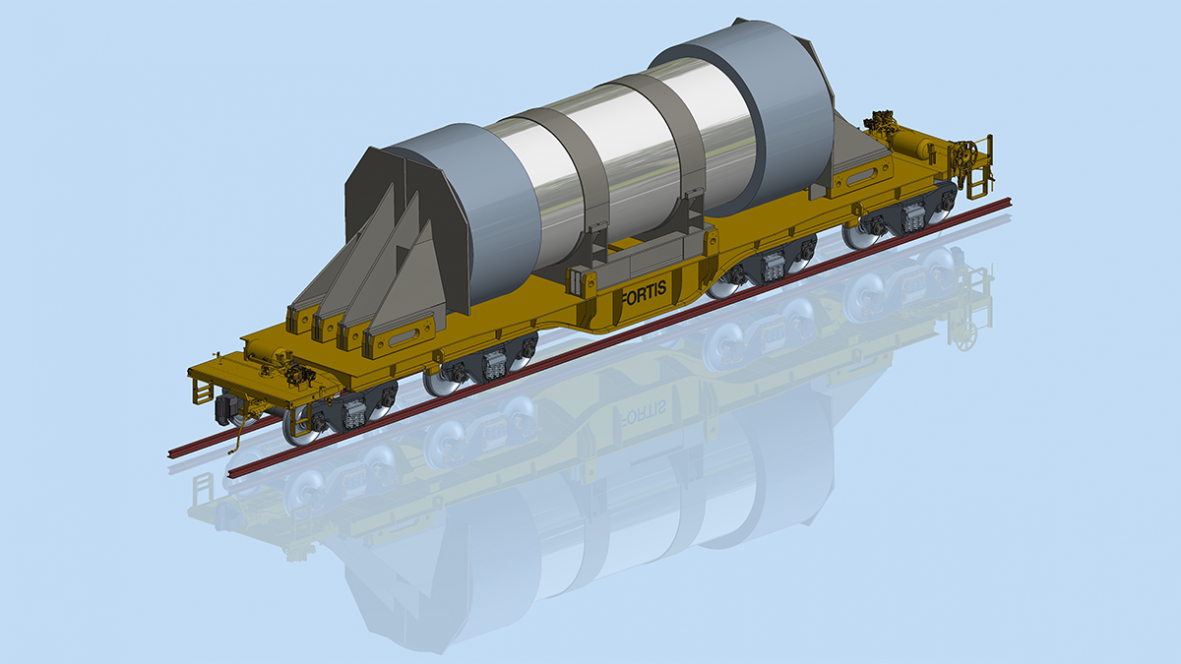

Holtec International is increasing the production of its HI-STAR casks for storing and transporting spent nuclear fuel following recent regulatory approvals and new orders in Europe. Earlier this month the company was awarded a contract by Spain’s waste management organization Enresa for 10 HI-STAR 150 casks, and Holtec is currently in the advanced stages of production of two HI-STAR 180D casks destined for the Doel nuclear power plant in Belgium, with additional orders pending.

The casks are being produced at Holtec’s manufacturing facilities in New Jersey, Pennsylvania, and Ohio.

Spain: Enresa initially awarded Holtec a contract in 2017 for the design, engineering, licensing, and manufacturing of five HI-STAR 150 casks for the Cofrentes nuclear power plant near Valencia. The Spanish Nuclear Safety Council signed off on the HI-STAR 150 design for storage in April of this year, and on May 23, Spain’s Ministry of Ecological Transition and the Demographic Challenge granted a license for the cask, which is designed to store up to 52 boiling water reactor spent fuel assemblies, including damaged fuel assemblies.