DOE gets go-ahead to build spent fuel/high-level waste railcars

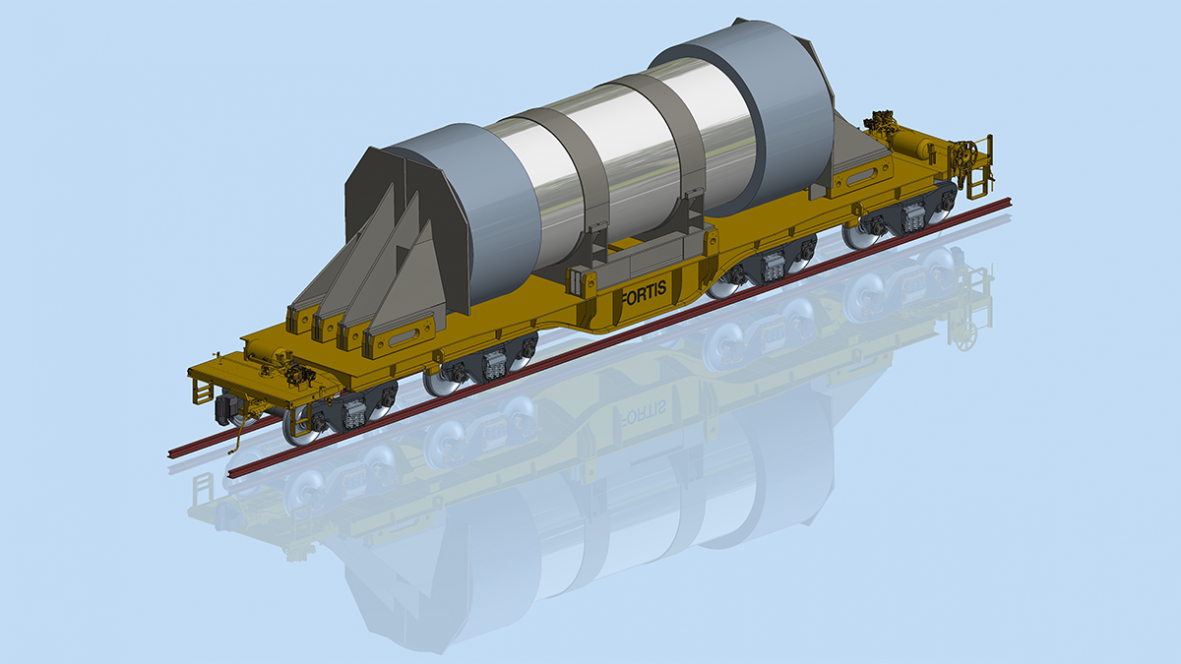

Graphical rendering of Fortis railcar design with spent nuclear fuel cask. Image: DOE

The Association of American Railroads (AAR) recently gave the Department of Energy approval to begin building and testing Fortis, a high-tech railcar designed specifically to transport the nation’s spent nuclear fuel and high-level radioactive waste. Fortis is one of two specialized railcars under development by the DOE that could be operational within the next five years.

Fortis is an eight-axle, flat-deck railcar that will be able to transport large containers of spent fuel and HLW. It is equipped with high-tech sensors and monitoring systems that report 11 different performance features back to the operators in real time. The railcar design was completed earlier this year, with technical support from Pacific Northwest National Laboratory.

According to the DOE, AAR signed off on the design in January, allowing the department to begin fabricating and testing the prototype in compliance with the rail industry’s highest design standard for railcars transporting spent fuel and HLW.