This is the fifth of five articles posted today to look back at the top news stories of 2021 for the nuclear community. The full article, "Looking back at 2021,"was published in the January 2022 issue of Nuclear News.

Quite a year was 2021. In the following stories, we have compiled what we feel are the past year’s top news stories from the October-December time frame—please enjoy this recap from a busy year in the nuclear community.

The Department of Energy has indefinitely delayed its final request for proposal (RFP) for the management and operations contract for the department’s Savannah River Site in South Carolina. The contract’s postponement was announced in a brief notice posted to the DOE’s Office of Environmental Management Consolidated Business Center website on November 9.

DOE liquid waste contractor Savannah River Remediation is moving forward with Saltstone Disposal Unit projects to support the Salt Waste Processing Facility at the Savannah River Site.

The Department of Energy’s Office of Environmental Management (EM) has authorized the use of a second mega-volume saltstone disposal unit (SDU) at the Savannah River Site in South Carolina. Savannah River Remediation (SRR), EM’s liquid waste contractor at SRS, received Critical Decision-4 for Saltstone Disposal Unit 7, marking the final step in the approval process before beginning operations.

SRNS's Communications and Media Services Department was honored with two 2021 Telly Awards. Members of the department include, from left, Robin Adney, Ian Rojas-Godoy, Brad Bohr, Nathan Lester, Steve Ashe, and Laura Russo. (Photo: DOE)

Along with established entertainment mediums such as Jennifer Garner’s “Pretend Cooking Show” and the Nickelodeon TV channel, Department of Energy contractor Savannah River Nuclear Solutions (SRNS) has been named a winner in two categories of this year’s Telly Awards.

SRNS’s Communications and Media Services Department won a Gold Telly for the video “Savannah River Site Overview” in the non-broadcast, corporate image category, and a Bronze Telly for “SRNS Now: September 2020” in the non-broadcast, employee communications category.

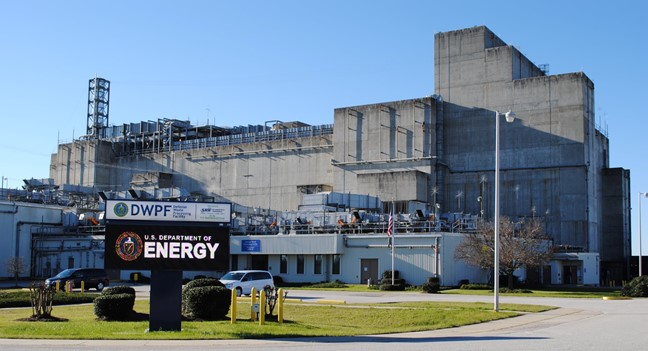

The Defense Waste Processing Facility at the Savannah River Site in South Carolina. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) has awarded Savannah River Mission Completion (SRMC), of Lynchburg, Va., the Integrated Mission Completion Contract at the Savannah River Site near Aiken, S.C. The single-award, master indefinite delivery/indefinite quantity contract has an estimated contract ceiling of approximately $21 billion over a 10-year ordering period, with cost-reimbursement and fixed-price task orders to define the contract performance.

Savannah River Remediation’s Mark Schmitz (left) and Denmark Technical College’s Willie L. Todd Jr. sign a memorandum of understanding to reaffirm the partnership between their respective organizations. (Photo: SRR)

Savannah River Remediation (SRR) and South Carolina’s Denmark Technical College (DTC) have renewed a memorandum of understanding that has a goal of preparing DTC students for work in the industrial and nuclear environment while also providing SRR with a potential pipeline of future employees.

SRR is the Savannah River Site’s liquid waste contractor, consisting of a team of companies led by Amentum, with partners Bechtel National, Jacobs, and BWX Technologies. Subcontractors include Orano, Atkins, and Amentum N&E Technical Services.

DTC is South Carolina’s only technical college that is also a historically black college or university.

Savannah River Remediation workers double-stack HLW canisters in an underground vault in Savannah River’s Glass Waste Storage Building 2 using a one-of-a-kind shielded canister transporter. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) has demonstrated the capability to expand the double-stacking of high-level waste canisters at the Savannah River Site in South Carolina. That approach will save the site’s cleanup program millions of dollars, according to the DOE.

U.S. Forest Service employees Secunda Hughes (left) and Andrew Thompson inspect irrigation piping and sprinkler heads, part of a 62-acre pine plantation used to safely disperse tritium at the Savannah River Site.

The Department of Energy’s Office of Environmental Management (EM) is managing the release of tritiated water using a 62-acre plantation of pine trees and other natural resources to limit radioactively contaminated groundwater from reaching waterways on the Savannah River Site in South Carolina.

F Area operator Thomas Harman (left) and SRNS scientist Kevin Boerstler check the pumps, sensors, and piping that blend a base concentrate to inject into acidic groundwater at the Savannah River Site. (Photo: DOE)

The Savannah River Site is reducing the flow of hazardous and radioactive metal contaminants to South Carolina’s rivers and streams by injecting a mix of clean water and baking soda into the site’s groundwater. The base mix neutralizes groundwater that has become acidic as a result of SRS’s chemical separations work, helping restrict the flow of contaminants.

Operators disassemble a cutter head inside a module at the Savannah River's Tritium Extraction Facility using manipulators and hand tools. (Photo: SRNS)

Using basic hand tools and remote manipulators, operators at Savannah River Nuclear Solutions (SRNS) were able to reduce radiation exposure to workers performing cutter head maintenance in the Savannah River Site’s Tritium Extraction Facility (TEF).

According to SRNS, the innovative procedure proved to be an excellent example of real-world application of As Low As Reasonably Achievable (ALARA) principles of time, distance, and shielding.

A view of Savannah River’s K Area Complex, where plutonium downblending operations take place. (Photo: DOE)

The Department of Energy’s Office of Environmental Management has doubled the number of work shifts for employees in glove box operations at its Savannah River Site in South Carolina. The increased work pace will help the department meet its commitment to South Carolina to remove surplus plutonium from the state, the DOE said.

From left, SRNS mechanic Todd Cockrell, engineer John Bradley, and project manager Joao Cardoso-Neto plan the removal of a vapor extraction unit at the Savannah River Site. (Photo: DOE)

Department of Energy site contractors Savannah River Nuclear Solutions and Savannah River Remediation received high marks from a recent independent audit of their environmental management work at the Savannah River Site in South Carolina.

A train pushes a container full of old equipment from H Canyon to a Savannah River Site disposal facility to make way for a new spent nuclear fuel dissolving campaign. (Photo: DOE)

The Department of Energy is preparing for an upcoming campaign to dissolve stainless-steel-clad spent nuclear fuel at its Savannah River Site in South Carolina by installing a new dissolver and an additional double-sized tank for storing dissolved material.

A virtual job fair for the Department of Energy’s Nuclear Security Enterprise (NSE) is being held on Wednesday, June 23, from 10 a.m. to 4 p.m. (EDT). The job fair will be hosted by the DOE's National Nuclear Security Administration.

The NSE is looking for the next generation of nuclear security professionals and is planning to hire more than 2,500 new employees in 2021.

Interested candidates are encouraged to register online for the event.

A view of the Savannah River Site’s Salt Waste Processing Facility. (Photo: DOE)

The Salt Waste Processing Facility at the Department of Energy’s Savannah River Site has performed largely as expected, processing more than one million gallons of radioactive waste during its first eight months of operation, the DOE reported on June 8. The SWPF is being used to treat the majority of the site’s remaining liquid radioactive waste, generated from the production of nuclear materials.

A salt dissolution campaign in Tank 37 at the Savannah River Site was completed ahead of schedule, creating tank space for evaporator operations and allowing for more feed to the Salt Waste Processing Facility. (Photo: DOE)

Department of Energy contractor Savannah River Remediation (SRR) announced on May 11 that it has completed a salt dissolution campaign in Tank 37, one of the underground tanks storing high-level radioactive liquid waste at the Savannah River Site (SRS) in South Carolina.

SRNS subcontractors Donald Miles and Richard Mooney drill for soil samples as part of a project to immobilize I-129 in the groundwater and soil at the Savannah River Site. Photo: DOE/SRNS

A silver chloride–based cleanup technology is expected to reduce radioactive iodine-129 contamination found in soil and groundwater near the center of the Department of Energy’s Savannah River Site in South Carolina to levels well below regulatory limits. The I-129 was created during the production of plutonium and tritium at the site throughout the Cold War era.

The Department of Energy’s Office of Environmental Management has released a draft request for proposals (RFP) for a new contract worth up to $21.5 billion over 10 years for the operation of the Savannah River Site in South Carolina. The draft RFP contemplates a standalone, performance-based, cost-plus-award-fee management and operating (M&O) contract containing discrete contract line-item numbers/specifications with the potential for other contract types.

SRNS engineers (from left) Will Jolin, John Bradley, and Joao Cardoso-Neto discuss a plan to move and repurpose equipment used at 19 soil cleanup sites. Photo: DOE

A project to passively remove nonradioactive contaminants from the soil and groundwater at the Department of Energy’s Savannah River Site in South Carolina is coming to an end, as workers prepare to remove solar-power “plugs” from 19 soil remediation locations at the site.

Crews move equipment used to inspect drums holding diluted plutonium into a storage site in K Area at the Savannah River Site. Photo: DOE

Workers at the Department of Energy’s Savannah River Site in South Carolina recently finished transferring equipment to the site’s K Area in preparation of shipping downblended plutonium to the Waste Isolation Pilot Plant in New Mexico for disposal. The plutonium is part of the 34 metric tons of surplus plutonium the National Nuclear Security Administration plans to ship to WIPP under the “dilute and dispose” option the department adopted following the cancellation of the MOX Fuel Fabrication Facility project.

and Andrew Thompson.jpg)