The Savannah River Site’s HB Line facility is located on top of the H Canyon chemical separations facility. (Photo: DOE)

The Department of Energy has announced that workers at its Savannah River Site in South Carolina recently removed legacy uranium materials from the site’s HB Line as part of an effort to clear the facility of its inventory of legacy nuclear materials. The removed legacy uranium was originally produced by the Y-12 National Security Complex at Oak Ridge, Tenn.

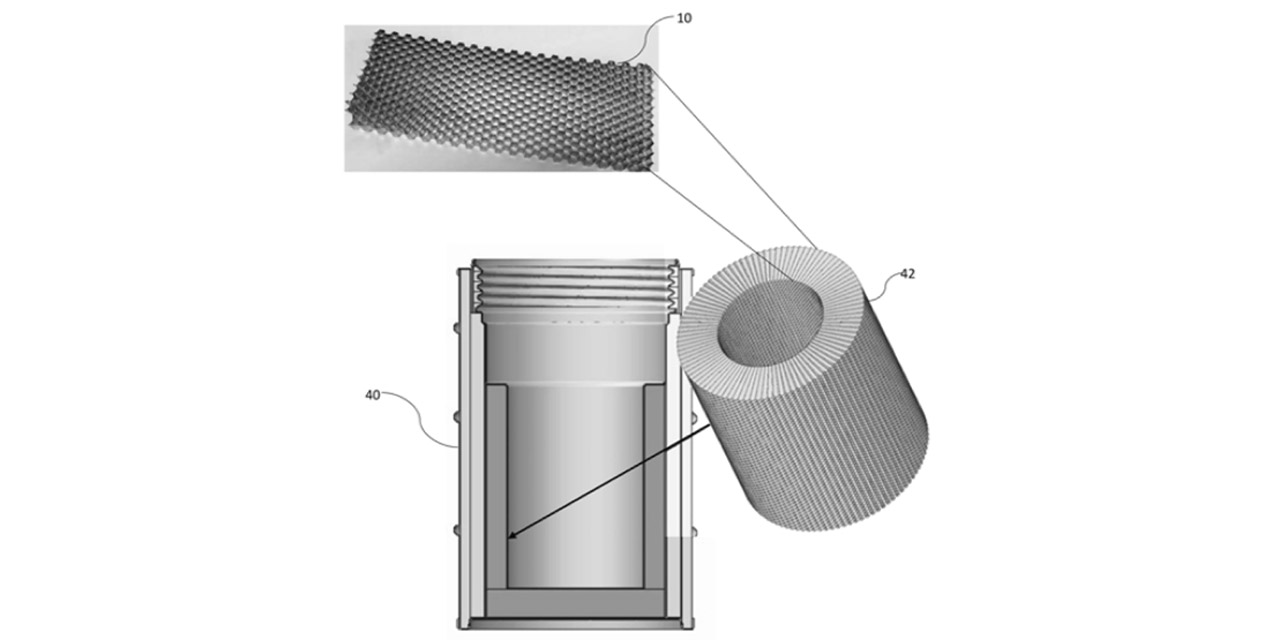

Illustration showing how radially oriented honeycomb structures can be used within a container to provide strength, sound insulation, or thermal insulation. The structure includes multiple radially aligned layers of a shaped strip. (Image: SRNL)

Savannah River National Laboratory said it has received a patent for its radially oriented honeycomb structures. The technology offers a solution to the deformation of cylindrical honeycomb structures when they are formed from flat panels, providing a way to create structures with greater wall thickness than traditional methods.

The Defense Waste Processing Facility at the Savannah River Plant. (Photo: SRS)

In 1989, the Savannah River Plant was renamed the Savannah River Site. It was originally established in 1950 near Aiken, S.C., to produce nuclear materials for the nation, primarily for defense purposes. The site consisted of a heavy water production plant, three fuel fabrication facilities, five production reactors, two nuclear separation facilities, waste management facilities, tritium processing facilities, and the Savannah River National Laboratory. The main isotopes produced were, by priority, tritium, plutonium-238, and plutonium-239.

Operators in plastic suits prepare for drum venting operations. (Photo: DOE/SRNS)

Department of Energy contractor Savannah River Nuclear Solutions (SRNS) said its Savannah River Site employees recently used an innovative method to ensure the integrity of radioactive material storage containers currently in long-term dry storage at the South Carolina site.

A close-up of the ALTEMIS monitoring device.

(Photo: Brad Bohr/SRNL)

Researchers at Savannah River National Laboratory (SRNL), in concert with Lawrence Berkeley National Laboratory, Massachusetts Institute of Technology, Pacific Northwest National Laboratory, and Florida International University, are leading the Advanced Long-Term Environmental Monitoring Systems (ALTEMIS) project to move groundwater cleanup from a reactive process to a proactive process, while also reducing the cost of long-term monitoring and accelerating site closure.

Savannah River National Laboratory employee Vernon Bush, center, and SRNL summer intern Jadrion Huell, standing at right, of Claflin University, conduct a job shadowing activity with students Tredarius Lassiter, seated at left, and Tommy Applewhite. (Photo: DOE)

A three-day Minority Serving Institutions Partnership Program (MSIPP) event, led by Savannah River National Laboratory researcher Simona Hunyadi Murph, was held recently at the South Carolina site, according to a release by the Department of Energy’s Office of Environmental Management (DOE-EM). The event included a collaborative workshop, job shadowing, and a tour of the laboratory and Savannah River Site field activities.

Augusta University’s Neil MacKinnon and SRNL’s Tammy Taylor at the signing ceremony for a new security and workforce development partnership.

Savannah River National Laboratory and Augusta University have announced a new agreement that formalizes a long-standing partnership and expands on a shared mission to address global security issues.

Panelists speak at the 2023 Waste Management Symposia “Hot Topics” session. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) has made great progress in accomplishing its cleanup of legacy radioactive waste but has yet to tackle its most challenging tasks, including the treatment of liquid tank waste at the Hanford, Idaho, and Savannah River sites. That was the consensus of the DOE-EM officials who took part in a panel session of the 2023 Waste Management Symposia, held February 26–March 2 in Phoenix, Ariz.

Using GeoMelt ICV technology to treat and immobilize problematic low-level wastes at INL and WCS.

A sample of GeoMelt glass. (Photos: Veolia)

When it comes to managing nuclear waste, technology is transforming the way some of the most problematic waste is handled. The idea to transform nuclear waste into glass was developed back in the 1970s as a way to lock away the waste’s radioactive elements and prevent them from escaping. For more than 40 years, vitrification has been used for the immobilization of high-level radioactive waste in many countries around the world, including the United States.

Savannah River’s DWPF has completed the conversion from formic acid to glycolic acid in the waste vitrification process. (Photo: DOE)

The Defense Waste Processing Facility (DWPF) at the Department of Energy’s Savannah River Site (SRS) in South Carolina has resumed operations after a completing a processing improvement that the DOE said will enable safer operations and more efficient vitrification of radioactive waste.

This still image, taken from a General Fusion video, depicts the demo plant that will be built near Oxford, U.K. (Image: General Fusion)

Canadian Nuclear Laboratories (CNL) and General Fusion have announced a memorandum of understanding (MOU) to “develop fusion energy research capabilities within CNL, to support the goal of constructing a potential General Fusion commercial power plant in Canada before 2030.” The plant would follow on a demonstration-scale plant that General Fusion wants to have operating in the United Kingdom by 2027 to validate the performance and economics of the technology.

Nicholas Spivey, left, an SRNL mechanical engineer, and Kurt Gerdes, director of EM’s Office of Technology Development, use virtual reality simulation of an EM worksite during meetings held at the IHMC in Pensacola, Fla. (Photo: DOE)

For the first time since forming in 2020, more than 40 members of a Department of Energy team met in person to evaluate technologies, including exoskeletons and wearable robotic devices, that could be adapted to the cleanup mission of department’s Office of Environmental Management (EM), helping improve the safety and well-being of its workers.

Rep. Jamaal Bowman during a hearing of the House Science, Space, and Technology Subcommittee on Energy.

The House Science, Space, and Technology Subcommittee on Energy held a hearing last week to evaluate the Department of Energy’s approach to research and development on new strategies and technologies to support the nuclear waste cleanup mission of its Office of Environmental Management (EM).