The Savannah River Site’s shielded canister transporter. (Photo: DOE)

The large vehicle used to transport highly radioactive canisters at the Department of Energy’s Savannah River Site has completed a pit stop to ensure the continued movement of the site’s radioactive liquid waste work.

A tanker holding 6200 gallons of leachate unloads at a backup load-in station at the Hanford Site’s ETF. (Photo: DOE)

Construction of a backup load-in station has been completed at the Hanford Site’s Effluent Treatment Facility (ETF) in Washington state.

“We broke ground on the backup facility about a year ago,” said Rob Wood, project manager for Washington River Protection Solutions, the Department of Energy’s tank operations contractor at the site. “I am proud of the team for completing this portion of the load-in expansion project and doing it safely. In phase two, expansion of the main load-in station will prepare us for 24/7 operations on the Hanford Site.”

Watch a time-lapse video of the backup load-in station construction here.

The Panther T16 sprays fixative with a high-pressure water cannon onto X-326 building debris at the Portsmouth Site. (Photo: DOE)

Workers at the Department of Energy’s Portsmouth Site in Ohio have been using a new tool as part of the dust-suppression systems for the X-326 process building demolition project. The X-326 was one of three massive process buildings originally built to enrich uranium at the site, which was in operation starting in the 1950s. Environmental remediation of the site began in 1989, and deactivation and decommissioning activities began in 2011. Demolition of the facility has led to a dusty work environment.

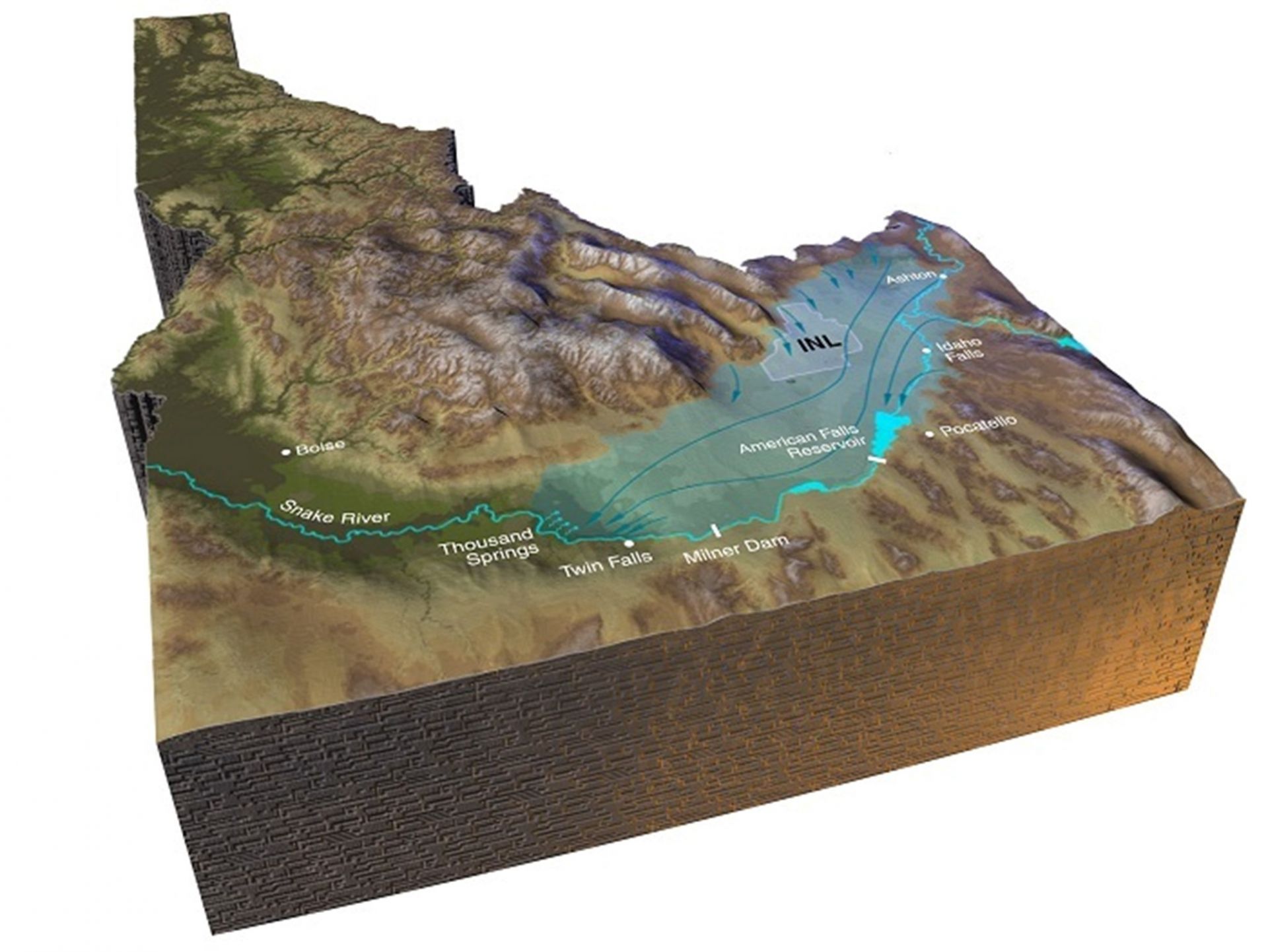

The underlying Snake River Plain Aquifer is considerably safer today following three decades of cleanup activities at the DOE’s Idaho National Laboratory Site. (Graphic: DOE)

When the Department of Energy, the state of Idaho, and the Environmental Protection Agency signed a federal facility agreement and consent order in December 1991, the agencies outlined a plan to investigate and clean up, if necessary, more than 500 individual waste areas within the 890-square-mile Idaho National Laboratory (INL) Site, which was established in 1949 to design, build, and test nuclear reactors.

A truck loaded with waste crosses the scale at the East Tennessee Technology Park at Oak Ridge. Each truck used by Oak Ridge contractor UCOR is equipped with a unique radio frequency identification card that logs its movements and weight and registers the data in a database.

UCOR, the primary contractor for the Department of Energy’s Oak Ridge Office of Environmental Management (OEM), recently transitioned to a new waste tracking system that improves how shipments are tracked from work sites to disposal locations.

The new system includes upgraded radio frequency identification (RFID) tracking for trucks, as well as new hardware and software, allowing for an automated tracking operation that delivers up-to-the-minute waste disposal data.