The DUF6 facility at the Paducah Site in Kentucky. (Photo: DOE)

The Department of Energy’s Office of Environmental Management has awarded a $2.3 billion operations and site mission support services contract for the Portsmouth Paducah Project Office (PPPO) to Mission Conversion Services Alliance (MCSA), a limited liability company made up of Atkins Nuclear Secured, Westinghouse Government Services, and Jacobs Technology, with Swift & Staley and Akima Centerra Integrated Services as teaming subcontractors.

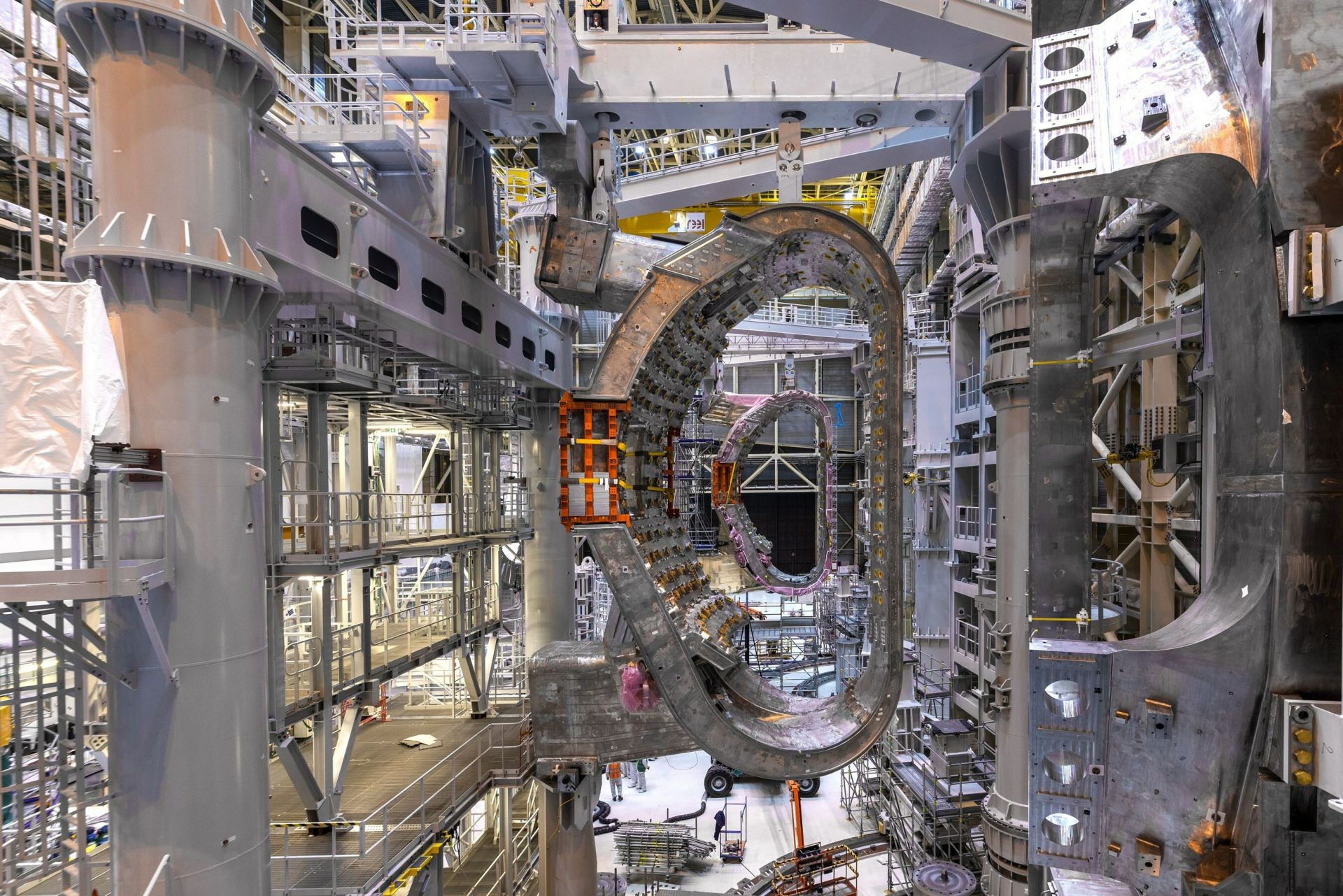

Inside the ITER tokamak assembly hall. (Photo: ITER Organization)

The engineering company Jacobs announced last week that it has been awarded a four-year contract to design and engineer remotely operated tools for the ITER fusion project in southern France. The contract, which includes a possible two-year extension, covers work on up to 25 diagnostic ports and systems used for operating and sustaining the ITER experimental machine, which is currently under construction.

The Ignalina nuclear power plant. (Photo: INPP)

A consortium comprising Westinghouse Electric Spain, Jacobs, and the Lithuanian Energy Institute has been selected to plan dismantling and waste management at the long closed two-unit Ignalina nuclear power plant in Lithuania.

The Snake River Plain Aquifer

The Department of Energy’s Office of Environmental Management will award the Idaho Cleanup Project contract for the Idaho National Laboratory site to Idaho Environmental Coalition (IEC), of Tullahoma, Tenn. The contract has an estimated ceiling of approximately $6.4 billion over 10 years, with cost reimbursement and fixed-price task orders to define the contract performance.

Workers remove asbestos siding panels from a Portsmouth Gaseous Diffusion Plant building. Photo: Business Wire

Fluor-BWXT Portsmouth, a joint venture of Fluor and BWX Technologies, along with engineering company Jacob, have received a contract extension valued at up to $690 million, including options, from the Department of Energy. The contract, announced April 6, is for environmental management work at the former Portsmouth Gaseous Diffusion Plant near Piketon, Ohio.

A systematic analysis of drivers and barriers of cross-sectorial learning between nuclear and oil and gas decommissioning projects.

October 2, 2020, 3:39PMRadwaste SolutionsDiletta Colette Invernizzi, Nick Higginson, Richard Howells, Willem Van Es, and Ian Beadle The Deepsea Delta oil-drilling platform in the North Sea. The dismantling of such large oil and gas structures may offer lessons that can be applied to nuclear decommissioning.

Within the energy sector, the management of projects and megaprojects has historically focused on the planning and delivery of the construction of infrastructure [1–3]. Therefore, policies are more oriented to support the construction of infrastructure rather than its decommissioning. Globally, however, a number of facilities have reached or will soon reach their end of life and need to be decommissioned.

These facilities span the energy sector, including nuclear power plants, oil and gas rigs, mines, dams, etc., whose decommissioning present unprecedented technical and socioeconomic challenges [4–7]. Moreover, the cost of decommissioning and waste management of this array of infrastructure is estimated to reach hundreds of billions of dollars and, for most of these projects, keeps increasing, with limited cross-sectorial knowledge-transfer to mitigate the spiraling increase of these figures.

Cross-sectorial knowledge-transfer is one way to tackle this matter and improve the planning and delivery of decommissioning projects. The aim of our research has been to build a roadmap that is designed to promote the sharing of good practices between projects both within the same industry and across different industrial sectors, focusing specifically on major decommissioning and waste-management challenges.

To reach this aim, our research leverages on the experience of senior industry practitioners and their involvement in the decommissioning and waste management of infrastructure in different sectors. More specifically, this research addresses the following questions:

To what extent can lessons learned be transferred across industrial sectors?

What are the challenges that hinder successful cross-sectorial knowledge-transfer?