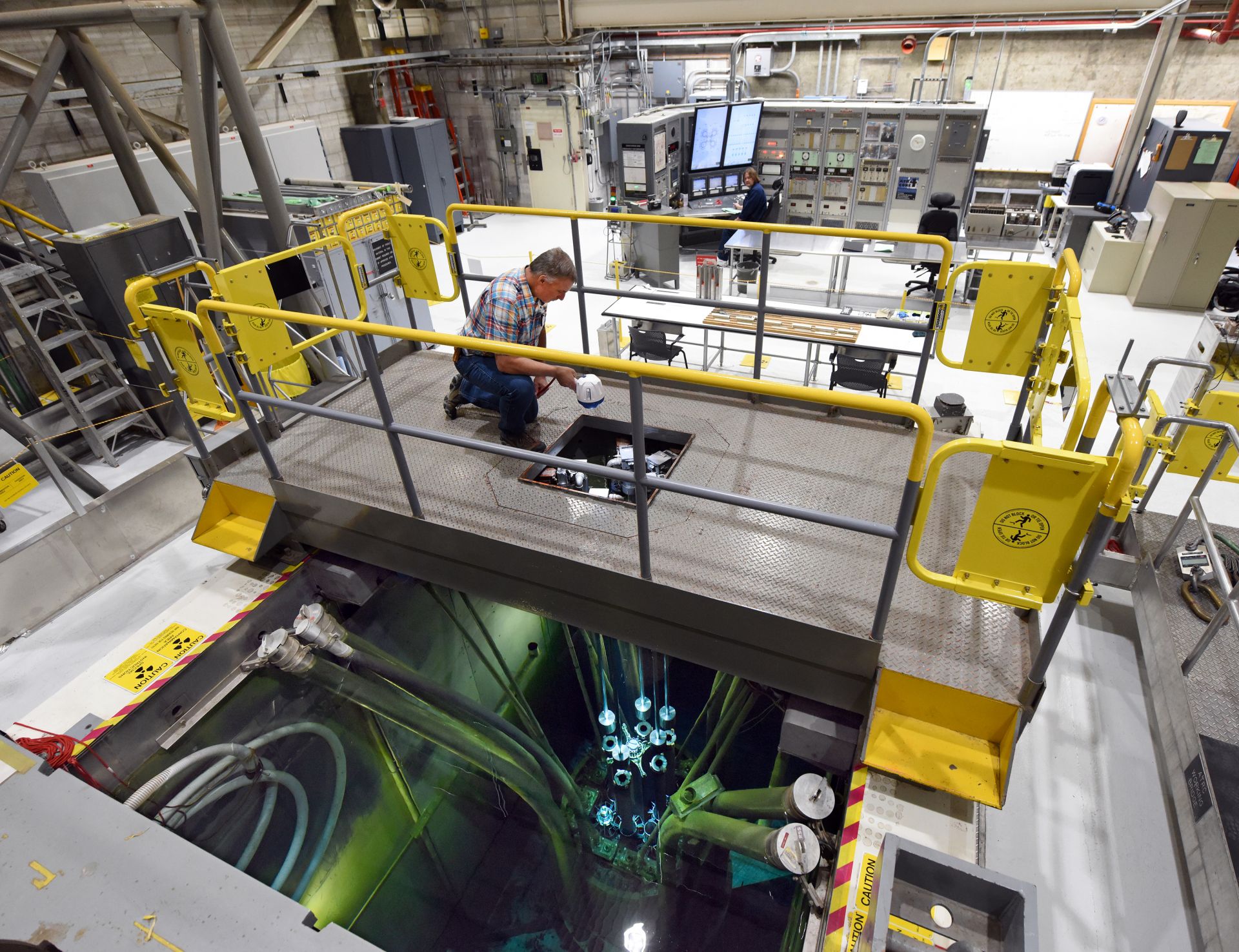

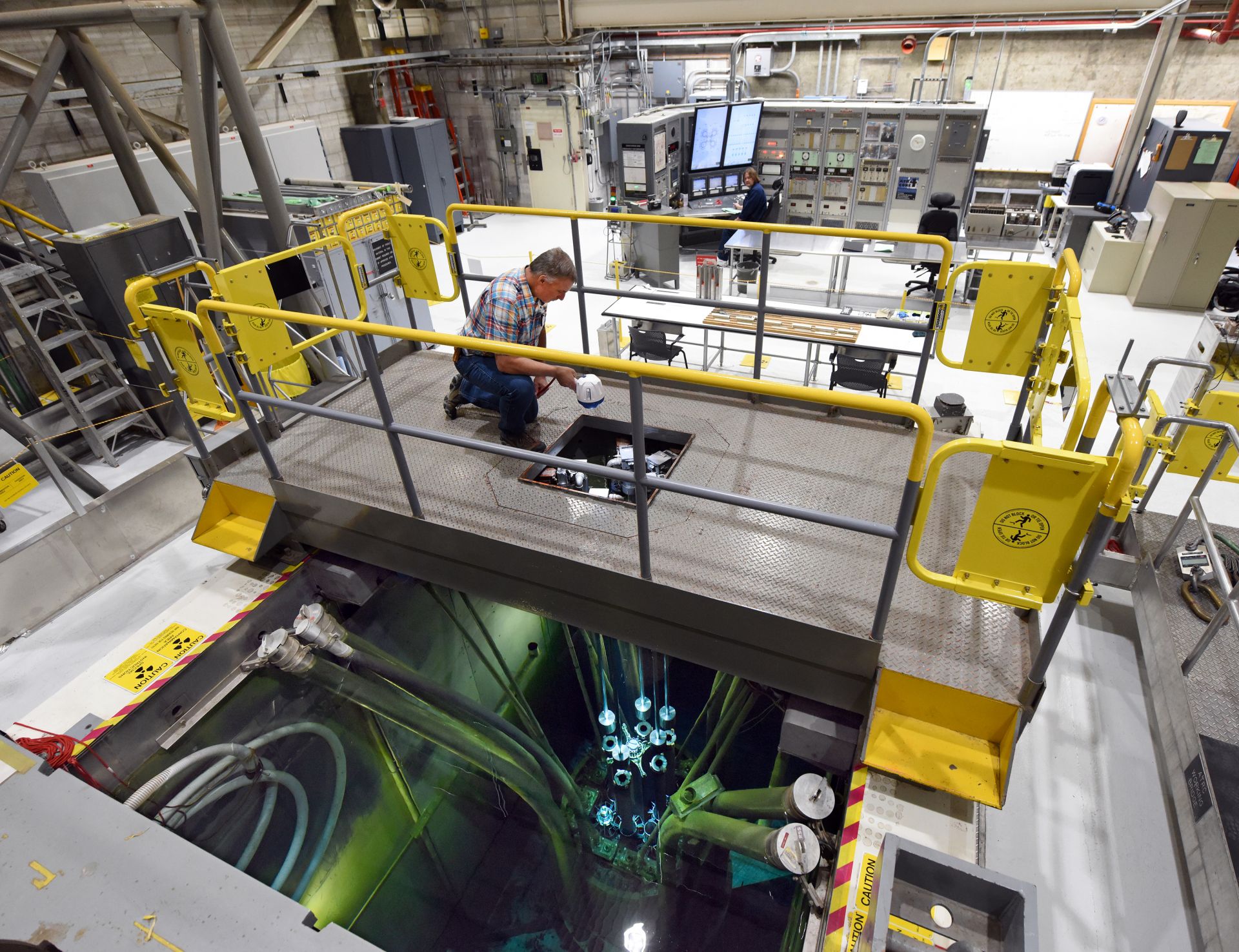

Idaho’s ATR Critical Facility undergoes a digital control system upgrade.

Reactor operators Craig Winder (foreground) and Clint Weigel prepare to start up the ATRC Facility reactor at Idaho National Laboratory after a nearly two-year project to digitally upgrade many of the reactor’s key instrumentation and control systems.

Photos: DOE/INL

At first glance, the Advanced Test Reactor Critical (ATRC) Facility has very little in common with a full-size 800- or 1,000-MW nuclear power reactor. The similarities are there, however, as are the lessons to be learned from efforts to modernize the instrumentation and control systems that make them valuable assets, far beyond what their designers had envisioned.

One of four research and test reactors at Idaho National Laboratory, the ATRC is a low-power critical facility that directly supports the operations of INL’s 250-MW Advanced Test Reactor (ATR). Located in the same building, the ATR and the ATRC share the canal used for storing fuel and experiment assemblies between operating cycles.

The U.S. Department of Energy’s Light Water Reactor Sustainability Program, led by Idaho National Laboratory, works closely with utilities to improve outage efficiencies and enable nuclear to go “toe-to-toe economically” with other energy sources.

Working in INL’s Human Systems Simulation Laboratory, senior R&D scientist Ahmed Al Rashdan co-developed the Advanced Remote Monitoring project for the LWRS Program.

There are numerous similarities between auto racing pit crews and the people in the nuclear power industry who get us through outages: Pace. Efficiency. Diagnostics. Teamwork. Skill. And safety above all else.

To Paul Hunton, a research scientist at Idaho National Laboratory, the keys to successfully navigating a nuclear plant outage are planning and preparation. “When you go into an outage, you are ready,” Hunton said. “You need to manage outage time. You want to avoid adding delays to the scheduled outage work because if you do, it can add a couple million dollars to the cost.”

Hunton was the principal investigator for the September 2019 report Addressing Nuclear Instrumentation and Control (I&C) Modernization Through Application of Techniques Employed in Other Industries, produced for the U.S. Department of Energy’s Light Water Reactor Sustainability (LWRS) Program, led by INL. Hunton drew on his experience outside the nuclear industry, including a decade at Newport News Shipbuilding.

Digital engineering, which uses advanced technologies to capture data and optimize design in a digital environment, is being applied for the first time to a DOE nuclear project and has already realized substantial benefits.

With a new generation of nuclear reactors in the works, Idaho National Laboratory has embraced digital engineering (DE) as a means of achieving the same efficiencies that companies in the private sector have been able to realize in everything from concert halls to aircraft engines.

DE—using advanced technologies to capture data and craft design in a digitized environment—has been evolving since the 1990s. For Mortenson Construction, a worldwide construction firm, using virtual design and construction resulted in a cumulative 600 days saved over 416 projects and a 25 percent increase in productivity. By building digital twins for assets, systems, and processes, DE has avoided more than $1.05 billion in customer, production, and mechanical losses.

Leaders at INL recognized in 2018 that DE could be useful in the design and construction of new commercial and test reactors. Managing construction costs, timing, and performance will be essential to maintain U.S. competitiveness.

The nuclear industry has embraced the risk-informed and performance-based (RIPB) decision-making process over the past two decades. Still, it remains a complex concept to explain in lay terms.

The nuclear industry has embraced the risk-informed and performance-based (RIPB) decision-making process over the past two decades. Still, it remains a complex concept to explain in lay terms.

There’s a new mythbuster out in the Idaho desert by the name of Don Miley, separating nuclear fact from fiction in the service of science and the Idaho National Laboratory. An article released by INL’s Communications and Outreach staff on August 3—“

There’s a new mythbuster out in the Idaho desert by the name of Don Miley, separating nuclear fact from fiction in the service of science and the Idaho National Laboratory. An article released by INL’s Communications and Outreach staff on August 3—“