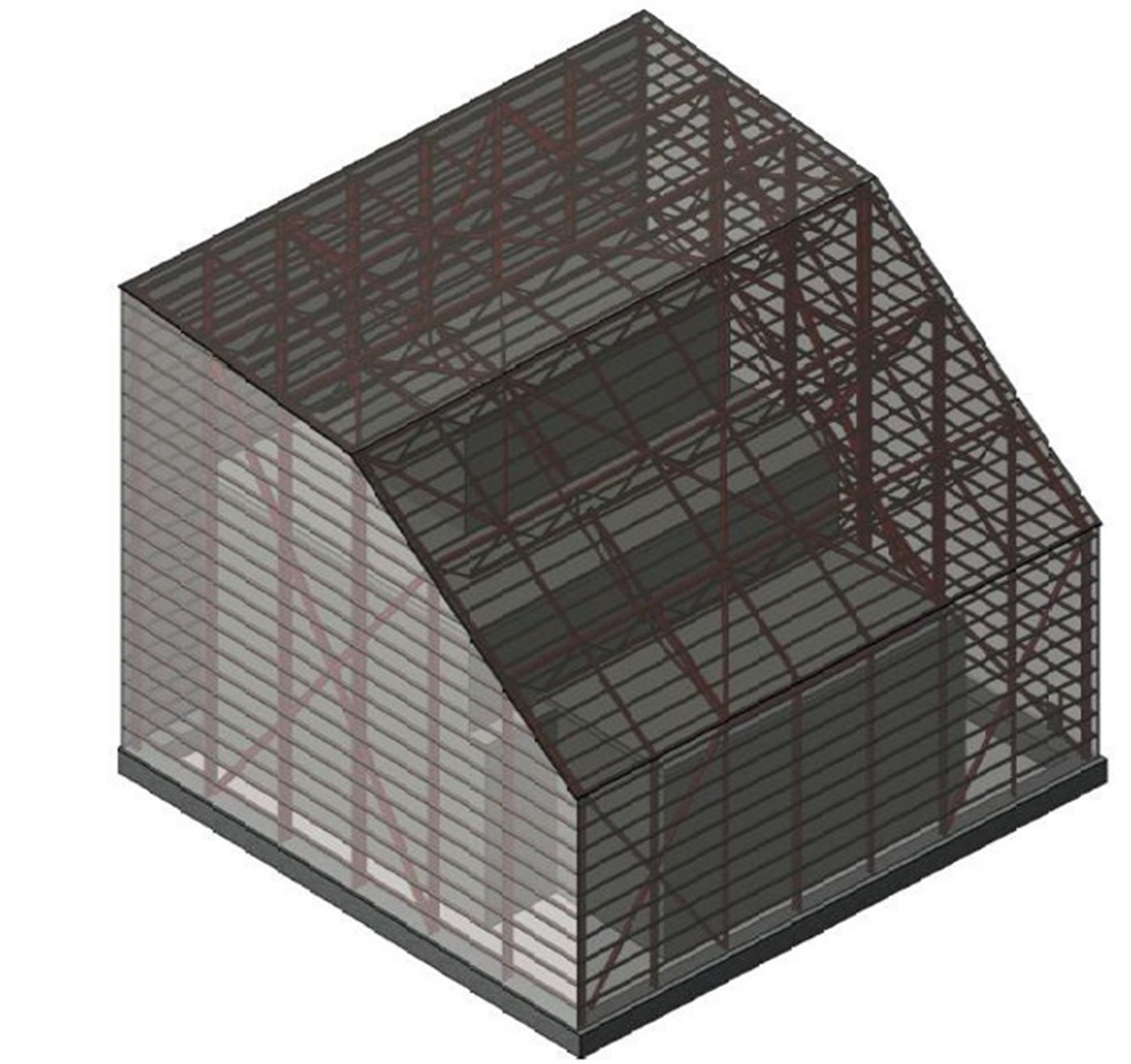

An artist’s rendering of the K East Reactor safe-storage enclosure. (Photo: DOE)

Preparations are being made to enclose, or “cocoon,” the K East Reactor, the seventh of nine former reactors at the Department of Energy’s Hanford Site. The cocooning project is expected to be completed by the end of the year.

Watch this video for more on the project.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

Workers recently installed manipulator equipment at a full-scale mock-up of areas of the Hanford Site’s Waste Encapsulation and Storage Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced this week that preparations are well underway for the transfer of nearly 2,000 highly radioactive cesium and strontium capsules from the Waste Encapsulation and Storage Facility (WESF) to interim dry storage at the Hanford Site near Richland, Wash.

Employees wearing supplied-air equipment work through clues in an “escape room” during respiratory protection training at Hanford’s Volpentest HAMMER Federal Training Center. (Photo: DOE)

A new respiratory protection course at the Department of Energy’s Hanford Site near Richland, Wash., features an “escape room” in which employees wear supplied-air equipment while they answer questions, discover clues, and solve puzzles in a simulated work environment.

September 10, 2021, 8:22AMUpdated December 31, 2021, 7:15AMNuclear NewsThomas R. Wellock An aerial view of the Hanford reservation and Columbia River that shows the N (nearest), KE/KW (center), and B (top right) reactors. (Photo: U.S. DOE )

In March 1972, Stephen Hanauer, a technical advisor with the Atomic Energy Commission, met with Norman Rasmussen, a nuclear engineering professor at the Massachusetts Institute of Technology. The AEC had recruited Rasmussen to develop a report, The Reactor Safety Study (WASH-1400), to estimate the probabilities and consequences of a major nuclear power plant accident. With thousands of safety components in a modern reactor, the task was mind-boggling. Rasmussen proposed a novel approach based on more powerful computers, “fault tree” methodology, and an expanding body of operational data. By calculating and aggregating probabilities for innumerable failure chains of components, he believed he could develop a meaningful estimate of overall accident risk. WASH-1400 would be a first-of-its-kind probabilistic risk assessment (PRA).

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.

Electrician Ralph Bisla conducts tests of the finishing line inside Hanford’s WTP Low-Activity Waste Facility. (Photo: DOE)

Having completed all startup testing of components and systems, the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site near Richland, Wash., has moved to the commissioning phase, the Department of Energy’s Office of Environmental Management (EM) announced last week. During the commissioning phase, the final steps will be taken to prepare for the vitrification of radioactive and chemical waste as part of Hanford’s Direct-Feed Low-Activity Waste (DFLAW) program.

Crews pump waste from Hanford’s single-shell tanks to more stable double-shell tanks. (Photo: DOE)

The Department of Energy is considering solidifying 2,000 gallons of Hanford’s tank waste and disposing of it as low-level radioactive waste at an off-site facility. A virtual public meeting on the proposed disposal plan is scheduled for November 18.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management (EM) has issued a final request for proposal (RFP) for the Hanford Integrated Tank Disposition Contract, a 10-year, $45 billion deal to oversee waste tank operations at the DOE’s Hanford Site near Richland, Wash. Proposals are due by December 20.

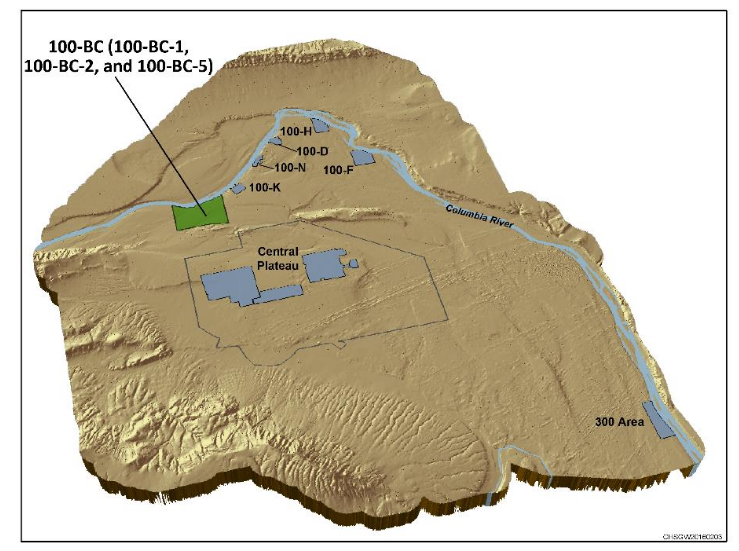

The 100-BC Area (in green) within the Hanford Site. (Image: DOE)

Soil and groundwater contamination at the Hanford Site’s 100-BC Area will be treated under a record of decision (ROD) signed by the Department of Energy and the Environmental Protection Agency, with the concurrence of the Washington State Department of Ecology.

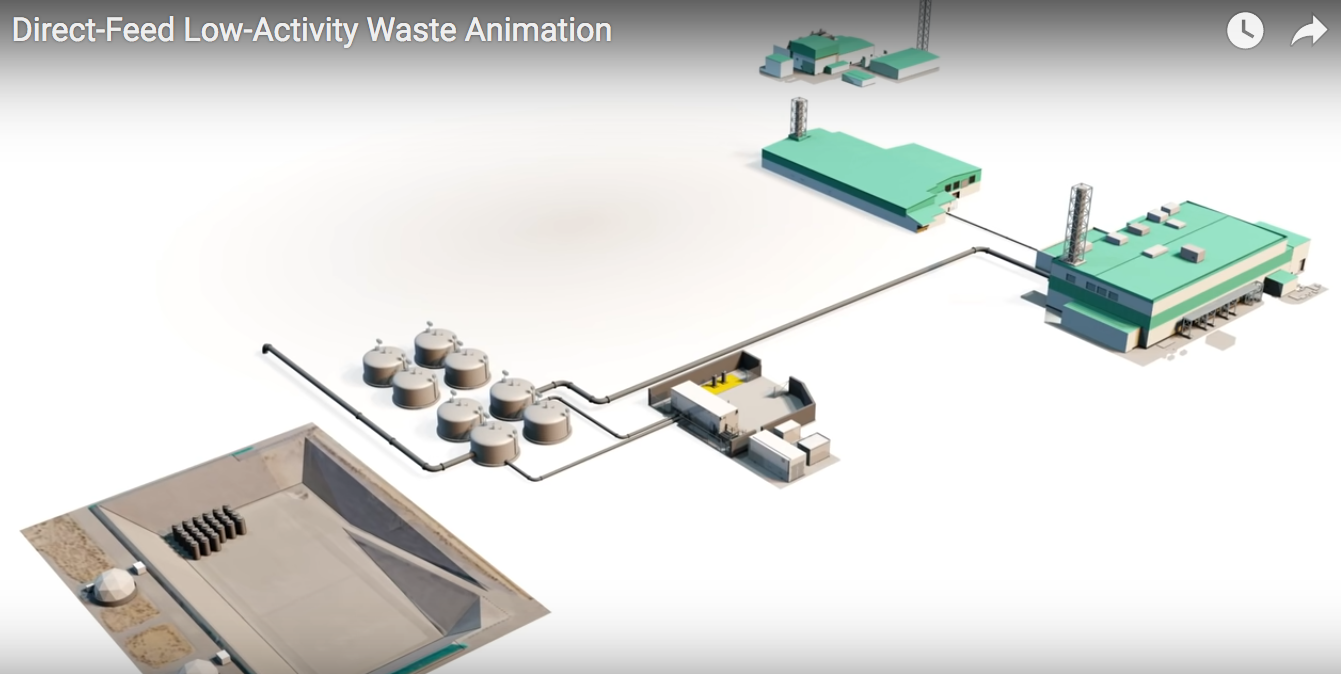

A screen shot from Hanford’s DFLAW animation. (Image: DOE)

The Department of Energy’s Office of Environmental Management (EM) has released an animated video of the Direct-Feed Low-Activity Waste (DFLAW) Program at the Hanford Site near Richland, Wash. The video shows the integrated procedure for treating Hanford’s radioactive tank waste, a process EM says is a key component of its strategic cleanup vision.

View the animation here.

Nitya Chandran, a facility engineer with the Washington State Department of Ecology, inspects Hanford’s tank-side cesium removal system. (Photo: DOE)

Washington state and Oregon will receive approximately $33.5 million through four financial assistance grants from the Department of Energy to fund programs related to the cleanup of the department’s Hanford Site near Richland, Wash. The grants will support environmental response regulatory activities, emergency preparedness, and public information programs in the two states.

All four grants, which were noncompetitively awarded, are for fiscal years 2022 through 2026.

Hanford workers fit sections of double-walled pipe in place, connecting the site’s tank farms to the Waste Treatment and Immobilization Plant. (Screen shot: WRPS/YouTube)

The Department of Energy is celebrating a major milestone in its tank waste mission at the Hanford Site near Richland, Wash. DOE tank operations contractor Washington River Protection Solutions has finished construction of the pipeline that will carry treated waste from an underground tank to the Waste Treatment and Immobilization Plant (WTP) for vitrification.

An artist’s rendition of the K East Reactor safe-storage enclosure. (Image: DOE)

DGR Grant Construction will construct a safe-storage enclosure over the K East Reactor building at the Department of Energy’s Hanford Site in Washington state. Two construction subcontracts, worth about $9.5 million, were awarded to the Richland, Wash.–based company by Central Plateau Cleanup Company, the DOE’s Richland Operations Office site cleanup contractor.

The DOE recently completed startup testing on the uninterruptable electrical power system for Hanford’s Low-Activity Waste Facility.

Department of Energy workers recently finished startup testing of a battery-powered backup electrical system for the Low-Activity Waste (LAW) Facility at the Hanford Site near Richland, Wash. According to the DOE’s Office of Environmental Management (EM), the uninterruptable electrical power system is vital to safeguarding the facility, part of Hanford’s Waste Treatment and Immobilization Plant, in the unlikely event of a temporary power loss to the plant.

An undated historical photo of a portion of the Hanford Site. (Photo: DOE)

The Department of Energy's Office of River Protection and the Richland Operations Office hosted a roundtable discussion recently with tribal nations located near the Hanford Site to review the Department’s tribal government policy—Order 144.1, the American Indian and Alaska Native Tribal Government Policy—and discuss opportunities for strengthening tribal consultation.

The Office of River Protection is within the purview of the DOE's Office of Environmental Management (EM). The Hanford Site, in eastern Washington state, is a 586-square-mile site that was used as a nuclear production complex during the World War II era.

A loaded waste container at the site of the former Plutonium Finishing Plant is surveyed to ensure that it is safe for transfer to Hanford’s on-site disposal facility. (Photo: DOE)

Final cleanup activities at the Hanford Site’s demolished Plutonium Finishing Plant have resumed following a pause in work prompted by the COVID-19 pandemic, the Department of Energy announced. Crews with the DOE’s Richland Operations Office and site contractor Central Plateau Cleanup Company will remove, package, and dispose of rubble remaining from the demolition of the plant’s plutonium reclamation facility, which was torn down in 2017.

Ray Geimer with DOE contractor Central Plateau Cleanup Company, left, shows company president Scott Sax a mock-up of parts of a vertical pipe casing system at Hanford’s Maintenance and Storage Facility. Photo: DOE

Workers at the Department of Energy’s Hanford Site near Richland, Wash., recently completed testing a mock-up of a system that will be used to isolate and stabilize about 15,000 pounds of radioactive debris in the site’s K West Reactor spent fuel storage basin.

The B Complex area tank farm at the DOE’s Hanford Site in Washington. Photo: DOE

The Department of Energy announced that it has determined that an underground single-shell waste tank at its Hanford Site near Richland, Wash., is likely leaking into the soil beneath the tank. The DOE said that the leaking tank poses no increased health or safety risk to the Hanford workforce or the public.

within the Hanford Site.png)