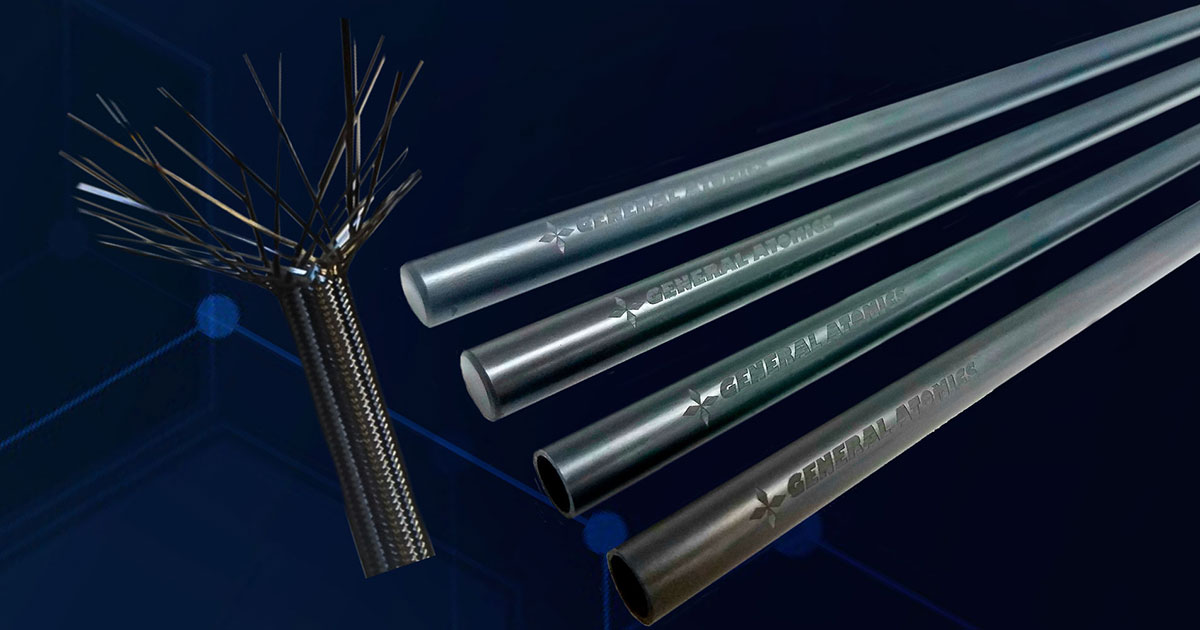

(Image: General Atomics Electromagnetic Systems)

General Atomics Electromagnetic Systems (GA-EMS) announced last week that unfueled test rods featuring the company’s SiGA fuel cladding—made of a silicon carbide composite material—successfully survived 120 days of irradiation in the Advanced Test Reactor (ATR) at Idaho National Laboratory.

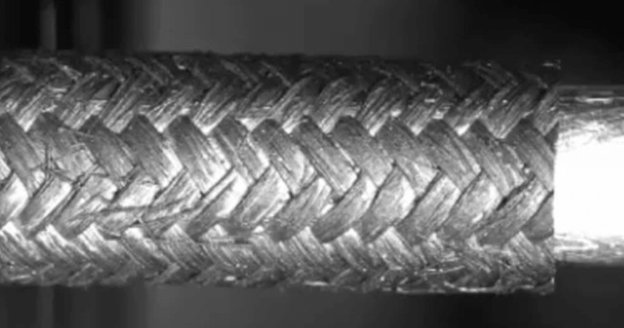

SiGA woven silicon carbide nuclear fuel cladding. (Photo: DOE)

Because of its hardness and its hardiness in the face of high temperatures, silicon carbide has been used for industrial purposes for decades. It has proven its worth as a key component of tiny TRISO fuel particles. But SiC has a weakness—in its pure form it is too brittle for use in structural components, such as 12-foot-long light water reactor fuel cladding tubes.

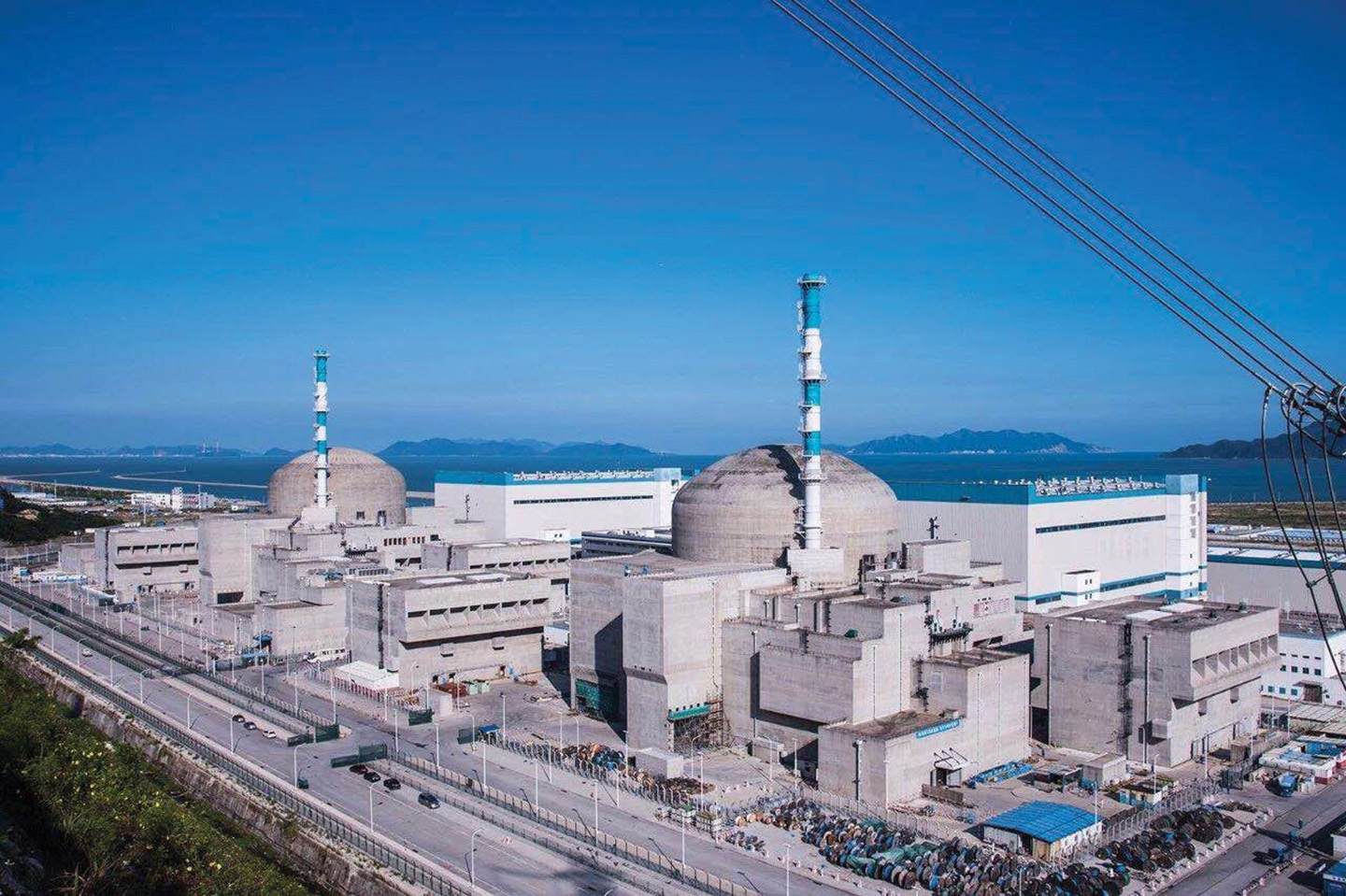

The Taishan nuclear power plant in China. (Photo: CGN)

China’s Taishan-1, which was shut down last summer due to damaged fuel rods, resumed operations on August 15.

The plant briefly made headlines last summer—as much for the damage inside the reactor as for the media fallout. In June 2020, plant operators found damage to the cladding on about five of the 60,000 fuel rods in Taishan-1, one of the plant’s two 1,660-MW EPRs. What happened next seemed like a bad game of “telephone.”

Taishan nuclear power plant. (Photo: EDF Energy)

If Taishan-1 were operating in France, Électricité de France would shut down the reactor in order to assess the situation in progress and stop its development, according to a July 22 press release from EDF. The 1,660-MWe French-designed EPR—the recent subject of sensational press coverage of fuel rod failures—operates in China’s Guangdong Province.

Taishan’s Unit 1 was the world’s first EPR to be connected to the grid. (Photo: CGN)

The facts, once known, were uncomplicated. At Taishan-1 in China—the first Framatome EPR to be commissioned—operators detected an increase of fission product gases within the primary coolant circuit sometime after the reactor’s first refueling outage in October 2020. The cladding on a handful of the more than 60,000 fuel rods in the reactor had been breached, posing an operational issue—but not a public safety issue—for the plant.