Korea’s KSTAR tokamak. (Photo: Korea Institute of Fusion Energy)

Aggregate is delivered by rail to the U.K.’s Low-Level Waste Repository site. (Photo: NWS)

Nuclear Waste Services (NWS), which manages the disposal of the United Kingdom’s low-level radioactive waste, announced this week that a major milestone has been reached at its Low Level Waste Repository in West Cumbria, England, as work begins on the final capping of legacy disposal trenches and vaults at the site.

The Oyster Creek ISFSI. (Photo: Holtec International)

The Tax Court of New Jersey has ruled that Oyster Creek’s spent nuclear fuel storage casks are subject to taxation as real property.

February 26, 2025, 9:30AMUpdated February 26, 2025, 9:30AMNuclear NewsEd Warman Ed Warman in 1990 (left), when he was named an ANS Fellow, and in 2019 (right) with a great-granddaughter, who is wearing a Soviet hat that was bought from a Russian soldier the day before the Red Army evacuated Prague in 1991.

We welcome ANS members with long careers in the community to submit their own stories so that the personal history of nuclear power can be capured. For information on submitting your stories, contact nucnews@ans.org.

When I graduated from Scranton University in 1956 with a B.S. in physics, I was in awe of the nuclear era and determined to be part of a nuclear future. Fortunately, I landed a position with Pratt & Whitney Aircraft as part of the Aircraft Nuclear Propulsion program. The position included a one-year assignment as a visiting staff member at Oak Ridge National Laboratory.

The nuclear fuel reprocessing plant product store at Sellafield. (Photo: NDA)

The United Kingdom’s Nuclear Decommissioning Authority has announced that it will establish a Plutonium Ceramics Academic Hub with the Universities of Manchester and Sheffield. The announcement follows a decision by the U.K. government in January to immobilize the country’s inventory of civil separated plutonium at the Sellafield nuclear site, mitigating the material’s long-term safety and security risks.

A rendering of Holtec’s dual-unit SMR-300. (Image: Holtec)

Leaders from Holtec International and Hyundai Engineering & Construction gathered at the Palisades site in western Michigan today to announce an “expanded cooperation agreement” to build a 10-GW fleet of Holtec-designed SMR-300s in North America. That fleet’s first builds would be at Palisades, where Holtec is now focused on restarting the site’s shuttered 777-MWe pressurized water reactor by the end of this year. Under the “Mission 2030” plan launched today, Holtec would then build a pair of SMR-300 PWRs at the Palisades site—targeting operation in 2030.

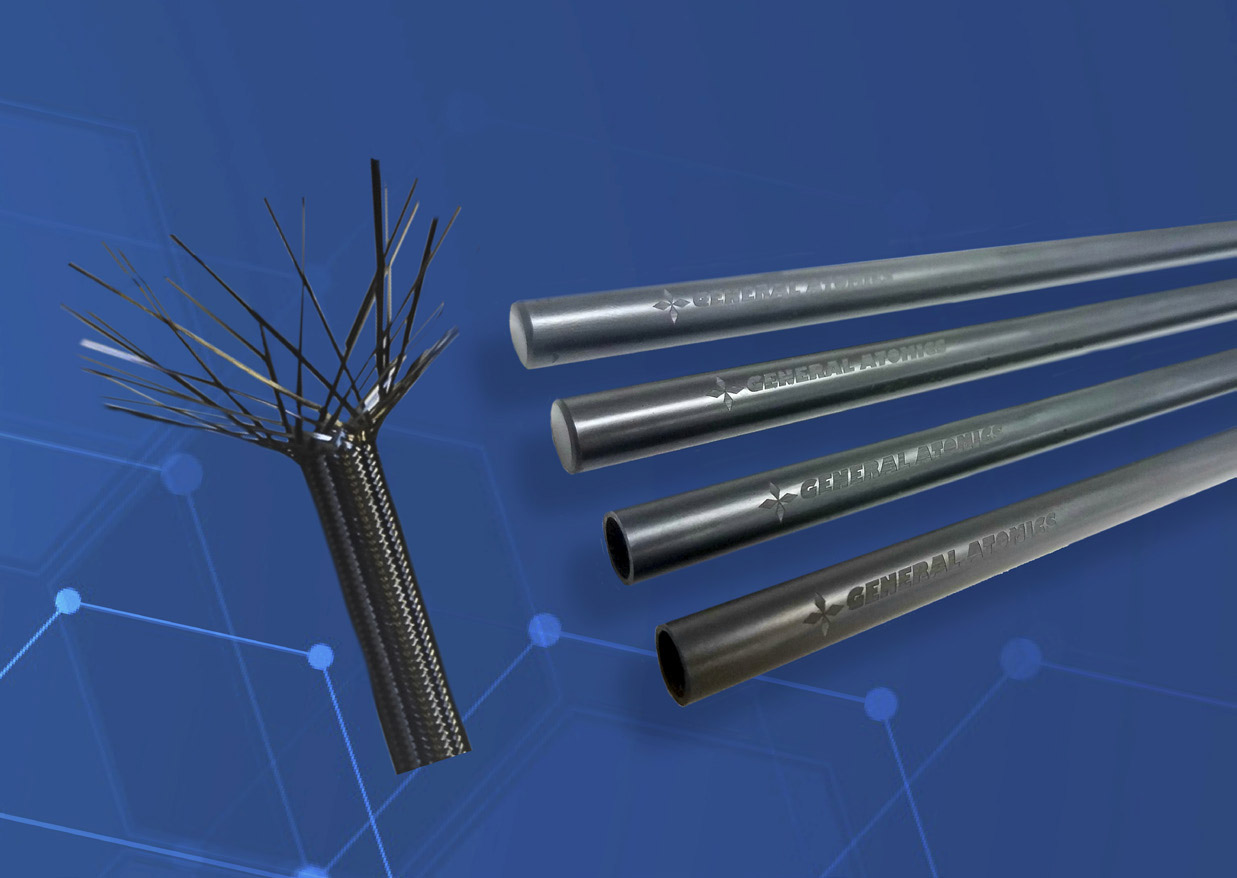

General Atomics SiGA Cladding Accident Tolerant Fuel Rods

General Atomics Electromagnetic Systems (GA-EMS) is charting a path to advance SiGA® silicon carbide (SiC) ceramic matrix composite cladding for nuclear fuel rods to provide enhanced safety, improved operational performance, and economics benefits for the existing Light Water Reactor (LWR) fleet as well as future advanced reactor systems.

From left, INL’s Mark Nefzger, Raymond Clark, and John Jackson and DOE-NE’s and Diana Li pose with a MARVEL component.. (Photo: DOE-NE)

A team from Idaho National Laboratory and the Department of Energy’s Office of Nuclear Energy recently visited Carolina Fabricators Inc. (CFI) in West Columbia, S.C., to launch the fabrication process for the primary coolant system of the MARVEL microreactor. Battelle Energy Alliance, which manages INL, awarded the CFI contract in January.

Judge stands outside INL’s new Sample Preparation Laboratory.

(Photo: INL)

Idaho National Laboratory’s newest facility—the Sample Preparation Laboratory (SPL)—sits across the road from the Hot Fuel Examination Facility (HFEF), which started operating in 1975. SPL will host the first new hot cells at INL’s Materials and Fuels Complex (MFC) in 50 years, giving INL researchers and partners new flexibility to test the structural properties of irradiated materials fresh from the Advanced Test Reactor (ATR) or from a partner’s facility.

Materials meant to withstand extreme conditions in fission or fusion power plants must be tested under similar conditions and pushed past their breaking points so performance and limitations can be understood and improved. Once irradiated, materials samples can be cut down to size in SPL and packaged for testing in other facilities at INL or other national laboratories, commercial labs, or universities. But they can also be subjected to extreme thermal or corrosive conditions and mechanical testing right in SPL, explains Colin Judge, who, as INL’s division director for nuclear materials performance, oversees SPL and other facilities at the MFC.

SPL won’t go “hot” until January 2026, but Judge spoke with NN staff writer Susan Gallier about its capabilities as his team was moving instruments into the new facility.

The IAEA’s Rafael Mariano Grossi (far right) and other IAEA experts joined scientists from China, South Korea, and Switzerland as they collected seawater samples near the Fukushima Daiichi nuclear power plant. (Photo: Dean Calma/IAEA)

International Atomic Energy Agency director general Rafael Mariano Grossi visited Japan’s Fukushima Daiichi site on February 19, where he joined scientists from the Third Institute of Oceanography in China, the Korean Institute for Nuclear Safety in South Korea, and the Spiez Laboratory in Switzerland in collecting seawater samples from a boat near the damaged nuclear power plant.

The Nuclear Regulatory Commission has published its 2024–2025

The Nuclear Regulatory Commission has published its 2024–2025