Two workers walk down an underground passageway at the Waste Isolation Pilot Plant transuranic waste repository in New Mexico. (Photo: DOE)

While still lacking a deep geological repository for the permanent disposal of its commercial used nuclear fuel and high-level radioactive waste, the United States does have regulatory standards for geological nuclear waste disposal.

Having been written nearly 40 years ago, however, those standards are outmoded and lack transparency, according to a special committee of the American Nuclear Society, which has released draft recommendations on revising public health and safety standards for future geological repository projects in the United States.

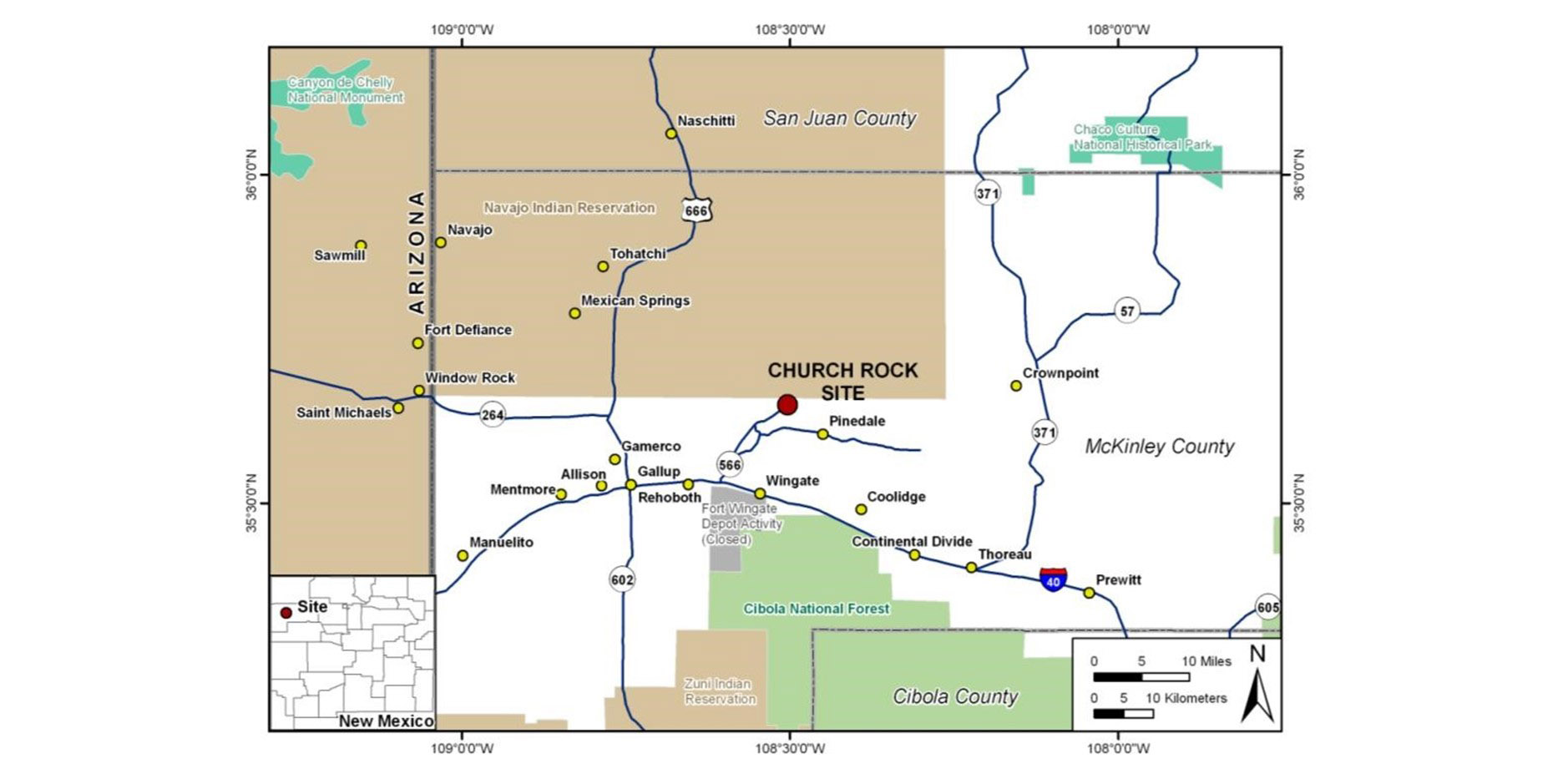

A map of the Church Rock uranium mill site location. (Image: NRC)

The Nuclear Regulatory Commission has approved a plan by United Nuclear Corp. (UNC) to dispose of mine waste from the Northeast Church Rock mine site in New Mexico at the company’s nearby uranium mill and tailings disposal site.

CFS CEO Bob Mumgaard showing Sen. Warren (left) and Secretary Granholm (center) around the SPARC facility. (Photo: CFS)

Commonwealth Fusion Systems (CFS) hosted visiting officials for a tour and ribbon-cutting ceremony to officially open its new headquarters in Devens, Mass., on February 10. Energy secretary Jennifer Granholm, Sen. Elizabeth Warren (D., Mass.), and Sen. Edward Markey (D., Mass.) were among the national, state, and local leaders invited to celebrate what CFS heralded as a “fusion energy campus.”

Two empty waste tanks weighing more than five tons each were transported from outside the Hanford Site’s Effluent Treatment Facility to an on-site landfill. (Photo: DOE)

Two large tanks near the Effluent Treatment Facility (ETF) at the Department of Energy’s Hanford Site in Washington state were removed recently to make way for future wastewater treatment activities at the ETF.

The River Bend nuclear power plant. (Photo: Entergy)

Entergy’s River Bend nuclear power plant started its 22nd scheduled refueling and maintenance outage on February 11. The plant, located in St. Francisville, La., is a 967-MWe General Electric boiling water reactor.

The Zaporizhzhia plant (Image: Energoatom)

As if being stuck in the middle of a combat zone isn’t sufficiently nerve-racking, workers at Ukraine’s Zaporizhzhia nuclear power plant—under Russian occupation since last March—must now concern themselves with having access to enough water to keep the facility safe.

Savannah River’s DWPF has completed the conversion from formic acid to glycolic acid in the waste vitrification process. (Photo: DOE)

The Defense Waste Processing Facility (DWPF) at the Department of Energy’s Savannah River Site (SRS) in South Carolina has resumed operations after a completing a processing improvement that the DOE said will enable safer operations and more efficient vitrification of radioactive waste.

The Waste Isolation Pilot Plant in southeastern New Mexico. (Photo: EPA)

Salado Isolation Mining Contractors (SIMCO), a single-purpose entity comprised of Bechtel National and Los Alamos Technical Associates as a teaming contractor, has assumed responsibility for managing and operating the Waste Isolation Pilot Plant in New Mexico.

Front face of the B Reactor at the Hanford Site. (Photo: DOE)

In remote southeastern Washington you will find the sprawling Hanford Site, which was constructed to produce plutonium for the Manhattan Project. Within this complex is the first plutonium production reactor, the Hanford B Reactor. The DuPont Corporation was responsible for construction and operation of the B Reactor. Due to the urgency of the Manhattan Project, construction was completed in just over a year, and The B Reactor went critical on September 26, 1944. After the needs of the Manhattan Project were satisfied, the reactor was briefly shut down and then restarted to produce plutonium for roughly another 20 years, supporting Cold War efforts. In addition to plutonium production, the B Reactor also pioneered the process to produce tritium for the first-ever thermonuclear test.

The center stack casing staged horizontally at Holtec’s manufacturing division in East Pittsburgh. (Photo: Holtec)

A key component needed for the National Spherical Torus Experiment–Upgrade (NSTX-U), the flagship fusion facility currently under repair at the Department of Energy’s Princeton Plasma Physics Laboratory (PPPL), has been delivered to the lab’s New Jersey campus.

The student social media ambassadors at the IAEA Nuclear Power Ministerial in October 2022 (left to right): Sam Dotson from the University of Illinois, Madison Gitzen from Pennsylvania State University, Peter Hotvedt from the University of Michigan, Jillian Newmyer from Oregon State University, Brienna Johnson from the University of Wisconsin–Madison, and Pearle Lipinski from Ohio State University.

Pearle Lipinski is a nuclear engineering Ph.D. student in Ohio State University’s Department of Mechanical and Aerospace Engineering (MAE). In October 2022, at the International Atomic Energy Agency’s fifth International Ministerial Conference on Nuclear Power in the 21st Century (also known as the Nuclear Power Ministerial, or NPM), she acted as a student social media ambassador, where she was a “huge success in getting the word out,” according to Lei Raymond Cao, director of the OSU nuclear engineering program.

A view of the completed demo cascade. (Photo: Centrus)

Centrus Energy announced February 9 that it has finished assembling a cascade of uranium enrichment centrifuges and most of the associated support systems ahead of its contracted demonstration of high-assay low-enriched uranium (HALEU) production by the end of 2023. When the 16-machine cascade begins operating inside the Piketon, Ohio, American Centrifuge Plant, which has room for 11,520 machines, it will be the first new U.S.-technology based enrichment plant to begin production in 70 years.

The new ANS STEM Academy launched at the end of 2022 encompasses all of the American Nuclear Society’s educational programs. It brings together a state-of-the-art curriculum with nuclear experts and enriches classroom experiences to enable a national expansion of K-12 nuclear science and technology education. The new program strives to serve educators, students, and everyone interested in nuclear science and technology.

The new ANS STEM Academy launched at the end of 2022 encompasses all of the American Nuclear Society’s educational programs. It brings together a state-of-the-art curriculum with nuclear experts and enriches classroom experiences to enable a national expansion of K-12 nuclear science and technology education. The new program strives to serve educators, students, and everyone interested in nuclear science and technology.