See link below to play video.

Kite & Key Media, which produces short videos that provide context on an array of topical issues, has released an online video that sets the record straight on just what nuclear waste is and how its publicly perceived risks don’t match up with reality.

Rendering of the Forsmark geologic repository for spent nuclear fuel in Sweden. Below ground, the repository covers three to four square kilometers at a depth of 500 meters. (Image: SKB)

The government of Sweden announced on January 27 that it has issued a permit to the Swedish Nuclear Fuel and Waste Management Company (SKB) to build a deep geological repository for spent nuclear fuel at Forsmark in the municipality of Östhammar. The government also issued a permit to construct a spent fuel encapsulation plant in Oskarshamn, where the country’s inventory of spent fuel is currently being stored.

This image is described by the Alaska Center for Energy and Power as a conceptual layout of a generic small modular reactor or microreactor. (Image: ACEP)

Alaska Gov. Mike Dunleavy (R.) introduced “An act relating to microreactors” (SB 177) in the Alaska state legislature on February 1 that would modify existing state law on nuclear energy by specifying that microreactors are not subject to certain nuclear reactor siting and permitting regulations in Alaska. The bill defines a microreactor as an advanced nuclear fission reactor that would be capable of generating no more than 50 MWe.

A rendering of the Natrium plant. (Image: TerraPower)

Natrium, a 345-MWe sodium fast reactor with a molten salt energy storage system, was developed by TerraPower and GE Hitachi Nuclear Energy. TerraPower is planning to build the first Natrium demonstration reactor by 2028 with 50-50 cost-shared funding of about $2 billion from the Department of Energy’s Advanced Reactor Demonstration Program. And for the requisite data and testing of reactor components to support that deployment, TerraPower is looking to Japan—a country with decades of experience developing sodium fast reactor designs and testing infrastructure.

February 1, 2022, 12:01PMSponsored ContentJoe Rashid, Senior Associate at Structural Integrity Associates, Inc. The cladding hoop stress distribution at cladding surfaces.

Decades of fuel performance data coupled with advanced analytics and multi-processor computing have enabled the development of ‘novel’ modeling & simulation tools that allow nuclear fuel engineers to predict behavior across the entire fuel cycle. With this new capability nuclear fuel designers and fuel reload managers are better equipped to predict performance and reliability. These tools are fundamental to communicating highfidelity safety margin assessments with the regulator, and, when applied in the early stage of reactor design, can achieve optimum safety system functionality. At the apex of the fuel performance codes development pyramid sit a triad of codes: SI’s Pegasus, DOE’s Bison, and CEA’s Alcyone, which share the commonality of three-dimensional modeling and simulation of nuclear fuel performance. Unique among the capabilities represented by these codes is the ability to bridge the encoded-technology gap between the frontend and the backend of the fuel cycle to eliminate sources of uncertainties in spent fuel safety evaluations. This capability is a distinguishing feature of the Pegasus code.

In a photo from November 2021, the Vogtle plant’s Unit 4 is in the foreground, and Unit 3 is in the center. Units 1 and 2, which entered service in the 1980s, are shown at the top of the photo. (Photo: Georgia Power)

A spokesperson for Georgia Power has confirmed that the projected in-service date for the new Vogtle-3 reactor remains the third quarter of 2022, according to an article published on January 27 on the Power magazine website. The in-service date for Vogtle-4 is targeted for the second quarter of 2023, the spokesperson said.

An SRNS subcontractor technician takes radiological readings of soil near Lower Three Runs, part of a major project to complete the cleanup of a contaminated 25-mile-long stream corridor at SRS. (Photo: DOE) (CLICK TO SEE FULL PHOTO)

Savannah River Nuclear Solutions (SRNS), the Department of Energy’s management and operating contractor for the Savannah River Site in South Carolina, has reached an agreement with the state of South Carolina and federal environmental regulators on the final cleanup of a 25-mile-long stream corridor at the site that was radiologically contaminated as a result of operations during the Cold War.

The corridor consists of Par Pond, nine miles of canals adjacent to the pond, and a stream named Lower Three Runs. The stream begins near the center of the site, just above Par Pond, and winds its way southward across SRS.

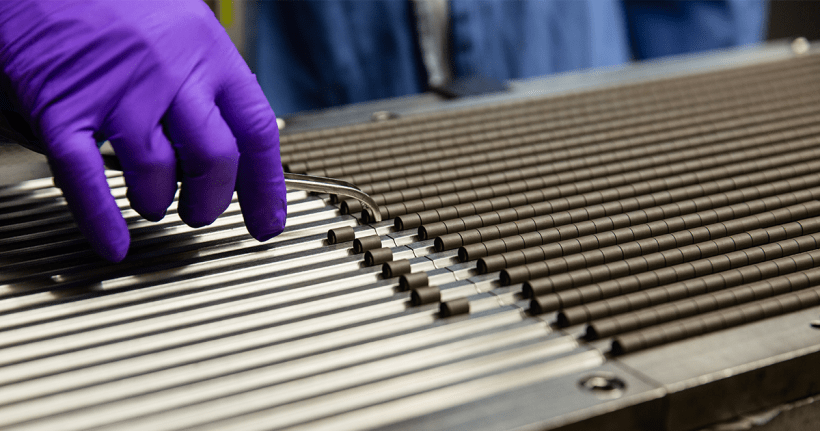

ADOPT fuel pellets developed by Westinghouse through the DOE's Accident Tolerant Fuel Program. (Photo: Westinghouse)

Westinghouse Electric Company and Southern Nuclear have agreed to a plan to install four Westinghouse lead test assemblies in Vogtle-2, a 1,169-MWe pressurized water reactor located in Waynesboro, Ga. Four lead test assemblies containing uranium enriched up to 6 percent U-235 will be loaded in Vogtle-2 in 2023, marking the first time that fuel rods with uranium enriched above 5 percent U-235 are put in use in a U.S. commercial power reactor.

HDI was issued a confirmatory order by the NRC for regulatory violations at Oyster Creek. (Photo: Exelon)

The Nuclear Regulatory Commission has issued a confirmatory order to Holtec Decommissioning International (HDI) following an alternative dispute resolution mediation session regarding security-related violations at the Oyster Creek nuclear power plant in Lacey Township, N.J. A subsidiary of Holtec International, HDI is decommissioning Oyster Creek, which permanently ceased operations in 2018.

A cask of HEU arrives at the H Canyon facility. (Photo: DOE)

The Department of Energy announced yesterday that Secretary of Energy Achievement Awards were presented to a team of Savannah River Site employees for the completion of the multiyear Target Residue Material (TRM) campaign to support global nuclear security goals.

SRS is a 310-square-mile site located in South Carolina. It encompasses parts of Aiken, Barnwell, and Allendale counties and is bordered on the west by the Savannah River and the state of Georgia.

An illustration of the two inertial confinement fusion designs reaching the burning plasma regime, as published in a recent article in Nature. (Image: LLNL)

One of the last remaining milestones in fusion research before attaining ignition and self-sustaining energy production is creating a burning plasma, where the fusion reactions themselves are the primary source of heating in the plasma. A paper published in the journal Nature on January 26 describes recent experiments at Lawrence Livermore National Laboratory’s National Ignition Facility (NIF) that have achieved a burning plasma state.

Workers recently installed manipulator equipment at a full-scale mock-up of areas of the Hanford Site’s Waste Encapsulation and Storage Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced this week that preparations are well underway for the transfer of nearly 2,000 highly radioactive cesium and strontium capsules from the Waste Encapsulation and Storage Facility (WESF) to interim dry storage at the Hanford Site near Richland, Wash.

The cover of the May 1977 issue of Nuclear News (left), an image of the story discussing Carter's decision to cancel the breeder reactor program (center) and the cover of the June 1977 Nuclear News (right).

The ANS Fuel Cycle and Waste Management Division will present a webinar today at noon EST (the recording will be available via the webinar archive to all ANS members) featuring an international panel of experts on nuclear waste reprocessing. The panel will explore the idea of separating certain radionuclides from waste using recycling technology that enables pure materials to be used for other purposes.

Bruce nuclear power plant in Ontario, Canada. (Photo: Bruce Power)

Bruce Power and Isogen, a partnership between Kinectrics and Framatome, have completed the installation of Isogen’s isotope production system (IPS) at Unit 7 of Bruce’s CANDU nuclear power plant in Ontario, Canada, making it the first power reactor in the world with installed capability to produce lutetium-177.