The 40-year effort to make research reactors safer and more secure has led to the conversion of 71 reactors worldwide from HEU fuel to LEU.

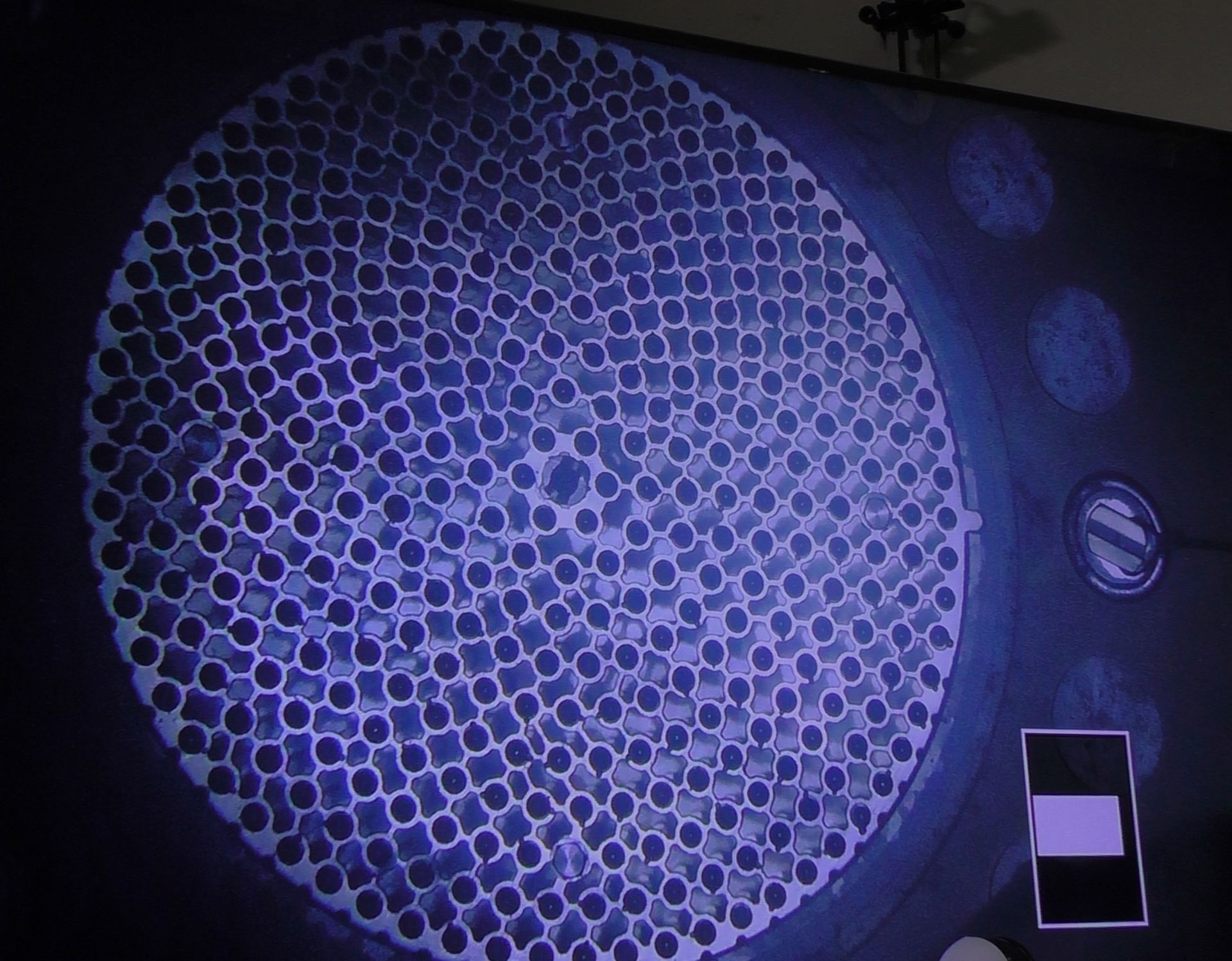

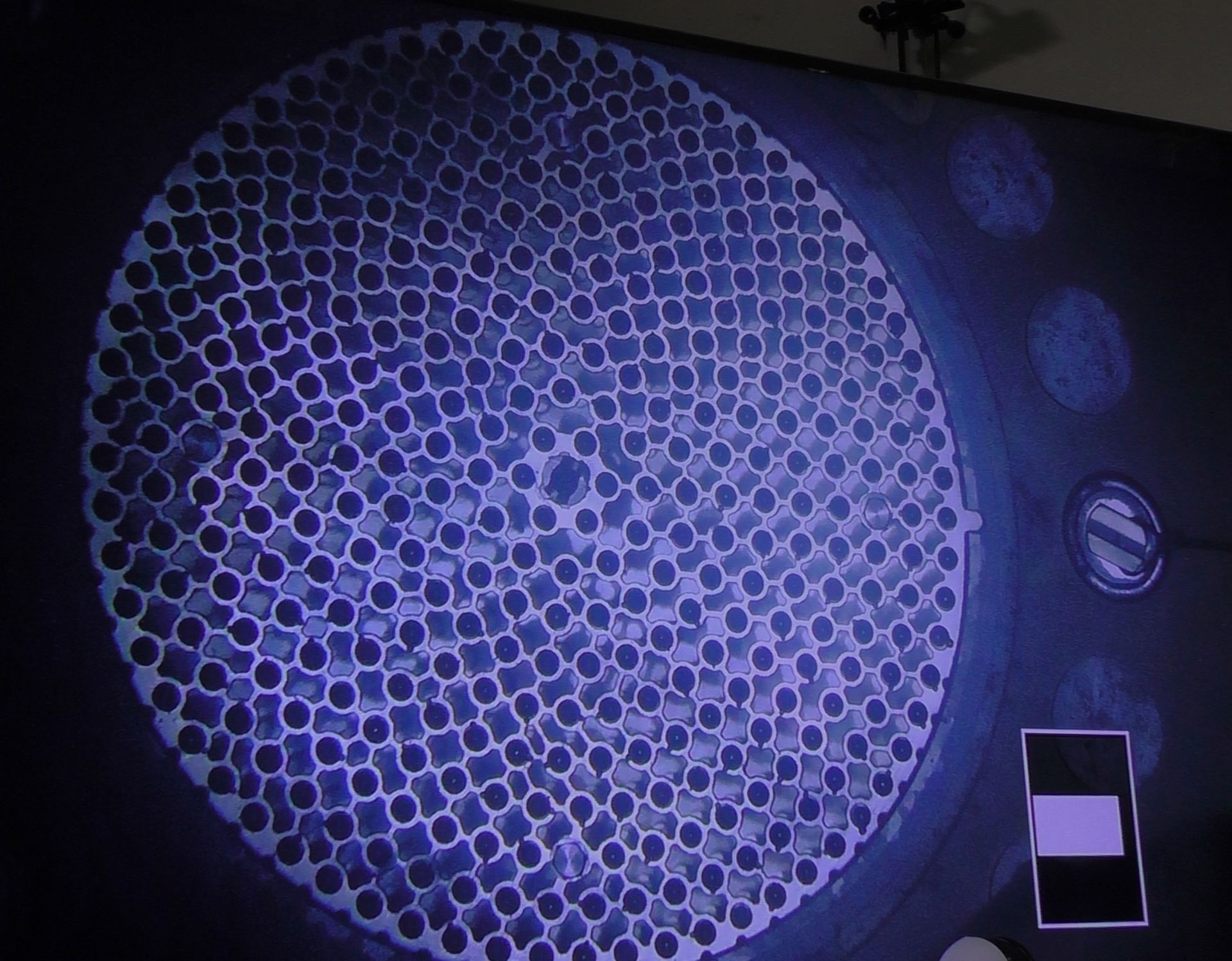

The Ghana Research Reactor-1, located in Accra, Ghana, was converted from HEU fuel to LEU in 2017. Photo: Argonne National Laboratory

In late 2018, Nigeria’s sole operating nuclear research reactor, NIRR-1, switched to a safer uranium fuel. Coming just 18 months on the heels of a celebrated conversion in Ghana, the NIRR-1 reboot passed without much fanfare. However, the switch marked an important global milestone: NIRR-1 was the last of Africa’s 11 operating research reactors to run on high-enriched uranium fuel.

The 40-year effort to make research reactors safer and more secure by replacing HEU fuel with low-enriched uranium is marked by a succession of quiet but immeasurably significant milestones like these. Before Africa, a team of engineers from many organizations, including the U.S. Department of Energy’s Argonne National Laboratory, concluded its conversion work in South America and Australia. Worldwide, 71 reactors in nearly 40 countries have undergone conversions to LEU, defined as less than 20 percent uranium-235. Another 31 research reactors have been permanently shut down.

CORTEX aims to enable the early detection, localization, and characterization of anomalies in nuclear reactors while they are operating.

We often define noise as an unwanted disturbance, especially acoustic in nature. Neutron noise, by contrast, is a direct measure of the dynamics of a nuclear core. It can be used for core monitoring without disturbing plant operation and by using the existing core instrumentation. The European CORTEX project aims to develop an innovative core monitoring technique using neutron noise, while capitalizing on the latest developments in neutronic modeling, signal processing, and artificial intelligence.

Digital engineering, which uses advanced technologies to capture data and optimize design in a digital environment, is being applied for the first time to a DOE nuclear project and has already realized substantial benefits.

With a new generation of nuclear reactors in the works, Idaho National Laboratory has embraced digital engineering (DE) as a means of achieving the same efficiencies that companies in the private sector have been able to realize in everything from concert halls to aircraft engines.

DE—using advanced technologies to capture data and craft design in a digitized environment—has been evolving since the 1990s. For Mortenson Construction, a worldwide construction firm, using virtual design and construction resulted in a cumulative 600 days saved over 416 projects and a 25 percent increase in productivity. By building digital twins for assets, systems, and processes, DE has avoided more than $1.05 billion in customer, production, and mechanical losses.

Leaders at INL recognized in 2018 that DE could be useful in the design and construction of new commercial and test reactors. Managing construction costs, timing, and performance will be essential to maintain U.S. competitiveness.

A new report from the American Institute of Physics declares the physical sciences to be at a “tipping point” between a “perilous” future and a “vibrant” one as a result of the coronavirus pandemic. The 28-page report,

A new report from the American Institute of Physics declares the physical sciences to be at a “tipping point” between a “perilous” future and a “vibrant” one as a result of the coronavirus pandemic. The 28-page report,

A new report from the Paris-based OECD Nuclear Energy Agency declares that nuclear power is needed for countries to meet their Paris Agreement decarbonization and energy security policy goals, but that governmental support for a rapid reduction in the cost of new nuclear capacity through the creation of certain policy frameworks is likely necessary.

A new report from the Paris-based OECD Nuclear Energy Agency declares that nuclear power is needed for countries to meet their Paris Agreement decarbonization and energy security policy goals, but that governmental support for a rapid reduction in the cost of new nuclear capacity through the creation of certain policy frameworks is likely necessary.