The DOE’s Transformational Challenge Reactor program is harnessing recent advances in manufacturing, materials, and computational sciences to rapidly build and operate an advanced reactor core.

The TCR program is leveraging an agile approach—one that is centered around continuously informing the process—to accelerate deployment timelines and introduce performance improvements. Image: Adam Malin, ORNL

Soon after Enrico Fermi’s Chicago Pile-1 went critical for a brief duration in December 1942, the construction of the first continuously operating reactor, the X-10 Graphite Reactor, was initiated in February 1943 at Clinton Engineer Works in Oak Ridge, Tenn. On November 4 of that year, a mere nine months after the start of construction, the reactor began operation. This marked the onset of what Alvin M. Weinberg referred to as “the first nuclear era,” during which many reactors of various designs and operating parameters were built and demonstrated across the United States. Forty years ago, the Fast Flux Test Facility was the last U.S. non-light-water reactor to reach criticality, and it has since been decommissioned.

The partial collapse of PUREX Tunnel 1 in 2017 prompted a review of Hanford’s maintenance of the site’s unused, contaminated buildings.

A report released to the public on February 20 by the Government Accountability Office concluded that maintenance inspections at several contaminated excess facilities at the Department of Energy’s Hanford Site, near Richland, Wash., have not been comprehensive and that there are areas of some facilities that personnel infrequently or never enter, either physically or by remote means, to conduct inspections. The GAO reviewed surveillance and maintenance (S&M) requirements and activities at 18 of Hanford’s approximately 800 excess facilities that require cleanup and found that improvements to the site’s S&M program are needed.

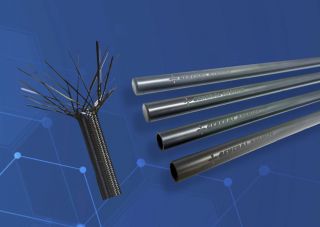

BWXT is using advances in manufacturing and fuel to power exciting technology

The United States is pursuing the objective to land humans more than 100 million miles away on Mars, and nuclear power has the potential to be a key technology in getting to the Red Planet and providing power while there. Specifically, nuclear thermal propulsion (NTP) is a promising approach that could enable astronauts to travel from Earth’s orbit to Mars and back in a fraction of the time, and with greater safety, than is available with other options.

ASME Best Oral Presentation/Paper Waste Management 2019

March 10, 2020, 9:02AMRadwaste SolutionsThao Do, Jiju Joseph, Giles Whitaker, Barb Noye, Vasile Bostan, Don Jarron, and J. Clara Wren As nuclear power plants age and retire from service, many countries face significant challenges concerning the safe long-term storage and disposal of large volumes of low- and intermediate-level radioactive wastes (L&ILW). In Canada, Ontario Power Generation (OPG) is currently in the process of obtaining regulatory approval for a deep geological repository (L&ILW DGR) for such wastes from decommissioning and refurbishment of its heavy water reactors. OPG is exploring innovative methods and technologies to improve safety and reduce the processing, transportation, and disposal costs of these wastes. The volumes of metallic waste are of particular concern, because when metal corrodes it produces hydrogen that could lead to pressure buildup in the L&ILW DGR.

ANS Best Oral Presentation/Paper Waste Management 2019

March 10, 2020, 8:42AMRadwaste SolutionsLaura Merlo-Sosa, Hugh Boniface, Richard Prokopowicz, and Sam Suppiah Heavy water is used both for moderating nuclear fission and transporting heat in CANDU reactors. As a result of heavy water use in these systems, tritium is produced in small quantities from thermal neutron activation of deuterium. The presence of tritium in the heavy water contributes to the radiation dose of the reactor staff and radioactive emission from the reactor facility. Tritium dose is usually controlled through design and operating procedures that minimize leaks and limit exposure to the tritiated water. Many of the CANDU operators have also reduced the operational tritium concentration through detritiation of the heavy water from the reactor. Detritiation is carried out in a centralized facility, such as the Tritium Removal Facility in Darlington, which provides this service to Ontario’s nuclear reactor fleet. Detritiation reduces both tritium emission and dose to workers and the public from reactor operation.