Next Generation MG Control Power Cabinets Installed

Westinghouse Parts Business (WPB) is proud of the first next generation Motor Generator (MG) Set System fully operational at Palo Verde Generating Station. The team completed a first-of-a-kind (FOAK) implementation and installation at the power plant operated by Arizona Public Service (APS), including the next generation MG Control Power Cabinets and new MG Sets. Additionally, Westinghouse installed the new ARCH (Advanced Rod Control Hybrid) system. These systems were installed in a single outage providing additional synergies and cost savings to operations.

A message from Nucleation Capital

Concept image by Adrian Smith + Gordon Gill Architecture LLP.

Nucleation Capital is a new venture fund focused on investing in next-generation nuclear energy and deep decarbonization. We are pleased to introduce ourselves to the broader nuclear community under the ANS theme “Invested in Nuclear.” Investing is always a forward-looking endeavor and, from what seemed to be an uncertain future, we’re delighted to see the industry anticipating substantial new growth and working to support it.

Bolstering this new outlook are important trends that are worth highlighting. We’re all seeing amazing shifts in how nuclear power is discussed. In the last few years, Nuclear has garnered surprise support from Democratic governors seeking to protect existing plants and Republican governors repealing old nuclear bans and vying to get next-gen plants sited in their states. In key pieces of federal climate legislation, nuclear has seen equal treatment under ITCs and PTCs and billions allocated to help save older plants and accelerate commercialization of new plants.

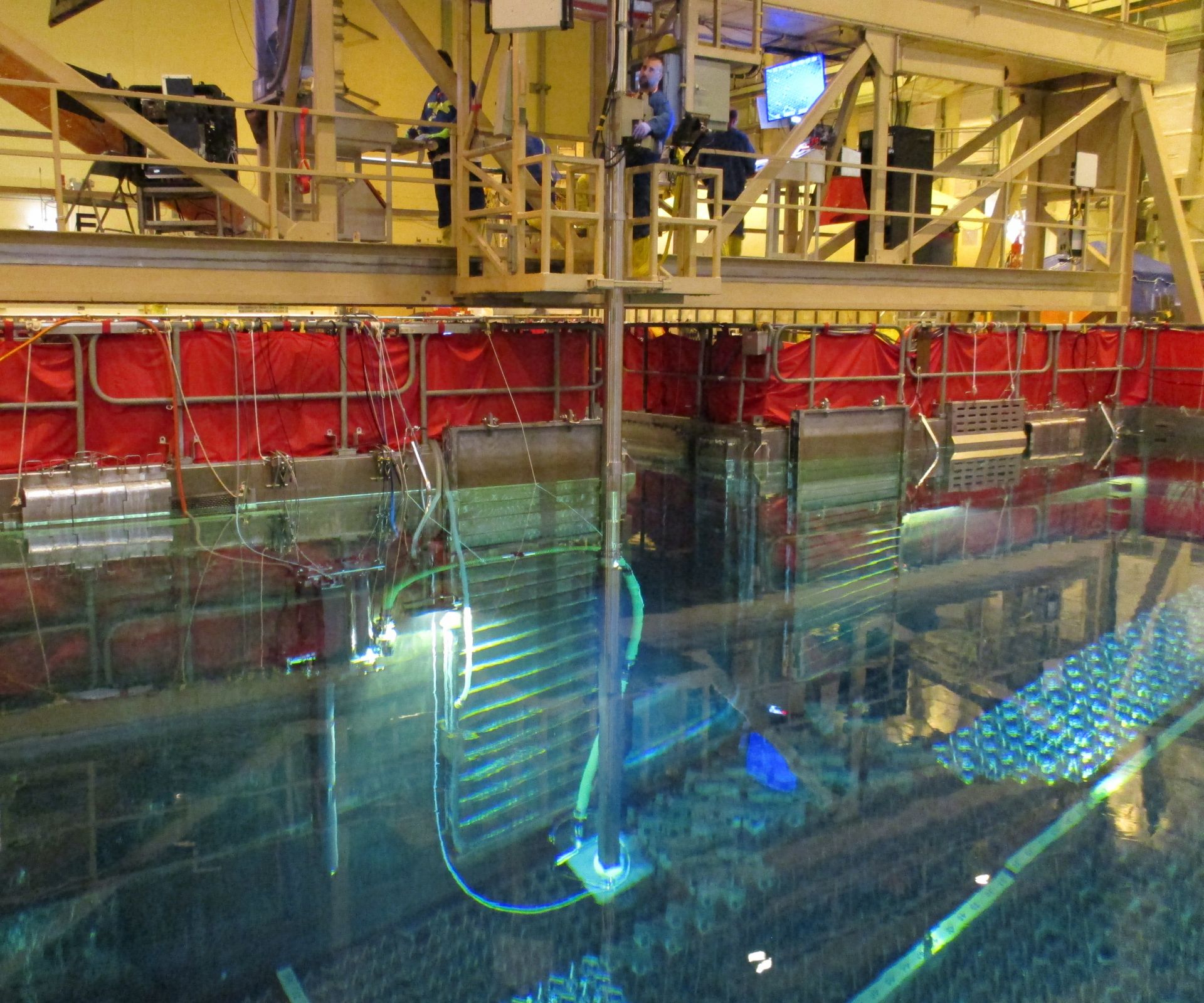

BWR spent fuel pool dual SCF system with shields.

The return of low natural gas prices combined with the advent of high efficiency renewables has placed more pressure on nuclear power plant operators to reduce their operational and maintenance costs and to increase plant availability while continually meeting the increasing number of safety and regulatory requirements. Outage management is a key factor for good, safe, and economic nuclear power plant performance; it involves detailed planning and preparation as well as the application of proven advanced technologies for completing task activities. Outage tasks frequently require the use of pure, high clarity water. Traditional filtration technologies used for maintaining clarity have long been the bane of many nuclear plant operators. Poor water quality in the fuel pool and reactor cavity can cause high radiation exposure, and high turbidity can lead to the slow-down or complete stoppage of underwater work activities.

Goodway Technologies GDS-100 Scale Removal System

Power generation has many factors and key indicators to identify the “health” of a plant. Some macro-level indicators are vital to help identify challenges before they become problems; others are less sensitive yet just as important. Micro indicators such as condenser return temps or changes in pump pressures can be critical indicators of a problem that few understand, yet which results in enormous loss of efficiency. That problem is deposits on critical system tubing and piping caused by calcium carbonate or other mineral buildups. The bottom line? Scaling is a significant issue in power plants that can considerably impact efficiency and profitability.

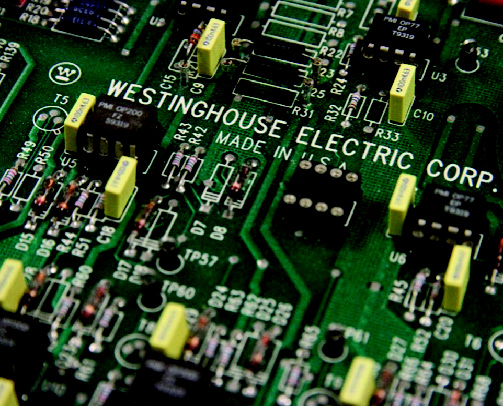

Westinghouse employee completing visual inspection of I&C part

Obsolescence and the ability to obtain qualified replacement and spare parts are primary concerns in the nuclear industry. In fact, approximately 35% of installed equipment is obsolete.

Westinghouse Parts Business (WPB) has over 50 years of experience replacing and upgrading systems for operating nuclear power plants with access to original design information as the original equipment manufacturer (OEM).

WPB provides innovative, cost-efficient solutions for Westinghouse and non-Westinghouse systems in order to increase reliability of I&C systems, including enhanced replacement components, repair and refurbishment services. Recently, WPB has supported numerous customers in obsolescence and Reverse Engineering (RE) services.

February 1, 2022, 12:01PMSponsored ContentJoe Rashid, Senior Associate at Structural Integrity Associates, Inc. The cladding hoop stress distribution at cladding surfaces.

Decades of fuel performance data coupled with advanced analytics and multi-processor computing have enabled the development of ‘novel’ modeling & simulation tools that allow nuclear fuel engineers to predict behavior across the entire fuel cycle. With this new capability nuclear fuel designers and fuel reload managers are better equipped to predict performance and reliability. These tools are fundamental to communicating highfidelity safety margin assessments with the regulator, and, when applied in the early stage of reactor design, can achieve optimum safety system functionality. At the apex of the fuel performance codes development pyramid sit a triad of codes: SI’s Pegasus, DOE’s Bison, and CEA’s Alcyone, which share the commonality of three-dimensional modeling and simulation of nuclear fuel performance. Unique among the capabilities represented by these codes is the ability to bridge the encoded-technology gap between the frontend and the backend of the fuel cycle to eliminate sources of uncertainties in spent fuel safety evaluations. This capability is a distinguishing feature of the Pegasus code.

EnergySolutions announced the stock transfer of Kewaunee from Dominion Energy in May 2021 and is in the process of approval by the U.S. Nuclear Regulatory Commission and Public Service Commission of Wisconsin.

Contrary to what some believe, the nuclear industry, far from fading into the past, is experiencing an ongoing evolution. New generations of nuclear power technologies move closer to reality, while traditional nuclear generators are reaching retirement and entering decommissioning. As research on Small Modular Reactors (SMR) advances, prototype production is in full swing with the potential for SMRs to eventually replace the current fleet. And while technology advances, so do markets seeking to deal with the challenge of climate change in the face of the retirement of the currently operating nuclear power plants in the U.S. In an exceptional recent win for nuclear power, the Illinois legislature approved $700 million in subsidies for the Byron and Dresden nuclear stations over the next five years. It remains to be seen if this will be an isolated move in today’s nuclear plant lifecycle.

An innovative, rapidly deployable battery power supply system that enhances operator flexibility, improves stations’ probabilistic risk assessment profile, and augments FLEX response.

September 1, 2021, 11:55AMSponsored ContentBenjamin P. Youman, BlackStarTech Strategic Implementation Director Quad Cities Generating Station. Image: Exelon.

BlackStarTech® Innovation Group asked one simple question:

How do we further improve the response times of our FLEX strategies?

That question led to a second question:

Can we add defense in depth to U.S. FLEX response, enhance safety margins, and strategically provide critical power rapidly and reliably in under 30 minutes for up to 30 days?

The response and resultant innovative journey led to the development of a rapidly deployable and portable battery-powered energy delivery system transforming how the nuclear industry can provide critical DC and AC power to the most essential components and control systems. The BlackStarTech methodology utilizes compact and portable power supplies to further enhance essential equipment availability, as well as providing defense in depth to FLEX and B.5.b response. The portable battery power technology provides an alternative means of electrical power delivery solutions, expanding operator flexibility and optimizing station risk reduction strategies.

ORNL associate laboratory director Kathy McCarthy at the prototype which led to the Material Plasma Exposure eXperiment (MPEX), a device that will support fusion materials research. Photo: ORNL

Oak Ridge National Laboratory has a long record of advancing fusion and fission science and technology. Today, the lab is focused more than ever on taking advantage of that spectrum of nuclear experience to accelerate a viable path to fusion energy and to speed efficient deployment of advanced nuclear technologies to today’s power plants and future fission systems.

Guided waves and robots advancing inspection of areas with limited access

The Hanford Site in Washington state stores millions of gallons of high-level radioactive waste in 28 double-shell tanks. The tanks are buried underground to enhance radiation shielding. The space between the primary tank and the steel liner can be used to allow inspection of the inaccessible regions of these vessels.

Nuclear power plant containment vessels have large, inaccessible regions that cannot be inspected by conventional techniques. Inaccessible regions often are encased in concrete, soil or sand, or hidden behind equipment attached to a wall. Similar constraints affect the inspection of double-shell tanks designed to store nuclear waste, illustrated in Figure 1, that have an inaccessible region at the tank bottom where the primary shell is supported by the secondary shell. Present methods to monitor the integrity of these vessels primarily rely on partial inspections of accessible areas or estimation of corrosion rates; however, these approaches cannot account for nonuniform localized corrosion or cracking.