How High-Velocity Thermal Spray Enhances Efficiency, Safety, and Lifecycle Performance

HVTS Application

As many Pressurized Water Reactors (PWRs) approach or exceed 40 years of operation, maintaining asset integrity under aging infrastructure, tight outage schedules, and strict ALARA (As Low As Reasonably Achievable) mandates is a real challenge.

Discover Why EXOSENS Detectors are Essential for Advanced Reactor Monitoring in Extreme Conditions

As the global energy landscape shifts towards safer, smaller, and more flexible nuclear power, Small Modular Reactors (SMRs) and Gen. IV* technologies are at the forefront of innovation. These advanced designs pose new challenges in size, efficiency, and operating environment that traditional instrumentation and control solutions aren’t always designed to handle.

Schulz Electric’s nuclear group specializes in nuclear motor repair. We offer a variety of nuclear services including environmentally qualified form and random wound insulation, contaminated electric motor repair with RCP electric motor overhaul and rewind, safety-related repairs, electric motor testing capabilities, high-quality, costeffective solutions for MOV dilemmas, all from our nuclear motor repair facility and in-house decontamination facility.

The Primary Challenge

Schulz Electric™ was contacted by a nuclear power plant in the New England region that serves a community of over 2 million homes. After five years of service, a 1500 HP, 4 kV, 24-pole circulating water pump motor (measuring approximately 7’ wide, 8’ tall, and weighing several tons) needed refurbishing while the plant was still online. To add to their concern, the power plant is located close to the ocean. The aging motor was not only approaching the end of its serviceable life, but was highly susceptible to moisture intrusion and the salt-laden air, which can build up in air passages within the motor. These environmental conditions can lead to elevated operating temperatures and corrosion developing on the rotor, stator, and shaft components. These factors combined, placed the plant at an increased risk of downtime that could have potentially led to a significant loss of revenue if they were forced into a shutdown event.

Figure 1. inDRUM Demonstration facility at Studsvik for simulated waste (left) and a drum being loaded into the container treatment unit (right)

Studsvik AB has completed construction of the new inDRUM Demonstration Facility outside of Nykoping, Sweden. We can now demonstrate how the inDRUM technology will process a wide range of problematic and legacy wastes through the removal of all liquids, organics and other materials, resulting in a stable and reduced volume product that can be disposed of in a suitable repository.

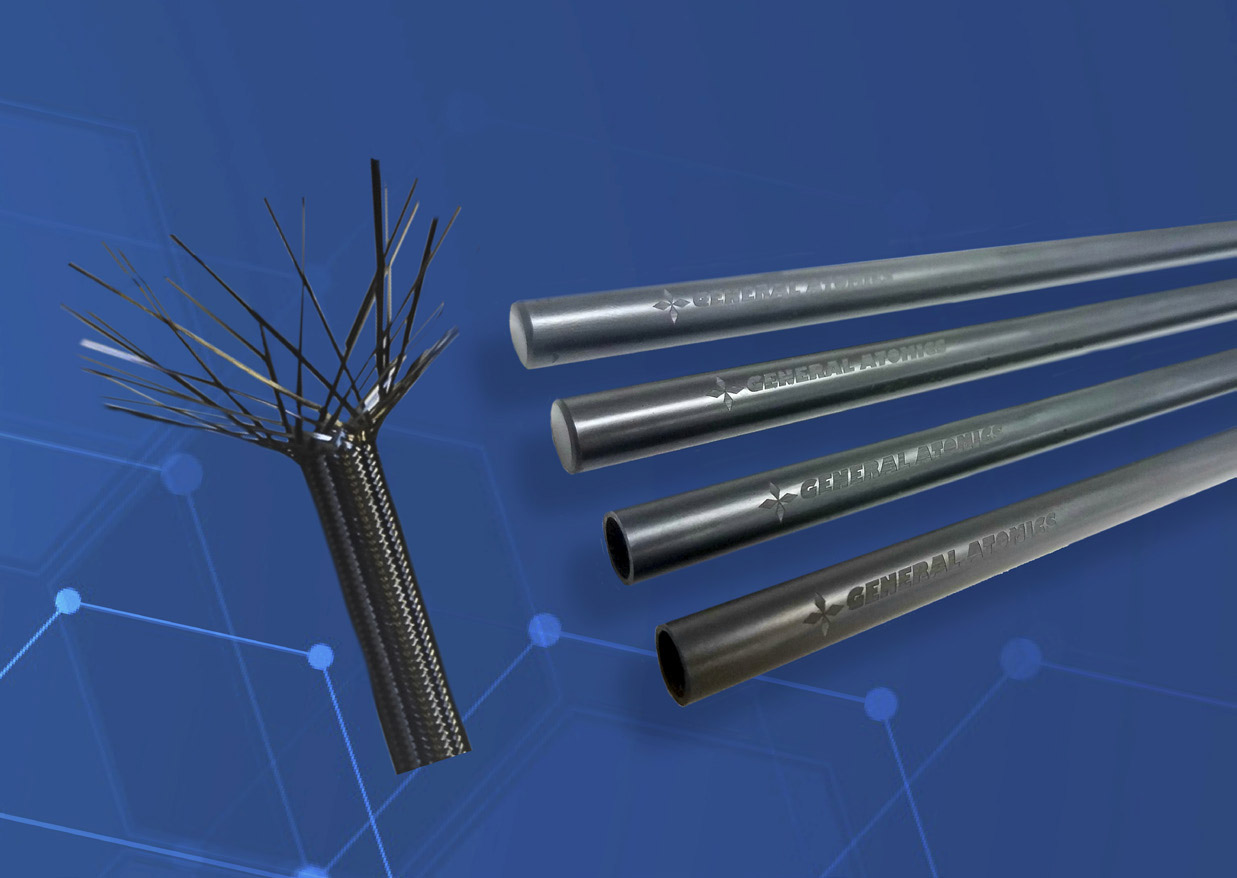

General Atomics SiGA Cladding Accident Tolerant Fuel Rods

General Atomics Electromagnetic Systems (GA-EMS) is charting a path to advance SiGA® silicon carbide (SiC) ceramic matrix composite cladding for nuclear fuel rods to provide enhanced safety, improved operational performance, and economics benefits for the existing Light Water Reactor (LWR) fleet as well as future advanced reactor systems.