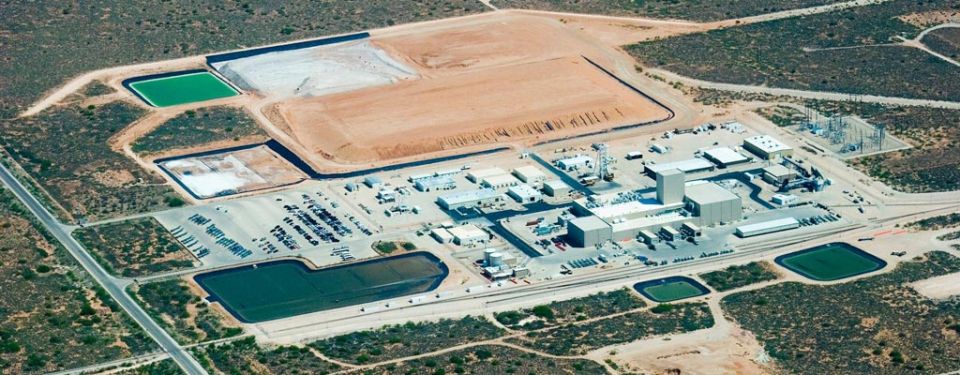

The Waste Isolation Pilot Plant, near Carlsbad, N.M. (Photo: DOE)

The Department of Energy’s Office of Environmental Management has issued a request for qualifications for interested parties and prospective offerors looking to enter into a realty agreement for carbon-pollution-free electricity (CFE) projects at the department’s Waste Isolation Pilot Plant site in southeastern New Mexico.

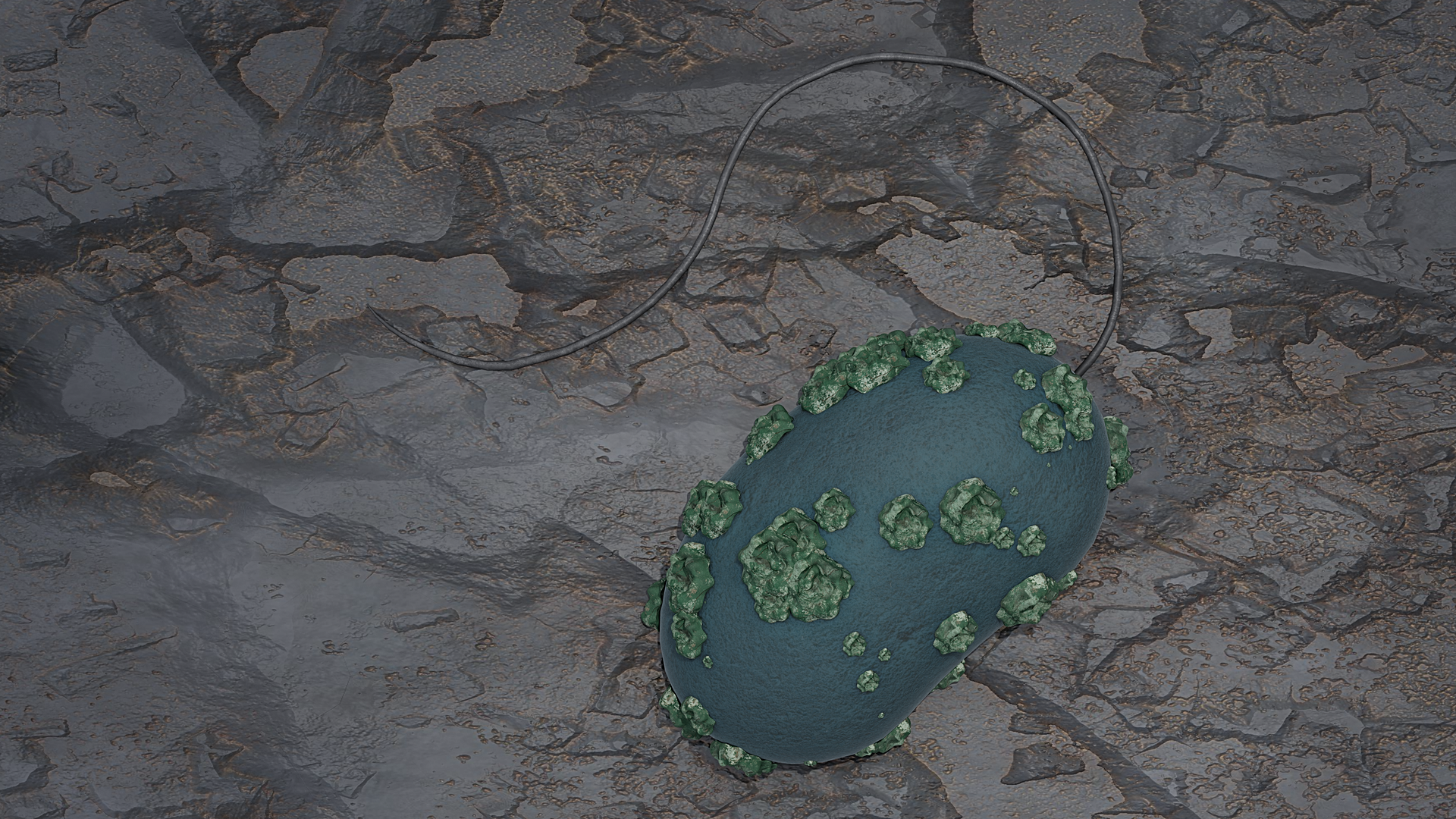

An artistic representation of a Desulfosporosinus cell with immobilized uranium on the surface. (Image: B. Schröder/HZDR)

Researchers at the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) research laboratory in Germany have investigated a microorganism capable of transforming water-soluble hexavalent uranium [U(VI)] to the less-mobile tetravalent uranium [U(IV)]. The researchers found that the sulfate-reducing bacterium Desulfosporosinus hippei, a relative of naturally occurring microorganisms present in clay rock and bentonite, showed a relatively fast removal of uranium from clay pore water.

Is a new generic repository standard on the horizon?

Funding in President Biden’s proposed fiscal year 2025 budget may signal movement toward the promulgation of a new generic Environmental Protection Agency standard for high-level nuclear waste repositories in the United States.

Vit Plant crews begin adding frit into Hanford’s second melter. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management recently announced that crews at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, recently brought the second of two 300-ton melters up to the operating temperature of 2,100°F.

The DOE’s Argonne National Laboratory in Lemont, Ill. (Photo: DOE)

Researchers at the Department of Energy’s Argonne National Laboratory are developing and deploying ARG-US (from the Greek Argus, meaning “Watchful Guardian”) remote monitoring systems technologies to enhance the safety, security, and safeguards (3S) of packages of nuclear and other radioactive material during storage, transportation, and disposal.

As part of its DUF6 conversion program, the DOE is shipping converted depleted uranium oxide to WCS for disposal.

The first major shipment of depleted uranium oxide for disposal departs the DOE’s Paducah Site in Kentucky in early 2023 for disposal at the WCS facility in Texas.

Last year in late August, 120 storage cylinders of depleted uranium oxide (DUOx) safely arrived by rail in West Texas, having been shipped from the Department of Energy’s Portsmouth Site in Ohio. It was the first such shipment of the stable crystalline powder from the Portsmouth Site and was another milestone in the DOE Office of Environmental Management’s (EM) efforts to ship DUOx for off-site disposal.

SRMC’s Dave Olson (left) presents a $10,000 check to Voorhees University president Ronnie Hopkins. (Photo: SRMS)

Savannah River Mission Completion (SRMC), the liquid waste contractor at the Department of Energy’s Savannah River Site, recently presented a $10,000 check to Voorhees University to fund science, technology, engineering, and math (STEM) scholarships.

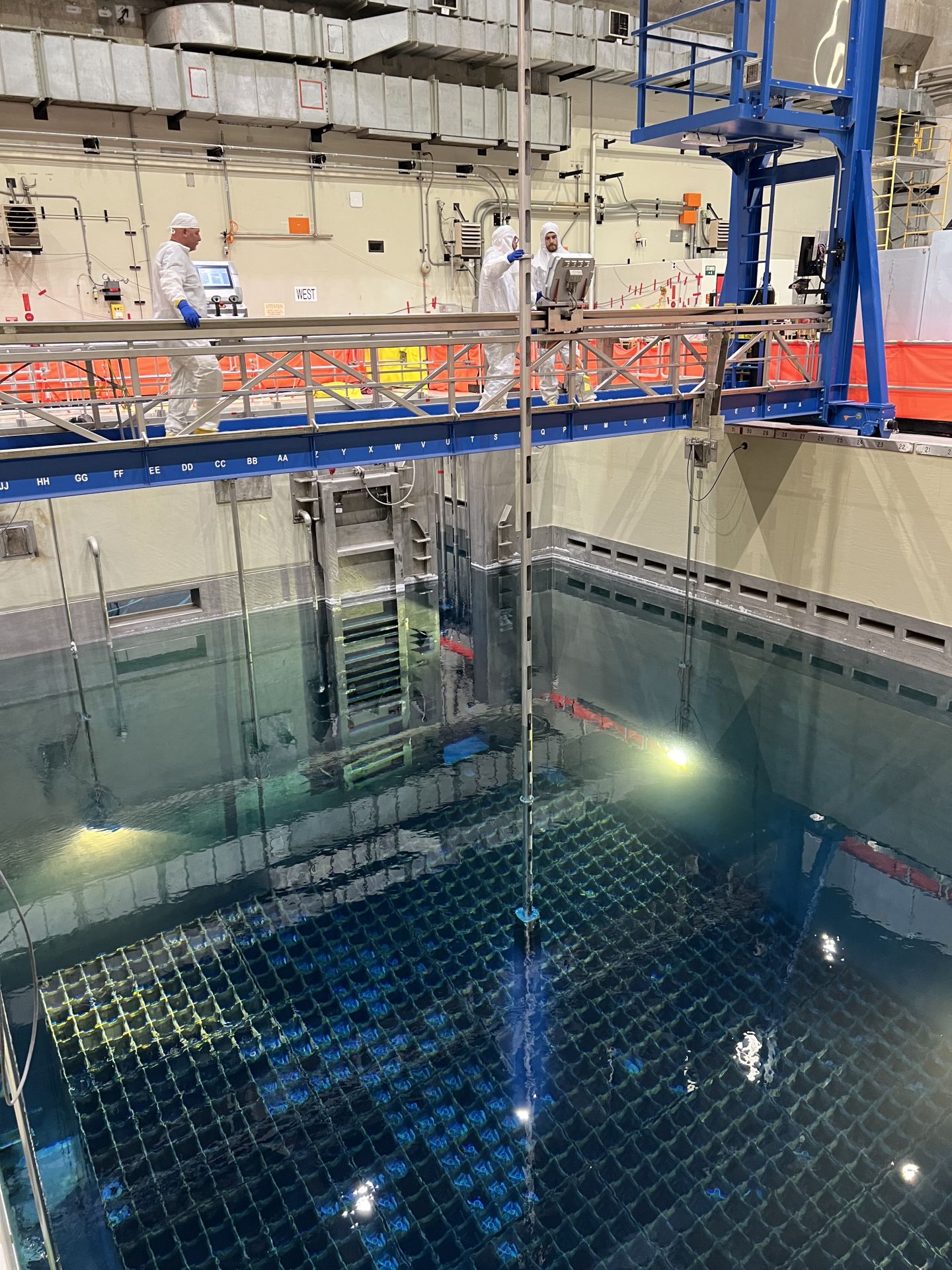

Upgrades are under way at the Hanford Site's 222-S Laboratory, including replacing the Cold War-era windows in the labs hot cells. Photo: DOE)

A screen shot of a video marking the 25th anniversary of operations at the WIPP disposal facility. (Image: DOE)

The Department of Energy’s Office of Environmental Management celebrated a major milestone for the Waste Isolation Pilot Plant last week, marking the 25th anniversary of the receipt of the first waste shipment at the disposal facility in New Mexico’s Chihuahuan Desert.

From left, Erik Olds, OREM deputy manager; Jay Mullis, OREM manager; Brandon Bishop, NABTU secretary-treasurer; Sean McGarvey, NABTU president; Ken Rueter, UCOR president and CEO; William “Ike” White, DOE-EM senior advisor; and Jeff Avery, DOE-EM principal deputy assistant secretary.

The Department of Energy’s Office of Environmental Management announced the signing of a project labor agreement (PLA) between Oak Ridge Office of Environmental Management (OREM) contractor UCOR and North America’s Building Trades Unions (NABTU). The agreement, which allows for flexibility in wage increases and other incentives, is expected to help recruit and retain skilled construction trade workers at the DOE site in Tennessee.

SRS successfully made the first transfer of decontaminated salt solution directly from one waste processing facility to the other, bypassing a hold tank previously used in the transfer process. (Photo: DOE)

The Department of Energy Office of Environmental Management’s liquid waste contractor at the Savannah River Site this month marked the first direct transfer of decontaminated waste from the Salt Waste Processing Facility (SWPF) to the Saltstone Production Facility (SPF). This is a new step in optimizing waste processing, according to the DOE.

The site of the Maine Yankee nuclear power plant, which was decommissioned in 2005. As with its sister plants Yankee Rowe and Connecticut Yankee, all that remains of the site is the plant ISFSI. Without a national waste management solution, spent fuel will continue to sit at sites such as these. (Photo: Maine Yankee Atomic Power Company)

After decades of false starts, U-turns, and stasis, the United States has arrived at a de facto solution for its high-level nuclear waste: Leave it in storage where it was produced, no matter how many tens of billions of dollars it costs, what impediments it raises for nuclear expansion, or what burdens it creates for the reuse of old reactor sites.

Dumb as it sounds, this is keeping all the major players happy. And it avoids alternative pathways, each of which has problems.

Waste drums at the Winfrith site's treated radwaste storage facility. (Photo: NWS)

More than 1,000 drums of low-level radioactive waste in the United Kingdom have been safely disposed of earlier than expected. The project was completed through the collaborative work of Nuclear Waste Services (NWS), Nuclear Restoration Services (NRS), and Nuclear Transport Solutions (NTS).

Electrician Joshua Dickinson (left) leads a group of craft employees through the “School of Hazards” course. (Photo: DOE)

A new program at the Savannah River Site is educating workers on everyday workplace hazards through a new hands-on, peer-led mobile field course.