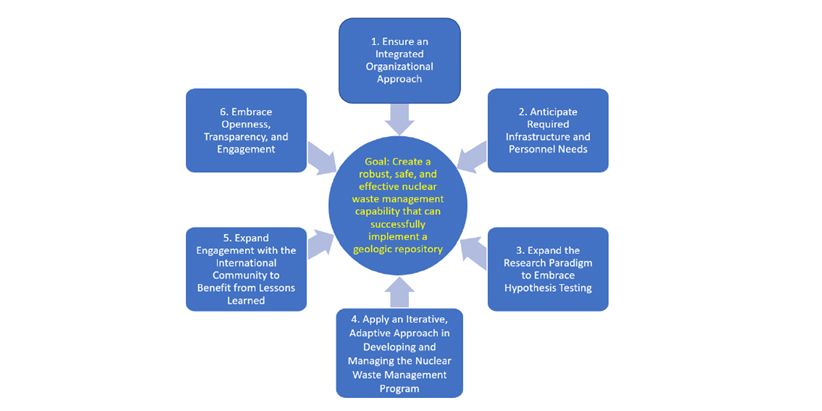

The NWTRB’s six overarching recommendations for the DOE’s nuclear waste management program.

The B Complex area tank farm at the DOE’s Hanford Site in Washington. Photo: DOE

The Department of Energy announced that it has determined that an underground single-shell waste tank at its Hanford Site near Richland, Wash., is likely leaking into the soil beneath the tank. The DOE said that the leaking tank poses no increased health or safety risk to the Hanford workforce or the public.

In 2020, the DOE announced real progress made in the management of liquid radioactive waste at its sites at Savannah River, Idaho, and Hanford.

Plant startup employees work in the process cell area of the Low-Activity Waste Facility at Hanford’s Waste Treatment and Immobilization Plant.

During the annual National Cleanup Workshop, held virtually in September of last year due to the COVID-19 health crisis, William “Ike” White, senior advisor to the under secretary for science in the Department of Energy’s Office of Environmental Management, said that despite the pandemic, 2020 was an inflection year for the DOE and his office.

SRNS subcontractors Donald Miles and Richard Mooney drill for soil samples as part of a project to immobilize I-129 in the groundwater and soil at the Savannah River Site. Photo: DOE/SRNS

A silver chloride–based cleanup technology is expected to reduce radioactive iodine-129 contamination found in soil and groundwater near the center of the Department of Energy’s Savannah River Site in South Carolina to levels well below regulatory limits. The I-129 was created during the production of plutonium and tritium at the site throughout the Cold War era.

Participating in the ceremony to hand over the ISF-2 operating license are (from left) Valery Seyda, acting director general of the Chernobyl nuclear power plant; Ukrainian President Volodymyr Zelensky; and SNRIU Chairman Grigoriy Plachkov.

Ukraine’s State Nuclear Regulatory Inspectorate (SNRIU) has authorized the operation of Chernobyl’s Interim Storage Facility (ISF-2), allowing spent nuclear fuel from the plant’s three undamaged reactors to be loaded into the dry storage facility. The handover of the ISF-2 operating license was carried out during a ceremony held on April 26, the 35th anniversary of the Chernobyl accident, and was attended by Ukraine’s president, Volodymyr Zelensky.

An illustration of WIPP’s Safety Significant Confinement Ventilation System, expected to be completed in 2025. Image: DOE

Nuclear Waste Partnership (NWP), the management and operations contractor for the Department of Energy’s Waste Isolation Pilot Plant in southeastern New Mexico, announced that it has awarded a subcontract valued at approximately $163 million to The Industrial Company (TIC) to complete the construction of the transuranic waste repository’s Safety Significant Confinement Ventilation System (SSCVS).

Waste handlers take radiological readings as a crane lifts containers from a TRUPACT-II cask in the contact-handled waste bay at WIPP. Photo: DOE

The Waste Isolation Pilot Plant in southeastern New Mexico is once again accepting shipments and processing transuranic waste following a two-month annual maintenance outage. According to the Department of Energy, WIPP is back to accepting five waste shipments per week, with post-pandemic plans to increase shipments to 10 per week.

Indian Point nuclear power plant in Buchanan, N.Y.

The State of New York will withdraw its lawsuit against the transfer of Indian Point’s license to Holtec International for decommissioning under a provisional agreement signed on April 14. In exchange, Holtec has agreed to maintain a minimum of $400 million in Indian Point’s decommissioning trust fund for the next 10 years.

Federal and contractor officials participate in a groundbreaking ceremony for the WEPAR project on April 7 at the Y-12 National Security Complex in Oak Ridge. Photo: DOE

A project to reduce by approximately half the high-security protected area at the Department of Energy’s Y-12 National Security Complex in Oak Ridge, Tenn., will avoid millions of dollars in costs and accelerate cleanup, the DOE’s Office of Environmental Management (EM) announced.

A retired USGS geologist shares his experience of working on the publicly misunderstood nuclear waste repository and its geology.

The author on a typical day at Yucca Mountain, with Solitario Canyon and the flat-topped repository block seen in the background.

SRNS engineers (from left) Will Jolin, John Bradley, and Joao Cardoso-Neto discuss a plan to move and repurpose equipment used at 19 soil cleanup sites. Photo: DOE

A project to passively remove nonradioactive contaminants from the soil and groundwater at the Department of Energy’s Savannah River Site in South Carolina is coming to an end, as workers prepare to remove solar-power “plugs” from 19 soil remediation locations at the site.

The NRC-licensed independent spent fuel storage installation at Zion, Ill.

A radiological worker surveys the inside of a TRUPACT-II containment lid during waste handling operations at WIPP. Photo: DOE

Crews move equipment used to inspect drums holding diluted plutonium into a storage site in K Area at the Savannah River Site. Photo: DOE

Workers at the Department of Energy’s Savannah River Site in South Carolina recently finished transferring equipment to the site’s K Area in preparation of shipping downblended plutonium to the Waste Isolation Pilot Plant in New Mexico for disposal. The plutonium is part of the 34 metric tons of surplus plutonium the National Nuclear Security Administration plans to ship to WIPP under the “dilute and dispose” option the department adopted following the cancellation of the MOX Fuel Fabrication Facility project.

Workers remove asbestos siding panels from a Portsmouth Gaseous Diffusion Plant building. Photo: Business Wire

Fluor-BWXT Portsmouth, a joint venture of Fluor and BWX Technologies, along with engineering company Jacob, have received a contract extension valued at up to $690 million, including options, from the Department of Energy. The contract, announced April 6, is for environmental management work at the former Portsmouth Gaseous Diffusion Plant near Piketon, Ohio.

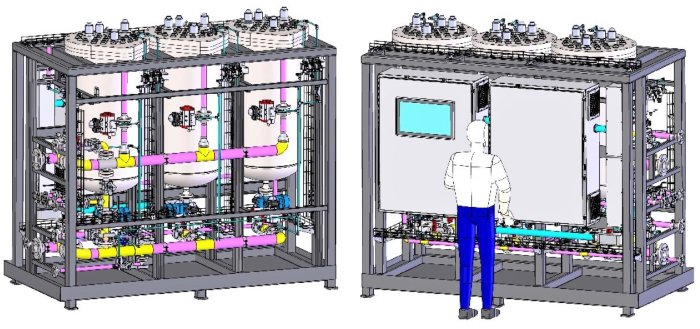

A front-and-back illustration of the new Hanford ETF filter system, which is intended to eliminate the need to shut down operations every 12 hours to replace filters during wastewater processing. Image: DOE

A new wastewater filter system being installed at Hanford’s Effluent Treatment Facility (ETF) is expected to increase waste processing throughput, improve efficiency, and save money as the site in southeastern Washington gears up to treat tank waste, the Department of Energy announced.