Producing packages for radioactive materials takes time, attention to detail, and a thorough commitment to quality assurance.

The Optimus-H transport cask on display at the 2020 Waste Management Conference in Phoenix, Ariz.

Jeff England, director of transportation projects for NAC International, pointed to the large stainless steel canister, which looked like a giant-sized silver dumbbell, perched on the flatbed of a semitrailer truck parked in the middle of the expansive exhibit hall in the Phoenix Convention Center. NAC, a provider of nuclear storage, transportation, and consulting services, was using the 2020 Waste Management Conference, held March 8–12 in Phoenix, Ariz., to unveil its newest transport casks, the Optimus-H and Optimus-L.

“These are a different niche,” England said of the casks, which were designed to transport radioactive materials, including remote-handled transuranic waste, high-activity intermediate-level waste, low-enriched uranium, and fissile materials. “You have a lot of [small] drum-sized packages, and you also have a lot of big packages that will hold around 10 55-gallon drums. But there’s not anything in between. We hold a 110-gallon drum capacity.”

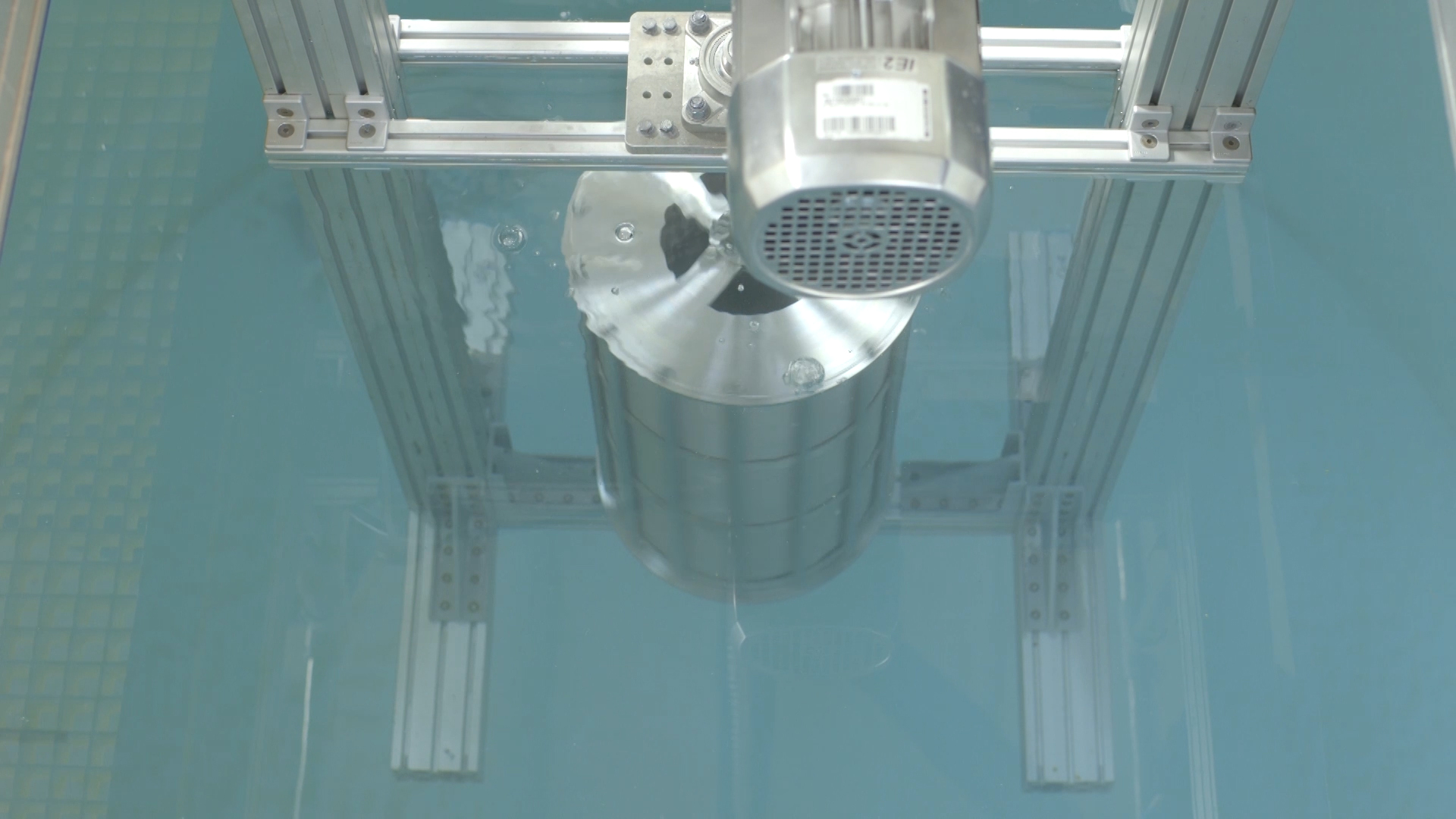

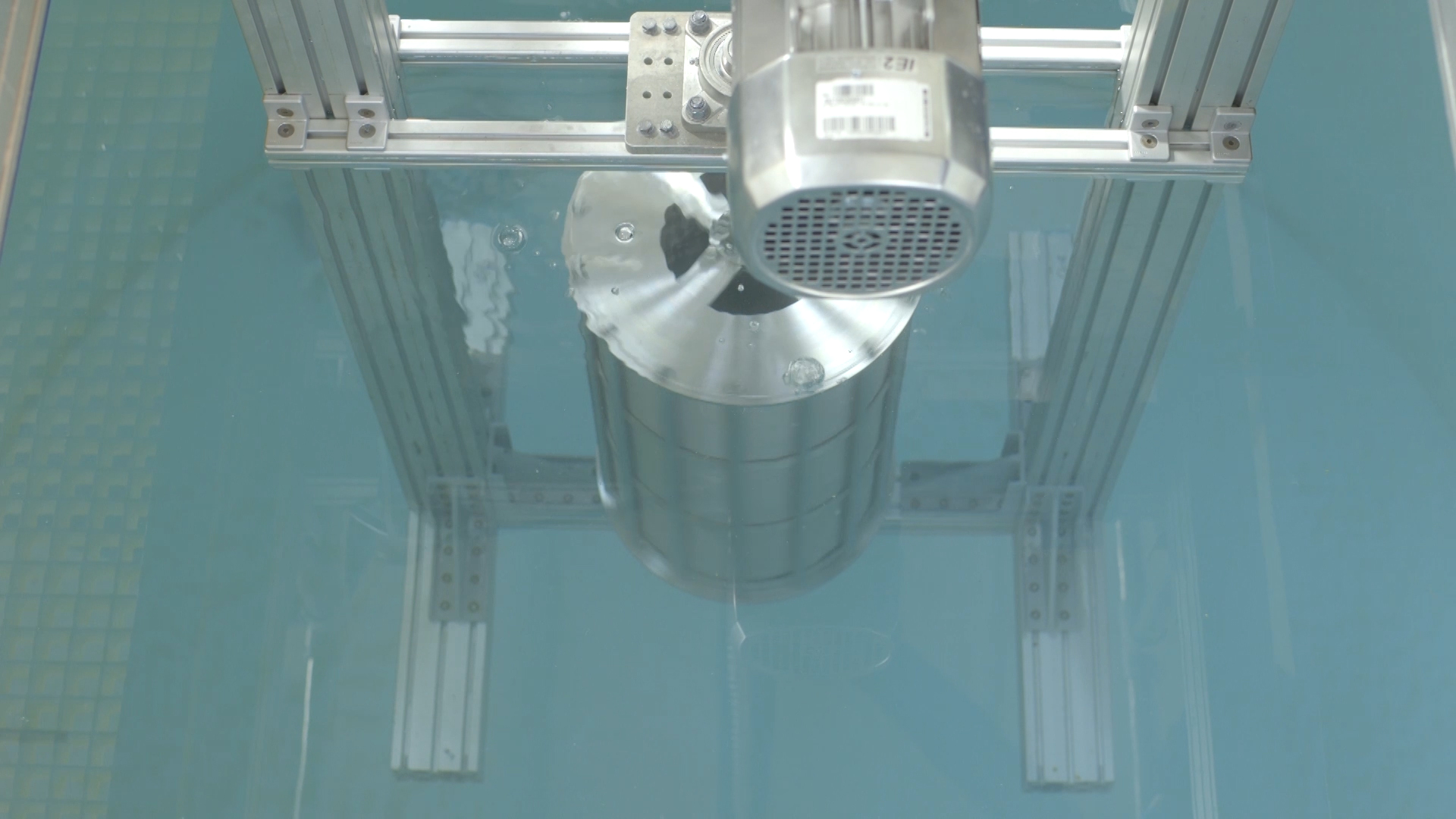

Thinking outside the box, the nuclear sector puts a new spin on a pharmaceutical tool.

Large-scale testing is done on the Spinionic rotating bed reactor system.

We live in a world where we are continually driven to increase efficiency while decreasing costs—to do more with less. The nuclear industry is no different. Developing innovative techniques or adapting creative ideas found in other industries can support that pursuit to reduce cost and, in this case, volumes of waste, while providing program certainty. Such actions build confidence in our industry and allow nuclear power to continue to be part of the narrative of our clean-energy future.

ASME Best Oral Presentation/Paper Waste Management 2019

March 10, 2020, 9:02AMRadwaste SolutionsThao Do, Jiju Joseph, Giles Whitaker, Barb Noye, Vasile Bostan, Don Jarron, and J. Clara Wren As nuclear power plants age and retire from service, many countries face significant challenges concerning the safe long-term storage and disposal of large volumes of low- and intermediate-level radioactive wastes (L&ILW). In Canada, Ontario Power Generation (OPG) is currently in the process of obtaining regulatory approval for a deep geological repository (L&ILW DGR) for such wastes from decommissioning and refurbishment of its heavy water reactors. OPG is exploring innovative methods and technologies to improve safety and reduce the processing, transportation, and disposal costs of these wastes. The volumes of metallic waste are of particular concern, because when metal corrodes it produces hydrogen that could lead to pressure buildup in the L&ILW DGR.

ANS Best Oral Presentation/Paper Waste Management 2019

March 10, 2020, 8:42AMRadwaste SolutionsLaura Merlo-Sosa, Hugh Boniface, Richard Prokopowicz, and Sam Suppiah Heavy water is used both for moderating nuclear fission and transporting heat in CANDU reactors. As a result of heavy water use in these systems, tritium is produced in small quantities from thermal neutron activation of deuterium. The presence of tritium in the heavy water contributes to the radiation dose of the reactor staff and radioactive emission from the reactor facility. Tritium dose is usually controlled through design and operating procedures that minimize leaks and limit exposure to the tritiated water. Many of the CANDU operators have also reduced the operational tritium concentration through detritiation of the heavy water from the reactor. Detritiation is carried out in a centralized facility, such as the Tritium Removal Facility in Darlington, which provides this service to Ontario’s nuclear reactor fleet. Detritiation reduces both tritium emission and dose to workers and the public from reactor operation.

As demands for a comprehensive U.S. waste management plan increase, private vendors are certifying new SNF/HLW transportation cask designs.

A large-scale campaign to move spent nuclear fuel and high-level radioactive waste in the United States to a central repository or interim storage site does not appear to be coming anytime soon. External pressures, however, including a growing number of nuclear power plant closures and increased stakeholder demand to remove stranded spent fuel and HLW, are shifting focus to building the infrastructure needed to move large volumes of waste. This includes the design and manufacture of shielded transportation casks for shipping the waste by truck or rail.