Concept art of a Westinghouse AP300 SMR. (Image: Westinghouse)

The United Kingdom’s Department of Energy Security and Net Zero has signed off on Westinghouse’s AP300 small modular reactor earlier this month.

The 2015 CSX Transportation crude oil train derailment and fire in Mount Carbon, W. Va. (Photo: CPO Angie Vallier/U.S. Coast Guard)

We all know that nuclear energy is the best energy source available—the safest and most reliable with the lowest life-cycle carbon footprint and the lowest environmental impact of any source, according to the latest UN report (unece.org/sites/default/files/2021-11/LCA_final.pdf).

Byron nuclear power plant. (Photo: Constellation)

The Ogle County Board has approved a zoning change that designates 524 acres around the Byron nuclear power plant, located in northern Illinois, as industrial rather than agricultural.

Representatives of Urenco, the United Kingdom, the United States, Germany, the Netherlands, and the IAEA gathered at Urenco’s Capenhurst site. (Photo: Urenco)

Uranium enricher Urenco welcomed representatives from the International Atomic Energy Agency to an August 19 event to mark the creation of an IAEA Centre of Excellence for Safeguards and Non-Proliferation at its Capenhurst, England, site. Representatives of the three nations with ownership stakes in Urenco—the United Kingdom, the Netherlands, and Germany—were joined by representatives from the United States, where Urenco also operates an enrichment plant. Urenco expects the new center to be fully operational in 2025.

When consumers buy food, they cannot always detect food fraud. (Infographic: Mariia Platonova/IAEA)

The adulterating of food products for financial gain, either through dilution, substitution, mislabeling, or other action, has become a lucrative industry. And because food fraud is designed to avoid detection, gauging its financial impacts can be difficult. Experts estimate that food fraud affects 1 percent of the global food industry at a cost of about $10 billion to $15 billion a year, with some estimates putting the cost as high as $40 billion a year, according to the U.S. Food and Drug Administration.

A whale swims off the coast by Diablo Canyon nuclear power plant. (Image: PG&E)

The California legislature has signaled its intent to cancel a $400 million loan payment intended to help finance a longer lifespan for the state’s last nuclear power plant, Diablo Canyon.

The Donald C. Cook nuclear power plant. (Photo: ANS Michigan-Ohio Section)

Federal regulators began an investigation this week at the Donald C. Cook nuclear plant around the circumstances of multiple diesel generator failures. The facility continues to operate safely.

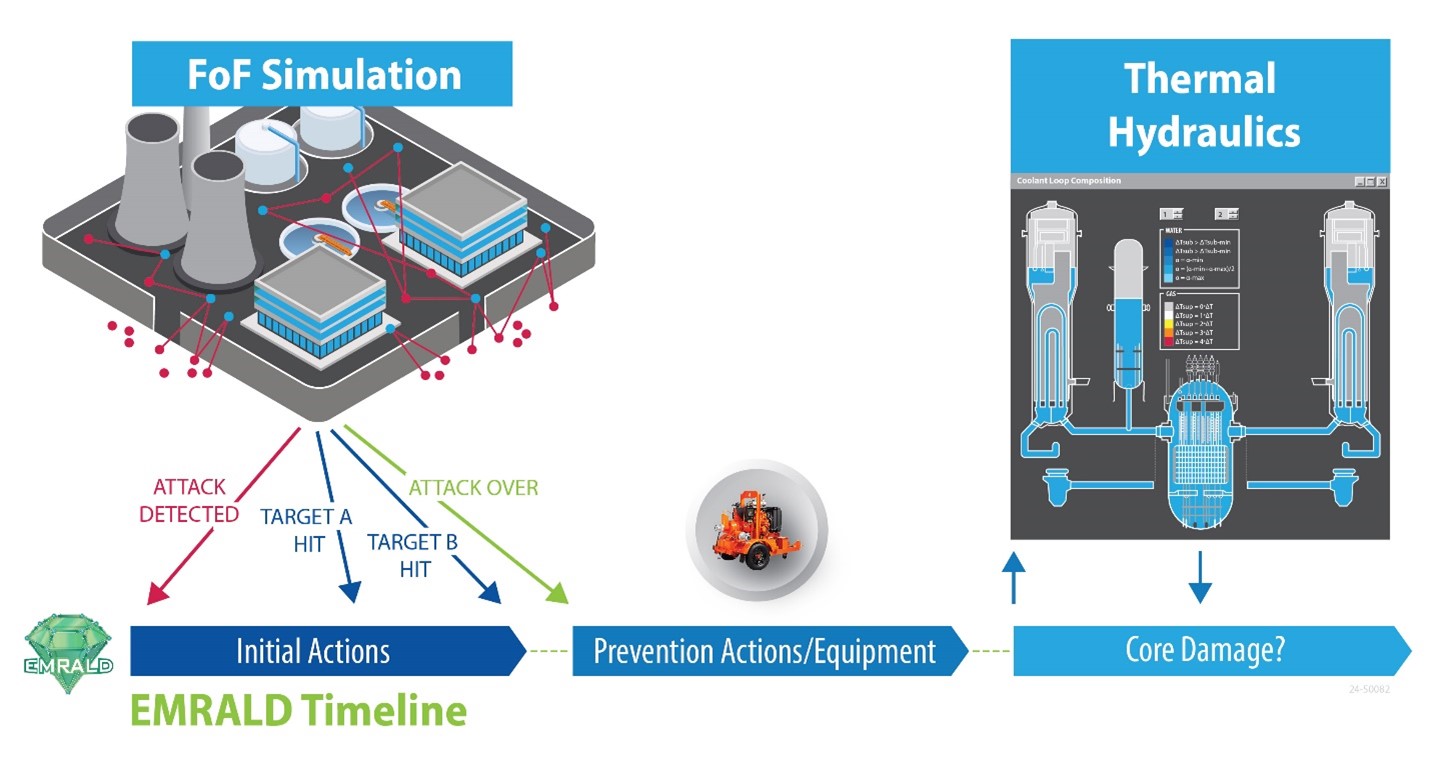

The MASS-DEF framework with prevention actions and timelines modeled in EMRALD software interacting with force-on-force (FoF) simulation and thermal hydraulics models. The risk-informed modeling in the MASS-DEF framework integrates physical security effectiveness analysis with safety measures, such as time to core damage. (Graphic: INL)

Today’s nuclear power plants are the nation’s largest source of carbon-free energy, but they come with high operating and maintenance costs.

Competition from other sources, especially natural gas, coupled with low electricity prices, has resulted in the closure of some plants in the last decade due to economic reasons.

One way to alleviate these economic pressures is to reduce the cost of operating nuclear power plants, including the costs associated with physical security.

Up-front requirements can enhance the ability to support maintenance and operations from start-up through long-term operation

It may seem counterintuitive, but the best time to enhance the ability to support operations and maintenance for a new plant is before construction starts. This is one of many lessons learned by the currently operating nuclear fleet. As construction and startup of many nuclear facilities was completed, it quickly became evident that the ability to efficiently support operations and maintenance was limited. Most of the information necessary to establish and manage procurement of spare and replacement items, maintenance, and configuration of the facilities was unavailable and had to be gathered on a case-by-case, “on-demand” basis. Absence of necessary information and the associated challenges resulted in the need for staff augmentation and multiyear-long projects to develop equipment bills of material and maintenance programs and to perform technical evaluations for the huge quantities of spare and replacement items being requested.

Matthew Jasica is a member of a small team conducting large-scale experimental testing of reactors and their components at the NSTF. (Photo: Argonne)

A facility at Argonne National Laboratory has been simulating nuclear reactor cooling systems under a wide range of conditions since the 1980s. Its latest task, described by Argonne in an August 13 news release, is testing the performance of passive safety systems for new reactor designs.

Designed as a half-scale model of a real reactor system, Argonne’s Natural Convection Shutdown Heat Removal Test Facility (NSTF) is used for large-scale experimental testing of the performance of passive safety systems, which are designed to remove decay heat using natural forces including gravity and heat convection. Those tests yield benchmarking data qualified to the level of National Quality Assurance-1 (NQA-1) that is shared with vendors and regulators to validate computational models and guide licensing of new reactors and components.

The State of Ohio and

The State of Ohio and