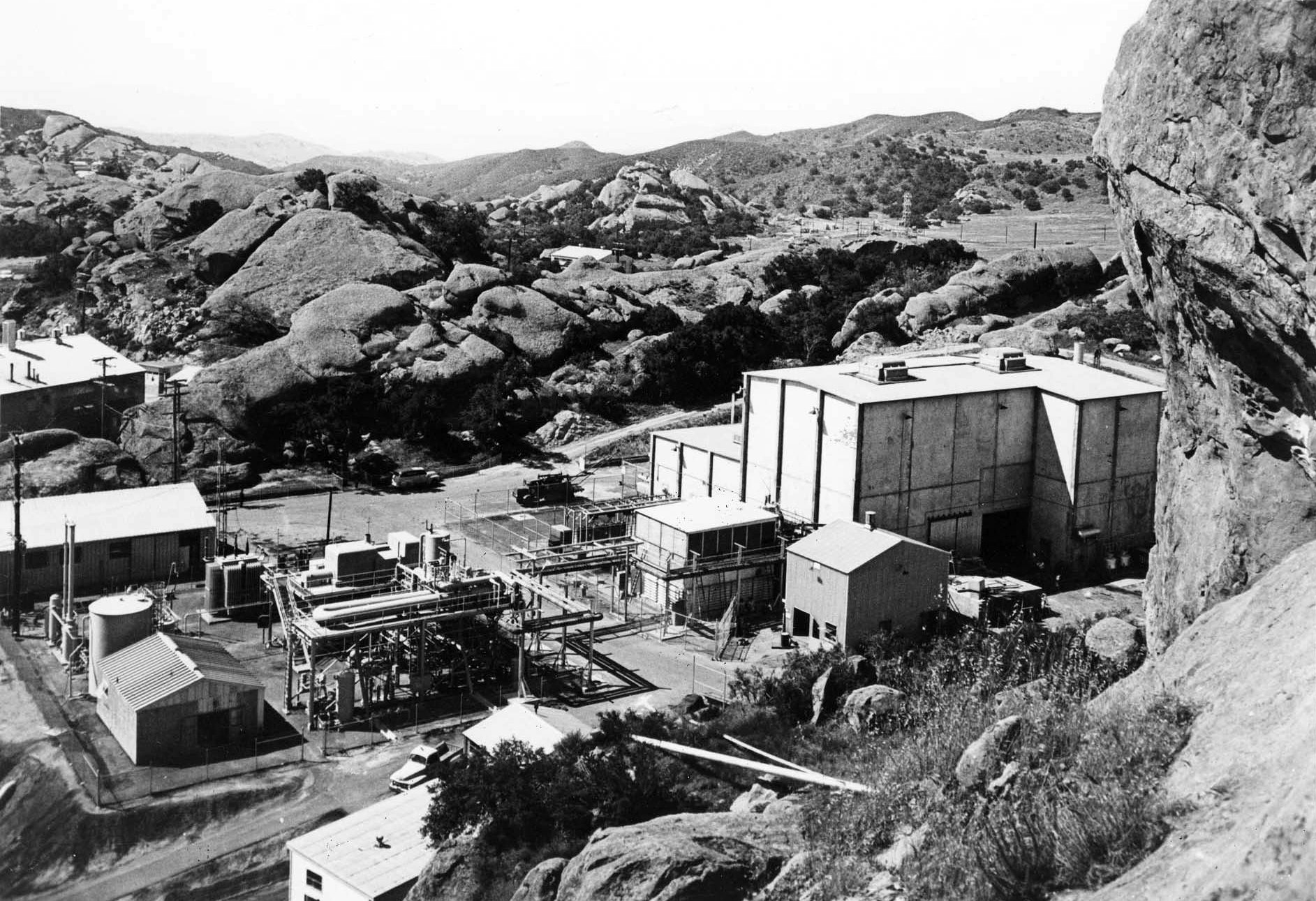

The SRE nuclear facility in 1958. (Photo: DOE)

In February 1957, construction was completed on the Sodium Reactor Experiment (SRE), a sodium-cooled, graphite-moderated reactor with an output of 20 MWt. The design of theSRE had begun three years earlier in 1954, and construction started in April 1955. On April 25, 1957, the reactor reached criticality, and the SRE operated until February 1964.

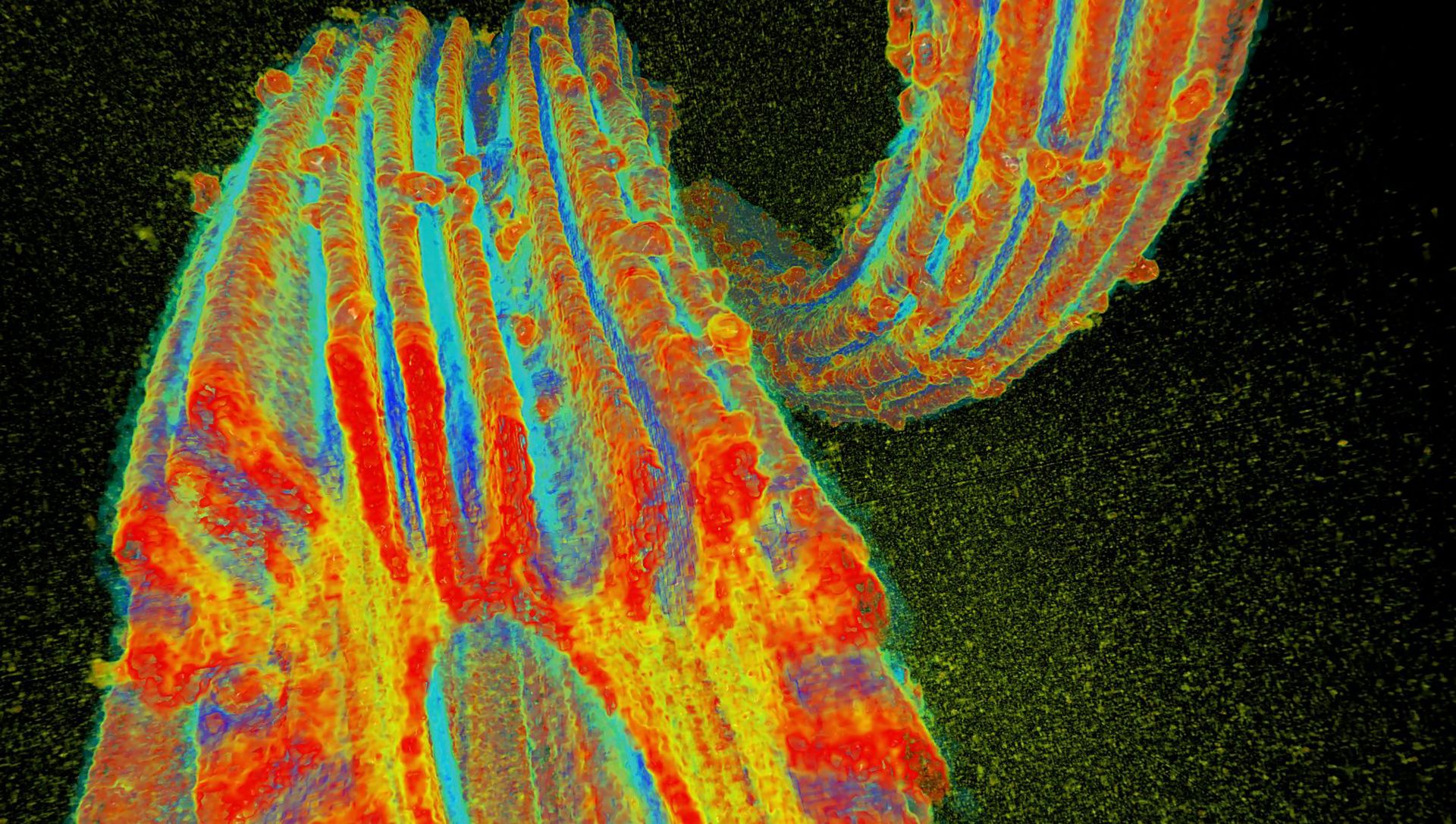

Researchers have been working frantically to develop an array of materials and fibers to economically extract uranium from seawater—and they have succeeded. PNNL scientists exposed this special uranium-sorbing fiber developed at ORNL to Pseudomonas fluorescens and used the Advanced Photon Source at Argonne National Laboratory to create a 3-D X-ray microtomograph to determine microstructure and the effects of interactions with organisms and seawater. (Image: PNNL)

America, Japan, and China are racing to be the first nation to make nuclear energy completely renewable. The hurdle is making it economical to extract uranium from seawater, because the amount of uranium in seawater is truly inexhaustible.

While America had been in the lead with technological breakthroughs from the Department of Energy’s Pacific Northwest and Oak Ridge National Laboratories, researchers at Northeast Normal University in China have sprung ahead. But these breakthroughs from both countries have brought the removal of uranium from seawater within economic reach. The only question is when will the source of uranium for our nuclear power plants change from mined ore to seawater extraction?

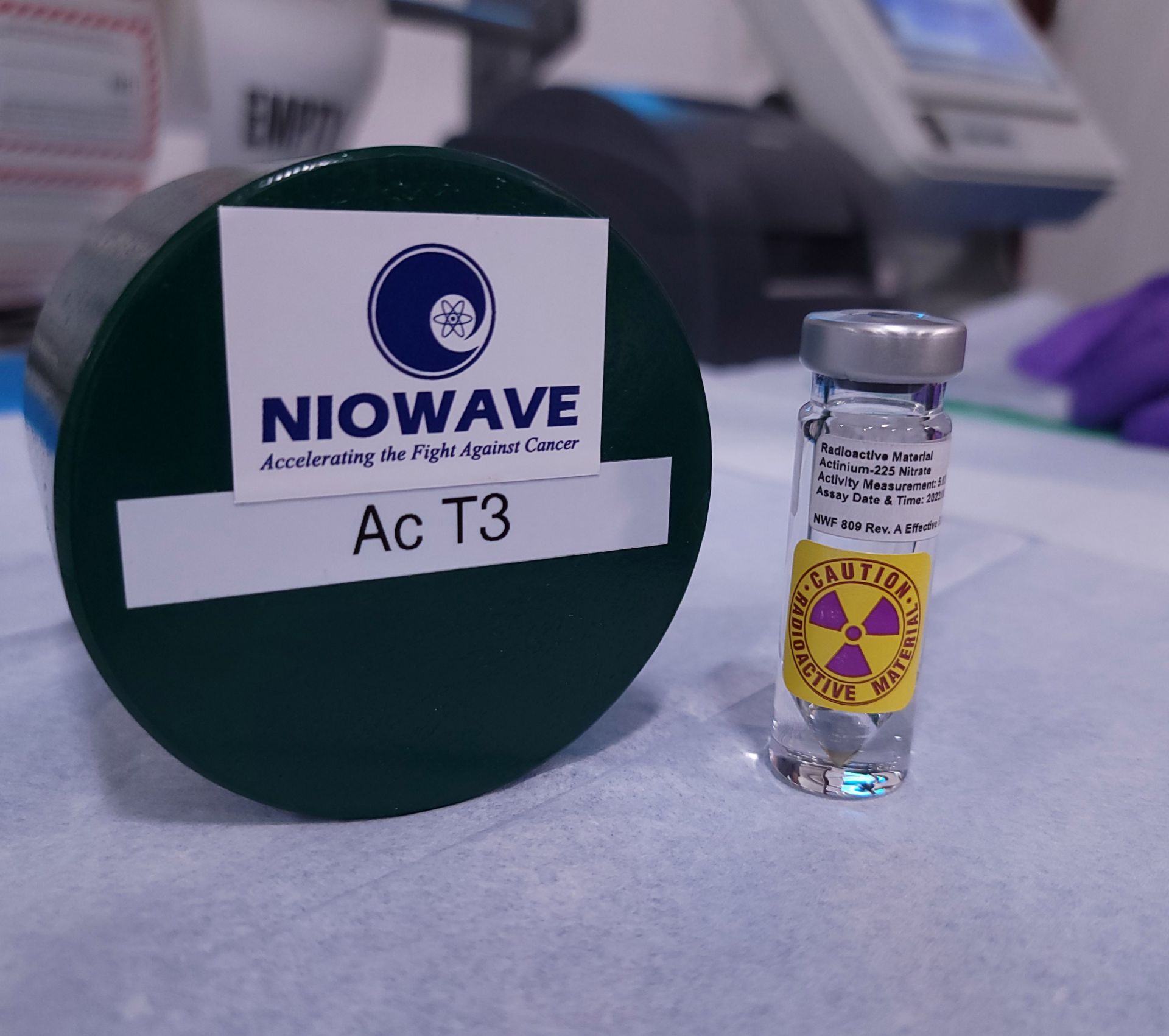

Radioisotopes target cancer, improve imaging, and have myriad other medical uses

ORNL radioisotope manufacturing coordinator Jillene Sennon-Greene places a shipment vial of actinium-225 inside the dose calibrator to confirm its activity is within customer specifications. (Photo: Carlos Jones/ORNL, DOE)

On August 2, 1946, 1 millicurie of the isotope carbon-14 left Oak Ridge National Laboratory, bound for the Barnard Free Skin and Cancer Hospital in St. Louis, Mo.

That tiny amount of the radioisotope was purchased by the hospital for use in cancer studies. And it heralded a new peacetime mission for ORNL, built just a few years earlier for the production of plutonium from uranium for the Manhattan Project.

Argonne director Paul Kearns delivers the plenary lecture on the first day of the 2023 Atoms for Humanity symposium. (Photo: Purdue NE/CHE)

The roles of nuclear energy as a clean energy source and in space exploration were highlighted at the recent Atoms for Humanity symposium, held October 25–26, 2023. The symposium, which was organized by Purdue’s Center for Intelligent Energy Systems (CiENS) and hosted by the university’s School of Nuclear Engineering, was held on the West Lafayette, Ind., campus in Eliza Fowler Hall.

A vial of Ac-225 produced by Niowave stands next to its lead shipping pig. (Photo: Niowave)

According to the Council on Radionuclides and Radiopharmaceuticals, more than 82,000 nuclear imaging procedures using nuclear medicine are performed throughout the world every day. To administer these vital medical procedures, radiopharmaceutical companies and hospitals rely on a handful of producers of medical radioisotopes.

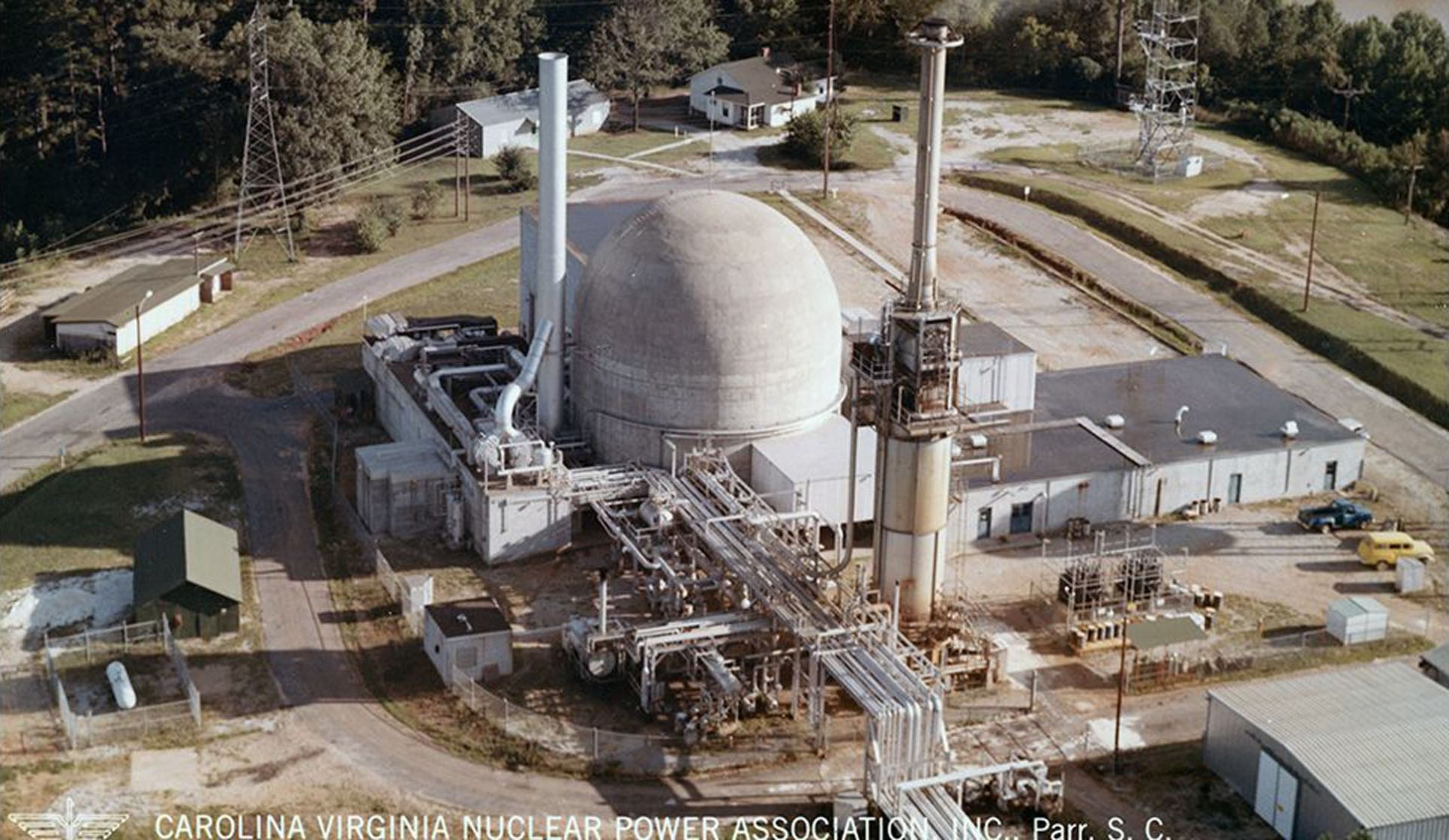

The Carolinas-Virginia Tube Reactor site, circa 1963. (Photo: Duke Energy)

The Carolinas-Virginia Tube Reactor (CVTR), also known as Parr due to its location in Parr, S.C., was a 65-MWt (17-MWe) pressurized tube reactor. Construction began in January 1960, and the reactor reached initial criticality in March 1963. Commercial operation commenced in December 1963, and the reactor was permanently shut down in January 1967 after the test program was complete.

Africa is home to 1.5 billion people in 54 countries living on 12 million square miles. The economies of many of these countries are hobbled by a general dearth of energy that nuclear could solve without adding to the harm of global warming.

The World Nuclear Association and the African Commission on Nuclear Energy (AFCONE) last year signed a memorandum of understanding to encourage the use of nuclear energy in support of economic growth and sustainable energy development in Africa.

December 15, 2023, 4:56PMNuclear NewsDonna Kemp Spangler and Joel Hiller BWXT’s microreactor components would be designed to be transported directly from the factory to the deployment site. (Image: BWXT)

“The tools of the academic designer are a piece of paper and a pencil with an eraser. If a mistake is made, it can always be erased and changed. If the practical-reactor designer errs, he wears the mistake around his neck; it cannot be erased. Everyone sees it.”

Many in the nuclear community are familiar with this sentiment from Admiral Rickover. A generation of stagnation in the industry has underscored the truth of his words. But as economies around the world put a price on carbon emissions, there’s a renewed sense of urgency to deploy clean energy technologies. This shifts the global balance of economic competitiveness, and it’s clear that the best path forward for nuclear requires combining the agility of private innovators with the technology and capabilities of national laboratories.

Carson Noack poses alongside the NEXT Lab’s Molten Salt Test System drainage tank, for which he played a key role in designing and fabricating.

(Photo: Kamryn Kelly)

Carson Noack is a busy young man with a clear vision of the future of energy. The 23-year-old undergraduate is slated to receive his bachelor’s degree in mechanical engineering from Abilene Christian University (ACU) in 2024. He’s also a researcher in the university’s Nuclear Energy eXperimental Testing (NEXT) Laboratory, which has been making news with its plans to build the first new research reactor in the United States in more than 30 years—the Molten Salt Research Reactor (MSRR).

-3 2x1.jpg)