The NuScale control room simulator has been used to showcase the plant’s design, prototype new displays, and test the operator and supervisor procedures in a fully digital control room. (Photos: NuScale Power)

Since the inception of commercial nuclear power in the United States, every control room in every nuclear plant has looked essentially the same. You will see fixed alarm tiles, red and green lights, rows of switches, and analog meters. Until about a decade ago, you would even have seen paper charts (now replaced by digital versions of those same charts). Licensed operators have shown through a proven operating history that this control room design is safe and effective. Genius definitely went into the complexity of circuits and placement of switches and indications in the design, but things have come a long way over the years, and new technology, updated plant designs, and the need to improve efficiency and maintain reliability have impacted staffing and the role of operators. A control room update is long overdue. So, what lies ahead for the future of nuclear control room design? What possibilities exist for the next generation of plants?

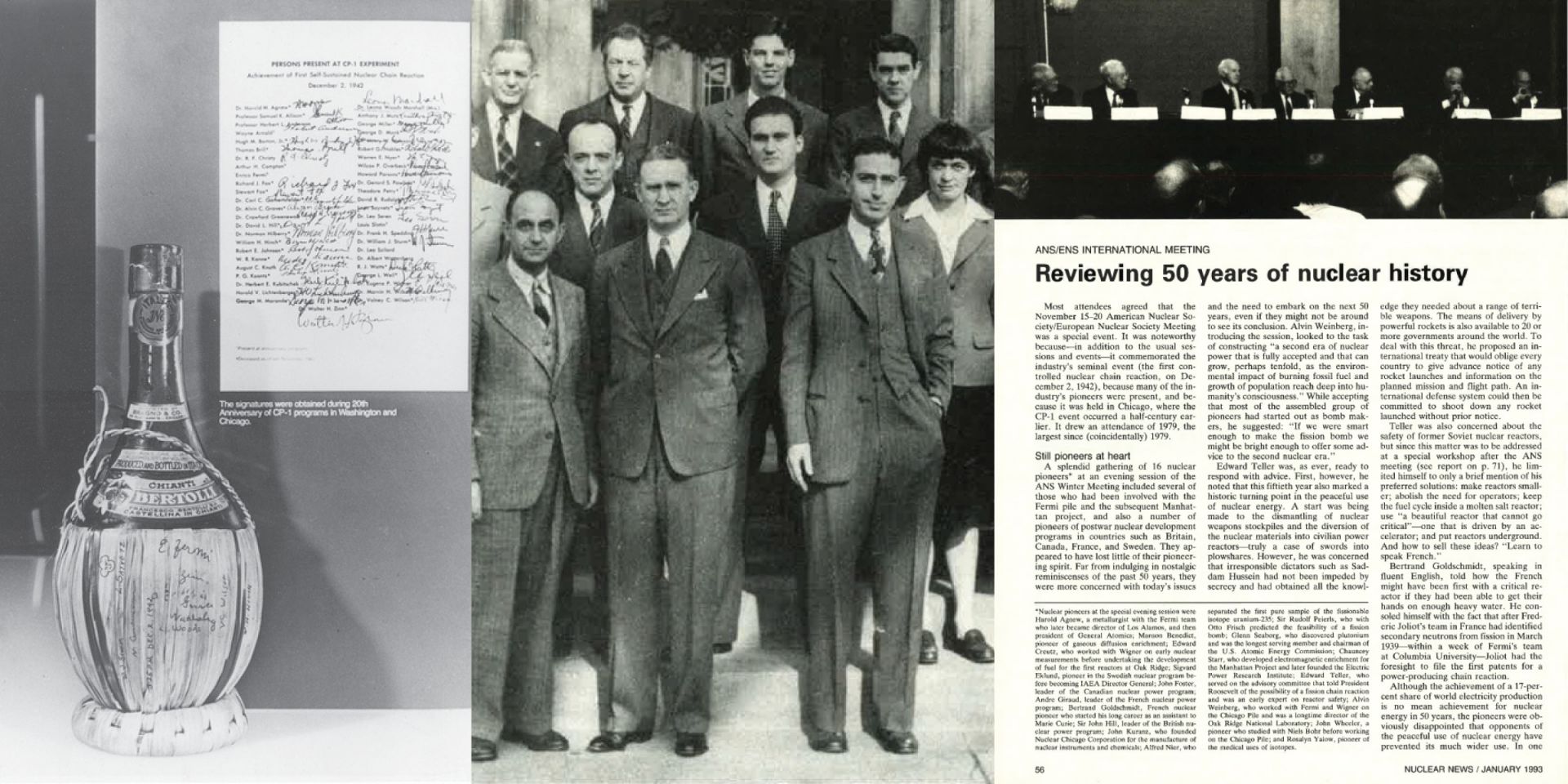

A replica of the chianti bottle signed by many of those present on December 2, 1942, alongside the image of a document signed 20 years later by most of those present (Photo: ANL); a portion of a photo of CP-1 scientists taken on December 2, 1946 (Photo: ANL); January 1993 Nuclear News coverage of CP-1 50th anniversary commemorations during the 1992 ANS Winter Meeting.

Nuclear Newswire is back with the final #ThrowbackThursday post honoring the 80th anniversary of Chicago Pile-1 with offerings from past issues of Nuclear News. On November 17, we took a look at the lead-up to the first controlled nuclear chain reaction and on December 1, the events of December 2, 1942, the day a self-sustaining nuclear fission reaction was created and controlled inside a pile of graphite and uranium assembled on a squash court at the University of Chicago’s Stagg Field.

December 2, 2022, 3:03PMNuclear NewsBrian Dassatti, Kamila Blain, and Jenn Sinkiewicz Teledyne FLIR PackBot® conducts visual inspections in a hazardous area.

Mobile unmanned systems, also known as MUS, encompass a range of robotic devices, including drones, ground vehicles, crawlers, and submersibles. They are used for a wide range of industrial and defense applications to automate operations and assist humans or completely remove human workers from hazardous conditions. Robotics are ubiquitous in industrial manufacturing. Military robots are routinely employed in combat support applications, such as reconnaissance, inspection, explosive ordnance disposal, and transportation. Drones are used in many industries for security and monitoring, to conduct aerial inspections or surveys, and to capture digital twins. Wind and solar farms use MUS technologies for day-to-day operations and maintenance.

Demolition and disposal shifted into high gear this spring at the DOE’s former uranium enrichment plant in Ohio.

In the 1950s, the U.S. Department of Energy constructed the Portsmouth Gaseous Diffusion Plant in rural southern Ohio to enrich uranium, alongside two other federally owned and managed facilities in Oak Ridge, Tenn., and Paducah, Ky. The Cold War-era plant was built as a self-sufficient industrial city with more than 400 buildings and facilities centered around three massive gaseous diffusion process buildings that could enrich the level of the uranium-235 isotope for nuclear fuel in the defense and energy sectors.

The opening session of ICGR-6. (Photo: OECD NEA)

While deep geological repositories (DGRs) are the globally preferred and scientifically proven solution to store high-level radioactive waste, societal challenges remain. Given the long time frames associated with DGR development and implementation, and a rise in global interest in nuclear energy to meet urgent climate mitigation targets, building and maintaining human capacity is now even more of a priority.

The decommissioning of ORNL’s aging research reactors is clearing the stage for future missions at the site.

An aerial photograph of Oak Ridge National Laboratory’s “Reactor Hill,” with, from left to right, reactor buildings 3042, 3005, and 3010. The DOE and its contractors are removing these excess contaminated facilities to eliminate risks and clear land for future research missions. (Photos: UCOR)

The Department of Energy and its environmental cleanup contractor United Cleanup Oak Ridge (UCOR) are poised to meet critical milestones as they continue to move to the next generation of cleanup at Oak Ridge National Laboratory in Tennessee. On ORNL’s main campus, crews on “Reactor Hill”—so named because of the four remaining reactor facilities on that hillside—and at the Experimental Gas-Cooled Reactor (EGCR) just east of the campus continue rigorous schedules as they enter a new phase of progress in the cleanup program.

Caption. (All photos: Duke Energy)

Duke Energy’s Harris nuclear power plant’s 24th refueling outage began in early October. The plant, located in New Hill, N.C., is a 964-MWe Westinghouse three-loop pressurized water reactor that started commercial operation in May 1987.

Energy Harbor’s Beaver Valley plant, located on the Ohio River near Shippingport, Pa. (Photo: Energy Harbor)

Two critical factors for the success of nuclear industry outages are safety and efficiency. This includes personal and nuclear safety for the team members working on the outage, equipment safety through proper inspections and maintenance, and ultimately public safety when a reactor system is returned to service, free of defects and ready for reliable power production.

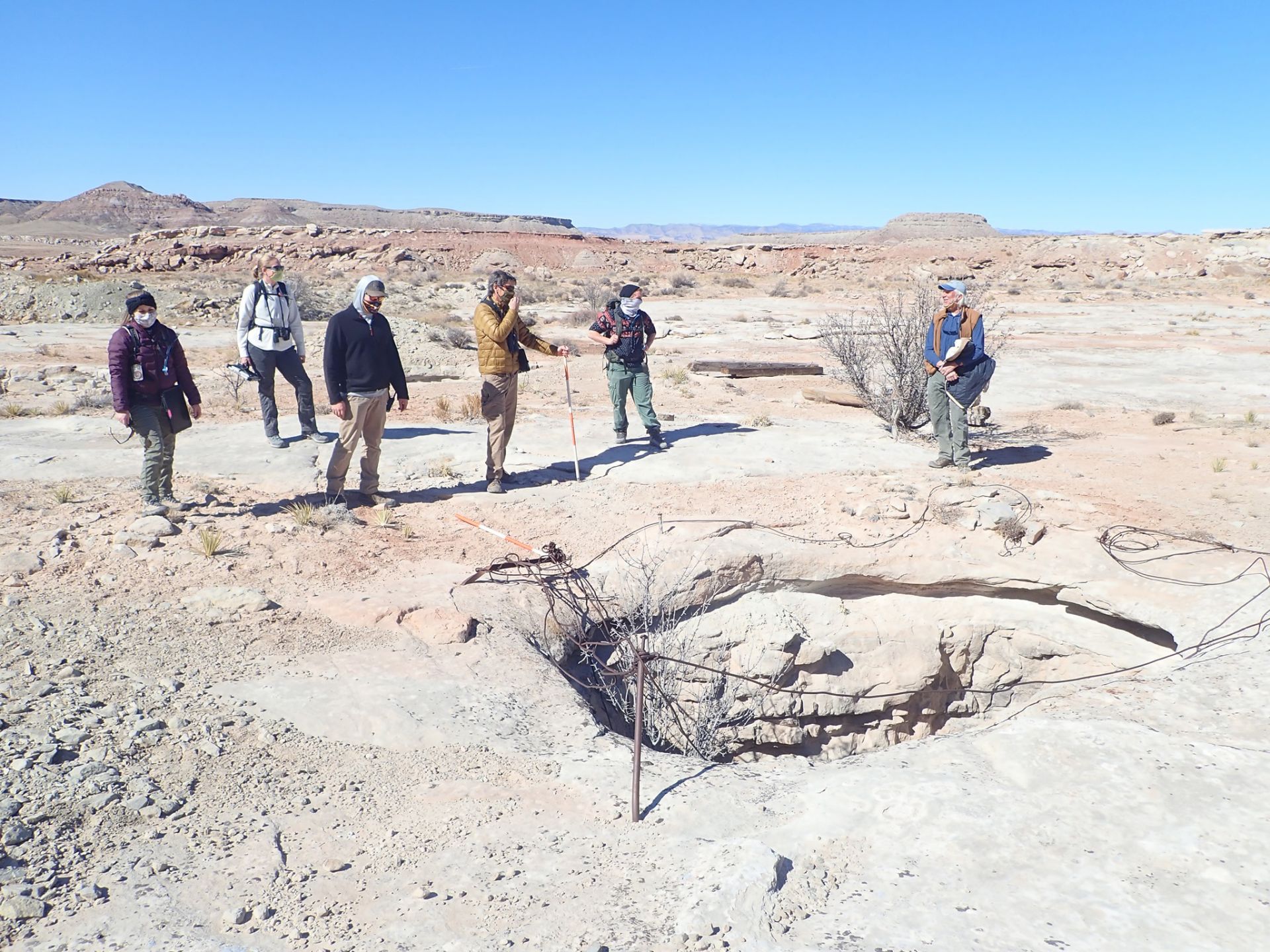

DRUM team members at the Telluride 18 mine in the Yellow Cat area of southwest Colorado.

Based on a review of U.S. Atomic Energy Commission (AEC) records and available data from numerous agencies, there are an estimated 4,225 mines across the country that provided uranium ore to the U.S. government for defense-related purposes between 1947 and 1970. To aid in the cleanup of these legacy uranium mines and establish a record of their locations and current conditions, the Defense-Related Uranium Mines (DRUM) program was established within the Department of Energy’s Office of Legacy Management (LM).

ANS Standards Committee publishes new standard for light water reactor risk-informed, performance-based design

The new standard ANSI/ANS-30.3-2022, Light Water Reactor Risk-Informed, Performance-Based Design, has just been issued by the American Nuclear Society. Approved by the American National Standards Institute (ANSI) on July 21, 2022, the standard provides requirements for the incorporation of risk-informed, performance-based (RIPB) principles and methods into the nuclear safety design of commercial light water reactors. The process described in this standard establishes a minimum set of process requirements the designer must follow in order to meet the intent of this standard and appropriately combine deterministic, probabilistic, and performance-based methods during design development.

The Effluent Management Facility, part of the Waste Treatment and Immobilization Plant at the Hanford Site. (Photo: Bechtel National)

This spring, the U.S. Government Accountability Office (GAO) released an insightful report reviewing and summarizing the status and performance of the largest projects and operations within the Department of Energy’s Office of Environmental Management (EM), which is responsible for the cleanup of hazardous and radioactive waste at sites and facilities that have been contaminated from decades of nuclear weapons production and nuclear energy research.