“The main ambition of this initiative is to test fast reactor fuels in their weakest state to better understand their limits and inform the development of improved designs,” said Colby Jensen, INL technical lead for transient testing. “Fast reactor fuel designs in the United States have not made a major leap forward since the era when the EBR-II program was shut down, and so the data from these tests of legacy fuel are highly valuable for advanced fuel designers today.”

U.S.-Japan collaboration: The safety testing is being carried out at INL’s Transient Reactor Test (TREAT) Facility under a collaboration between the DOE and the Japan Atomic Energy Agency to develop and qualify fuels for fast reactors. The tests are part of a five-year, cost-shared facility-sharing initiative between the DOE and the JAEA under the Civil Nuclear Energy Research and Development Working Group. Both agencies previously performed similar tests on high-burnup fast reactor fuel in the late 1980s before EBR-II was shut down, and TREAT was placed on standby in 1994.

According to the DOE, the agencies are testing a mixed-oxide fuel used by current Japanese fast reactor designs and a metallic alloy fuel under development in the United States and of interest to Japan. The initial experiments are expected to be completed later this year, with planning for additional testing already underway.

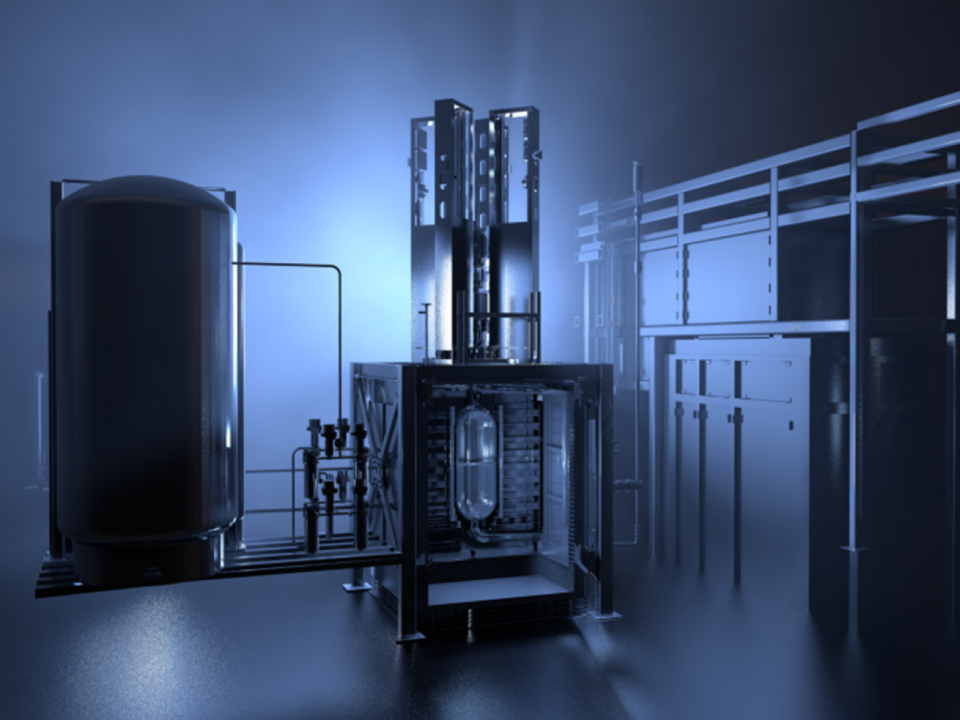

THOR in TREAT: For the tests, INL is using a new test capsule—THOR, or Temperature Heat-Sink Overpower Response—that was specifically designed to test fast reactor fuels. It uses a variety of sensors to monitor fuel behavior during testing. Testing of the capsule began in 2023, using fresh, unirradiated fuel samples.

TREAT, one of the few test reactors in the world that can perform transient tests, produces short-duration power cycles that may be more than ten times higher than a commercial power plant to help determine the safety limits of nuclear fuel. Postirradiation examination work will be performed at INL’s Hot Fuel Examination Facility and Irradiated Materials Characterization Laboratory.

_70610.jpg)